Battery cell manufacturing method

A manufacturing method and cell technology, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as polymetallic slag, and achieve the effect of high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and examples.

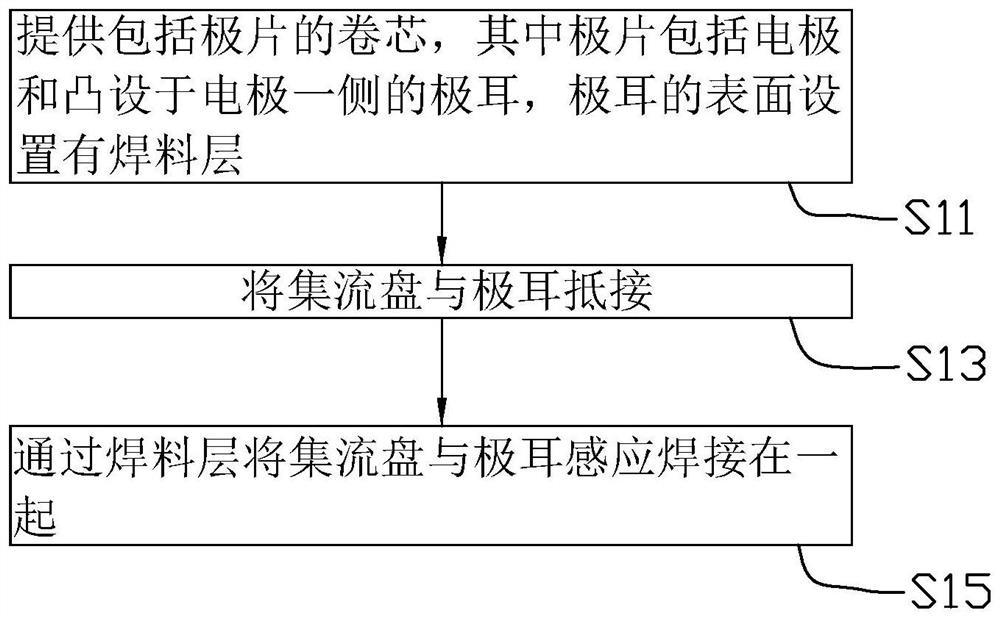

[0019] figure 1 It is a schematic flowchart of a method for manufacturing a battery cell according to an embodiment of the present invention. The embodiment of the battery cell manufacturing method includes the following steps:

[0020] S11, providing a winding core including a pole piece, wherein the pole piece includes an electrode and a pole lug protruding from one side of the electrode, and the surface of the pole lug is provided with a solder layer;

[0021] S13, abutting the current collecting plate with the tab;

[0022] S15, induction welding the current collecting plate and the tabs together through the solder layer.

[0023] In step S11, t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap