Vaporization system and semiconductor process equipment

A process equipment, semiconductor technology, applied in semiconductor/solid-state device manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of difficulty in controlling flow rate and affecting the uniformity of a single wafer of boron diffusion reaction. Multiple wafers Uniformity, reducing the uniformity of the oxidation treatment process, etc., to achieve the effect of improving efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

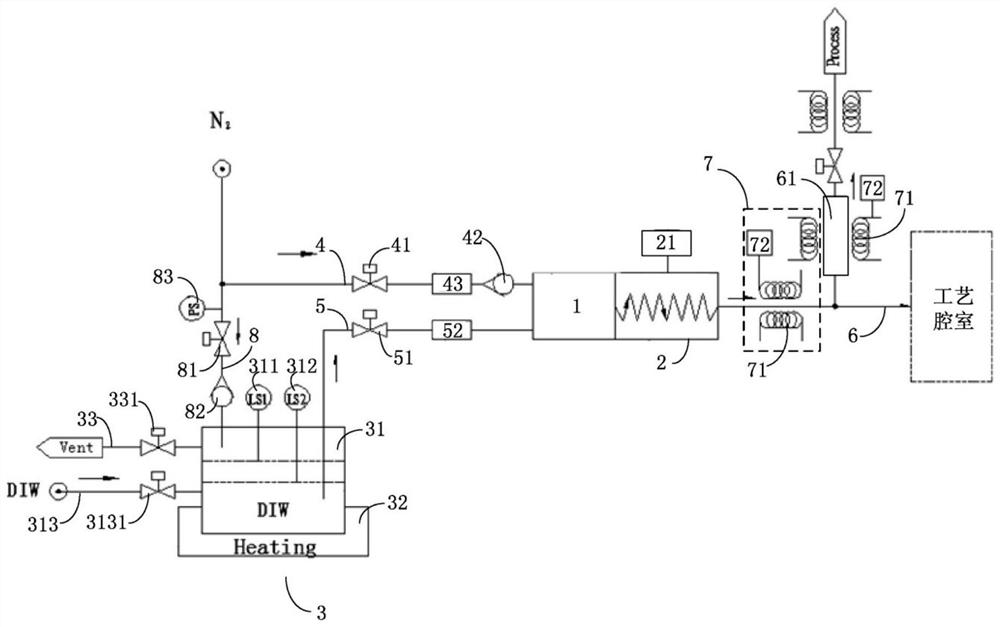

[0034] In order for those skilled in the art to better understand the technical solutions of the present invention, the vaporization system and semiconductor process equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

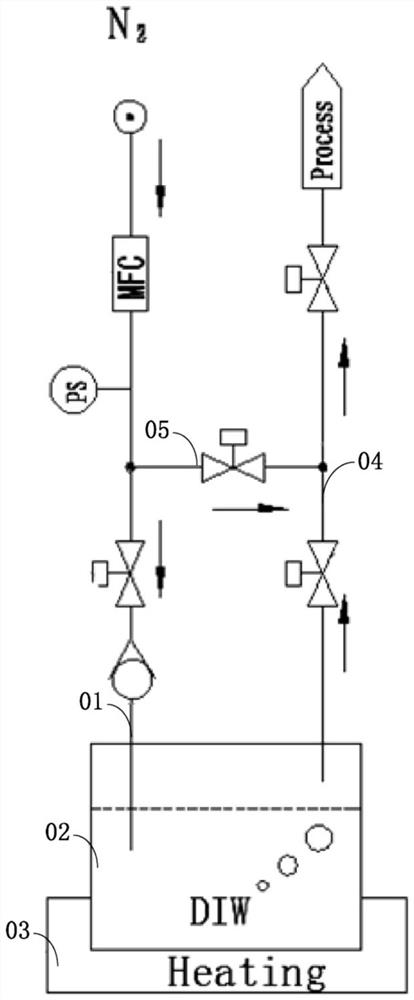

[0035] The present embodiment provides a vaporization system for delivering vapor to a process chamber of a semiconductor process equipment. Please refer to figure 2 , the vaporization system includes: jet mixer 1, mixing heater 2, process liquid source 3 and multiple pipelines. The process liquid source 3 is used for storing and outputting process liquid, and specifically, the process liquid includes deionized water.

[0036] The above-mentioned pipelines include an air inlet pipeline 4 , a liquid inlet pipeline 5 and an air outlet pipeline 6 . The first inlet of the jet mixer 1 is communicated with an external gas source through the air inlet pipeline 4, and the external gas source is used

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap