Rapid water body sludge cleaning system and working method thereof

A technology for sludge and water bodies, which is applied in the field of rapid sludge removal systems for water bodies, can solve the problems of easy blockage of conveying pipelines, affecting the cleaning progress, and large sludge viscosity, and achieves the effect of avoiding blockage and improving the speed of sludge removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The following combined with the accompanying drawings and specific embodiments, further illustrate the present invention.

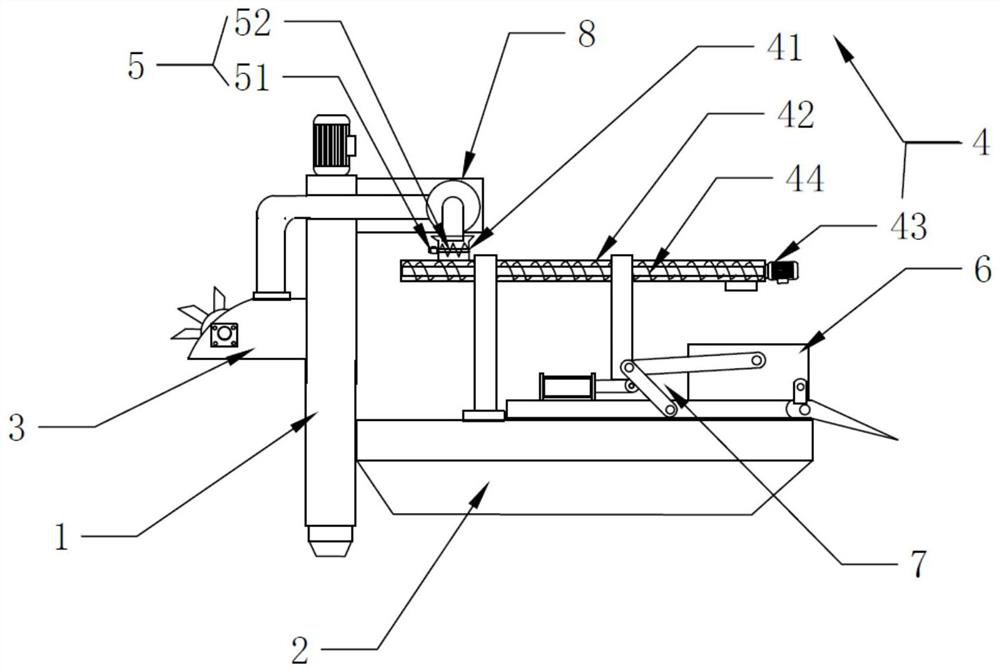

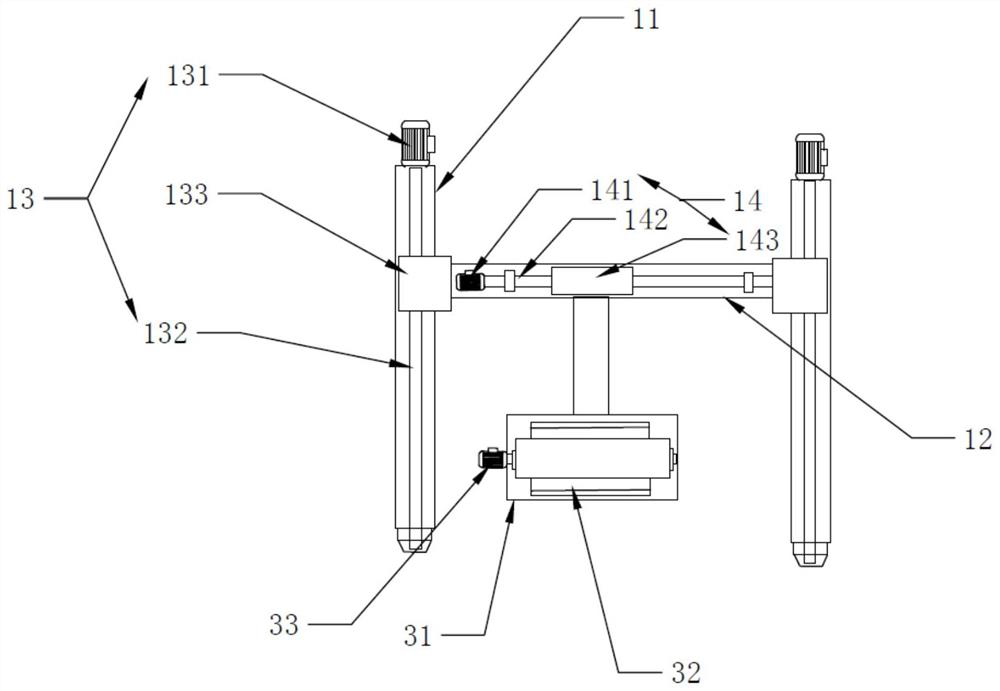

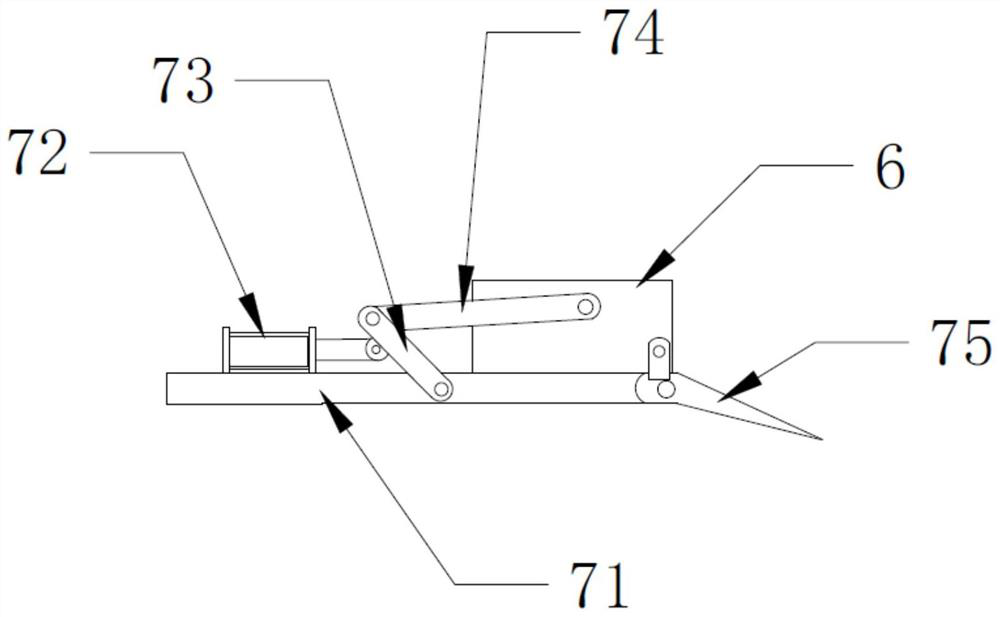

[0030] as Figure 1-3 A rapid sludge removal system for water bodies shown, including displacement adjustment and fixation

[0031] Frame 1 and hull 2, the displacement adjustment fixture 1 is installed on the side of the hull 2, the sludge digging device 3 is installed on the displacement adjustment fixture 1, the spiral feeding device 4, the crushing device 5, the sludge collection box 6 and the sludge unloading mechanism 7 are all installed on the hull 1, the silt pump 8 is located on the displacement adjustment fixture 1, the inlet port is connected with the silt digging device 3 through the pipeline, and the crushing device 5 is provided between the outlet of the sludge pump 8 and the inlet of the spiral feeding device 4, The discharge port of the spiral feeding device 4 is connected with the feed port of the sludge collection box 6, and the sludge dis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap