Two-port microstrip device testing device

A test device and two-port technology, applied in the direction of measuring devices, measuring device casings, components of electrical measuring instruments, etc., can solve problems such as device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

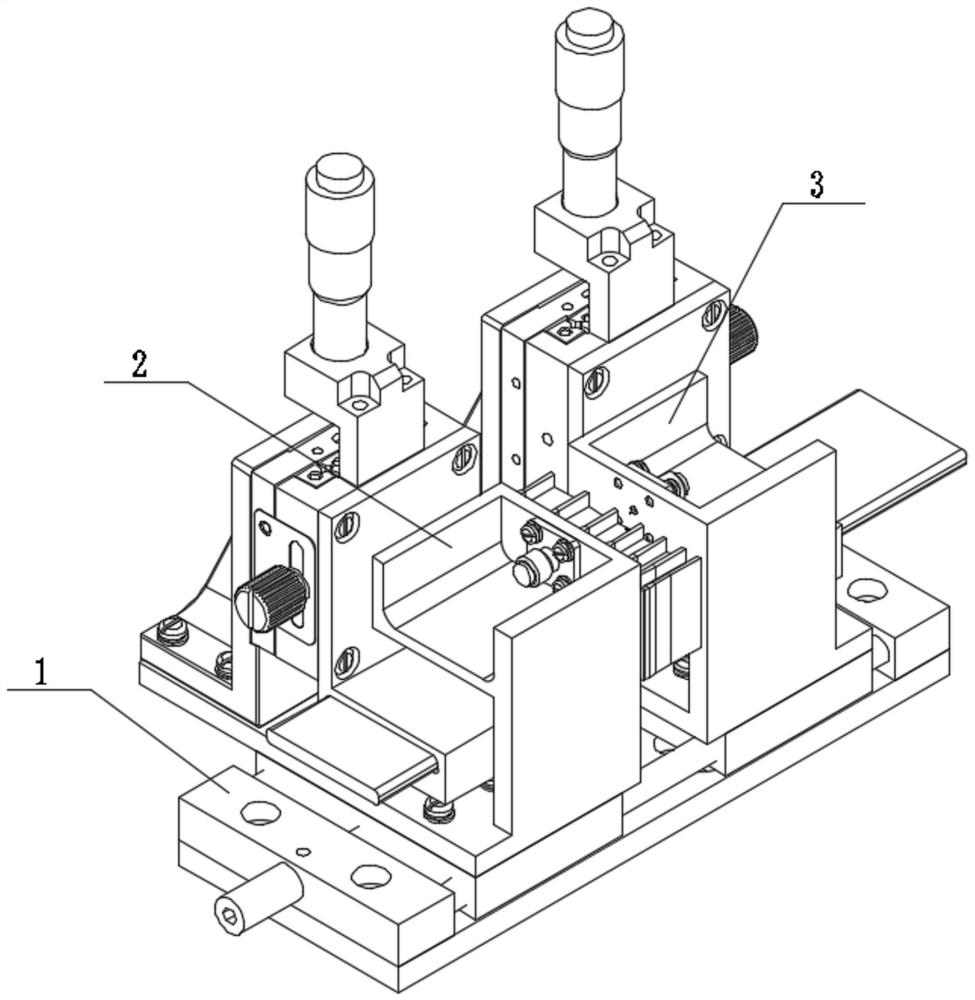

[0032] see Figure 1 to Figure 5 As shown, a two-port microstrip device testing device includes:

[0033] X-axis displacement platform 1;

[0034] The RF connector carrier A2 and the RF connector carrier B3 are arranged on the X-axis displacement platform 1, and the RF connector carrier A2 and the RF connector carrier B3 can move on the X-axis displacement platform 1 Move in the X direction.

[0035] The RF connector carrier A2 can be installed on one side of the X-axis displacement platform 1 by screws, and the RF connector carrier B3 can be installed on the other side of the X-axis displacement platform 1 by screws. The above structure mainly satisfies the movement of the radio frequency connector carrier A2 and the radio frequency connector carrier B3 in the X-axis direction.

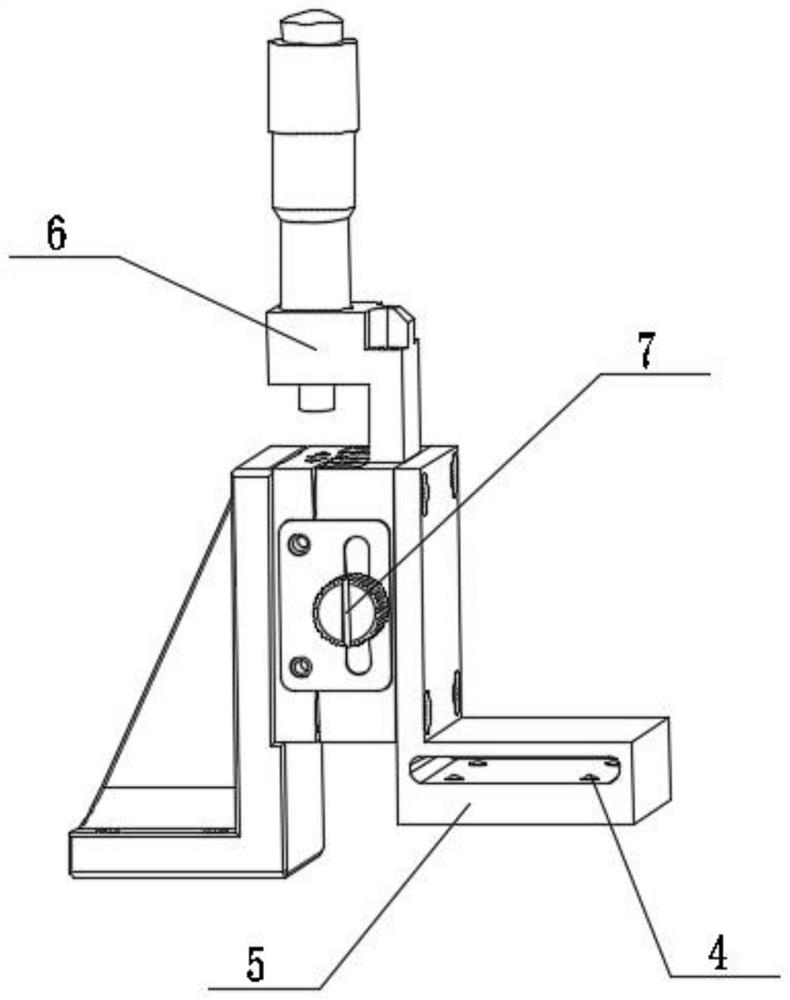

[0036] Z-axis displacem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap