Edge-starching treatment system for knitted fabric

A processing system and technology for knitted fabrics, applied to the device for coating liquid on the surface, coating, etc., can solve the problems of waste of fabrics, achieve the effect of saving fabrics and omitting the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the scheme of the application by those skilled in the art, the scheme of the application will be further elaborated below in conjunction with the drawings and specific examples of the description. It should be understood that the embodiment of the application is an explanation of the scheme of the application, and is not intended to limit the scope of protection of the application. limited.

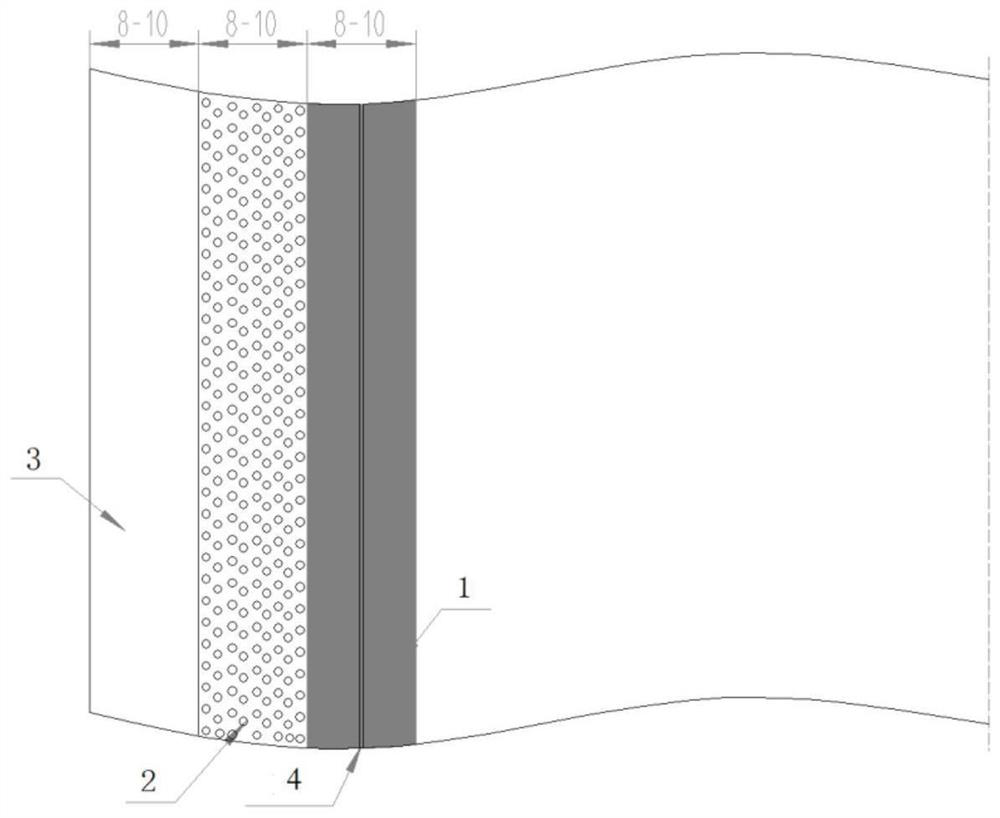

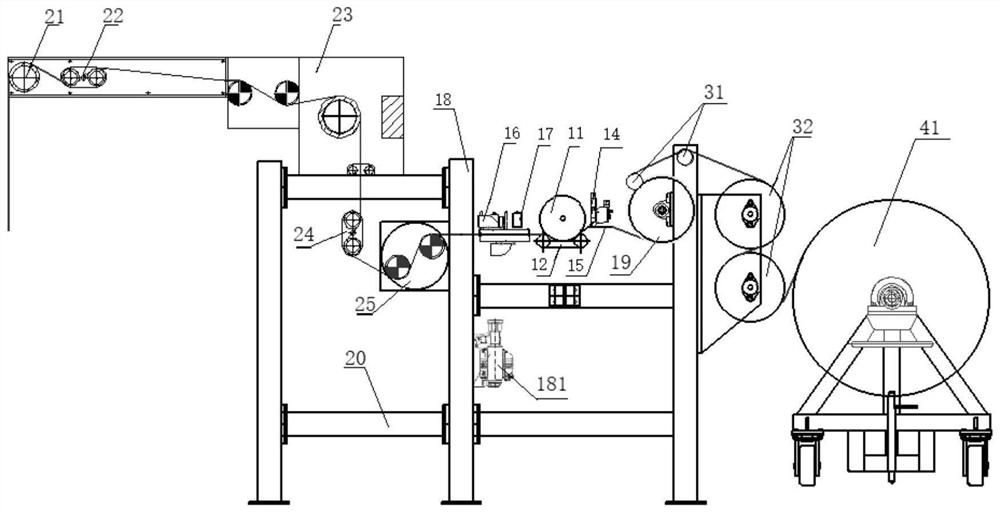

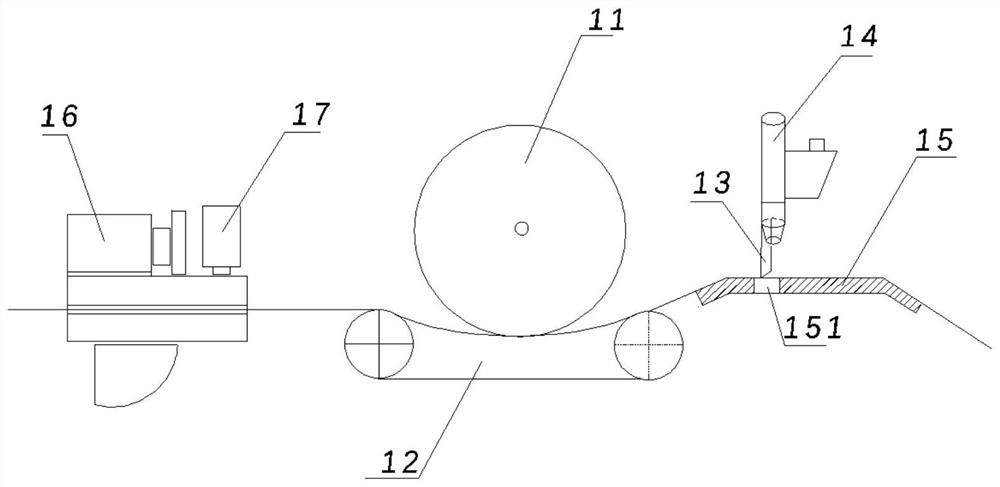

[0029] At present, the traditional "starch edge" process in the knitted fabric industry is to fix the edge of the fabric on both sides of the needle plate after stripping, overfeeding, stitching and pressing after the knitted fabric is squeezed, and then use the edge wheel on the inner side of the needle plate. The pulp edge is carried out, and then through the high temperature drying process, the water in the slurry is evaporated, and the slurry solidifies to make the fabric edge stiff, so as to achieve the effect of preventing curling. Suc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap