Rotary detonation combustion chamber suitable for gas-liquid two-phase dual fuel

A combustor and dual-fuel technology, applied in deflagration-type combustors, combustors, continuous combustors, etc., can solve the problems of poor initiation characteristics and poor stable propagation characteristics of liquid fuel rotating detonation waves, and achieve optimal injection methods, Easy to work stably and realize the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. Connected, or integrally connected; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

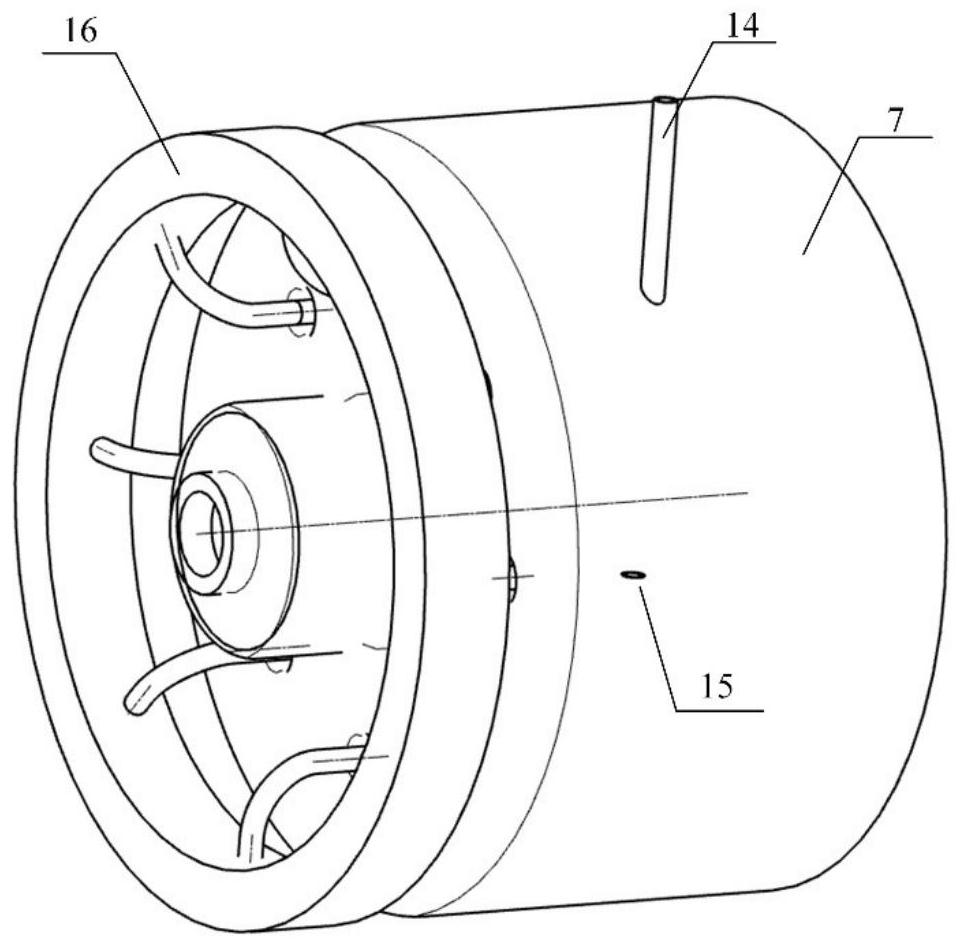

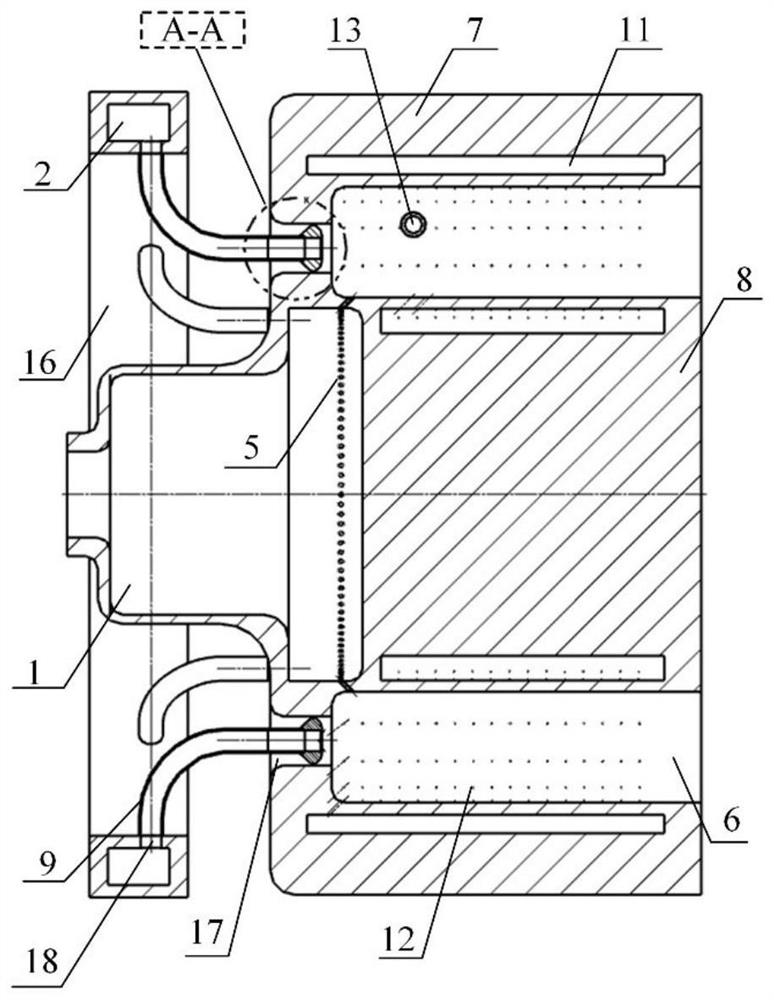

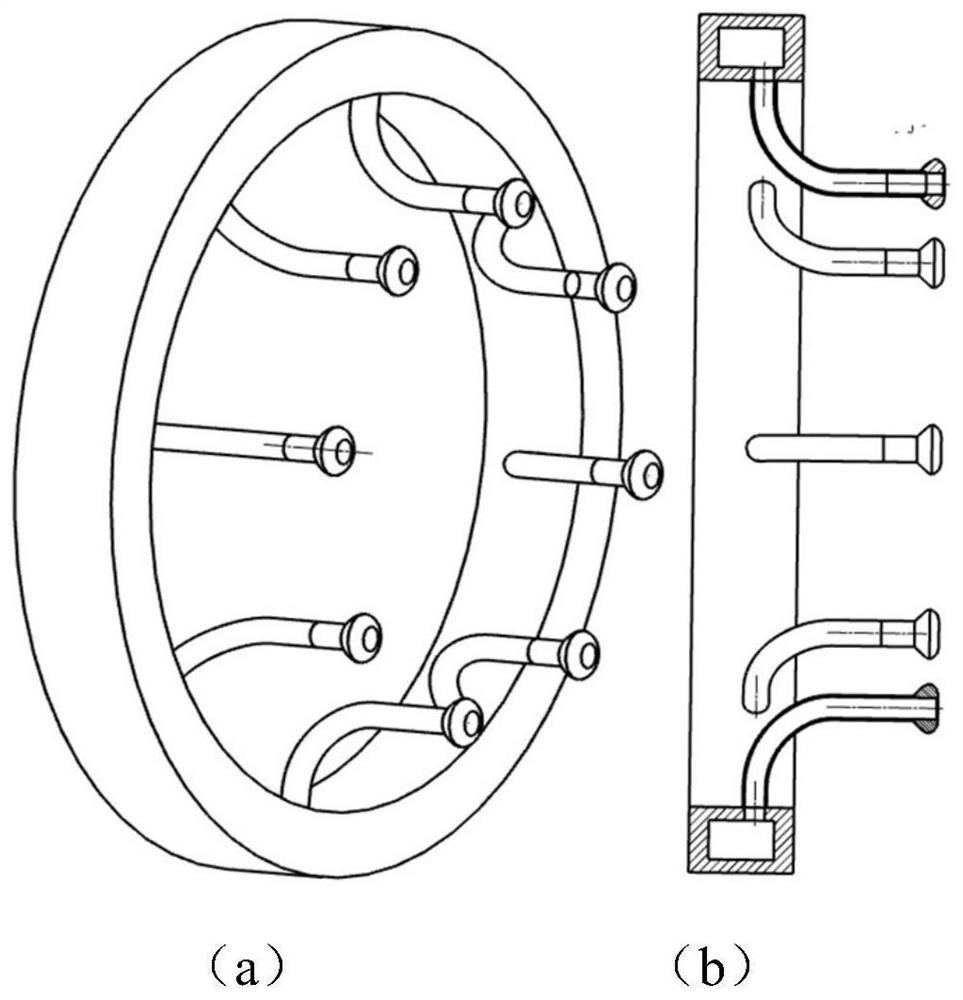

[0029] refer to figure 1 with figure 2 As shown, the present invention provides a rotating detonation combustor suitable for gas-liquid two-phase dual fuel, which is composed of a gaseous fuel supply chamber 1 , a liquid fuel supply ring chamber 2 , a combustion chamber ring chamber 6 , and film cooling holes 12 . The gaseous fuel s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap