Online monitoring device and method for in-situ mining of shale oil through combination of laser and supercritical water

A technology of supercritical water and in-situ mining, which is applied in the direction of mining fluid, measurement, earthwork drilling and mining, etc., can solve the problem of negligible utilization, and achieve the effect of large-scale crushing and high-efficiency in-situ mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding and implementation of the present invention by those of ordinary skill in the art, the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the embodiments described herein are only used to illustrate and explain the present invention, but not to limit it. this invention.

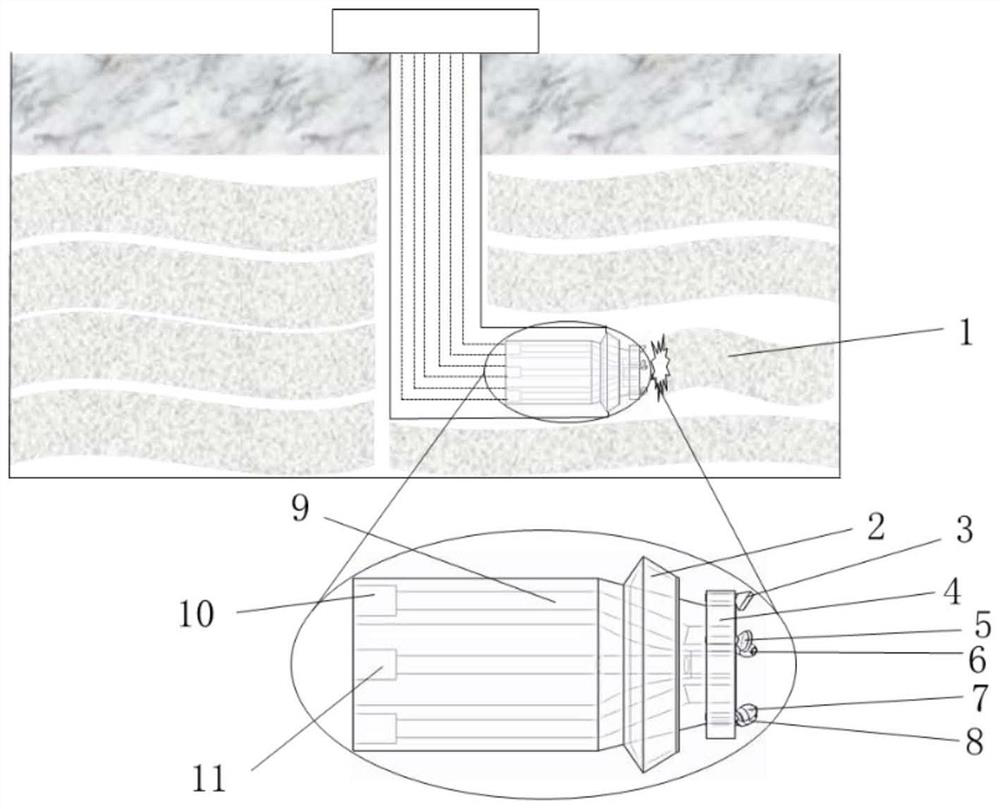

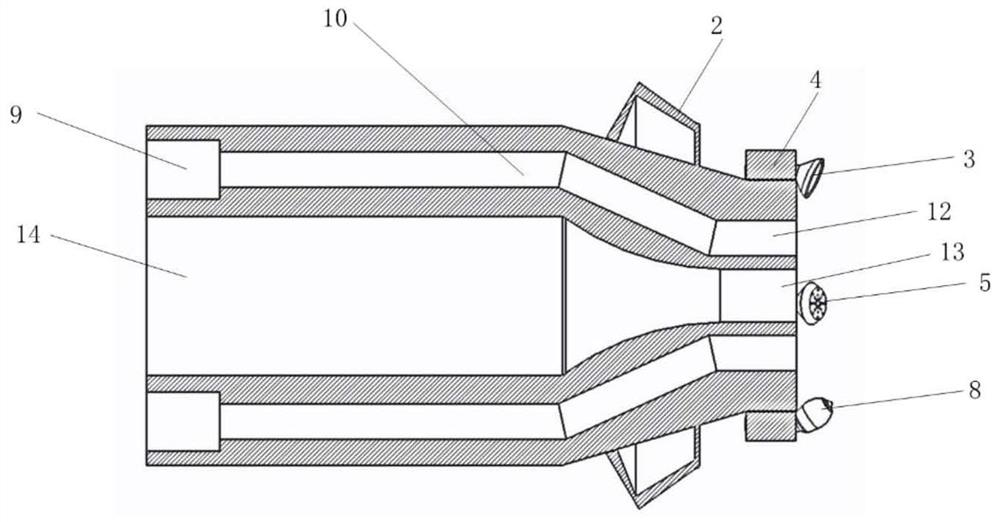

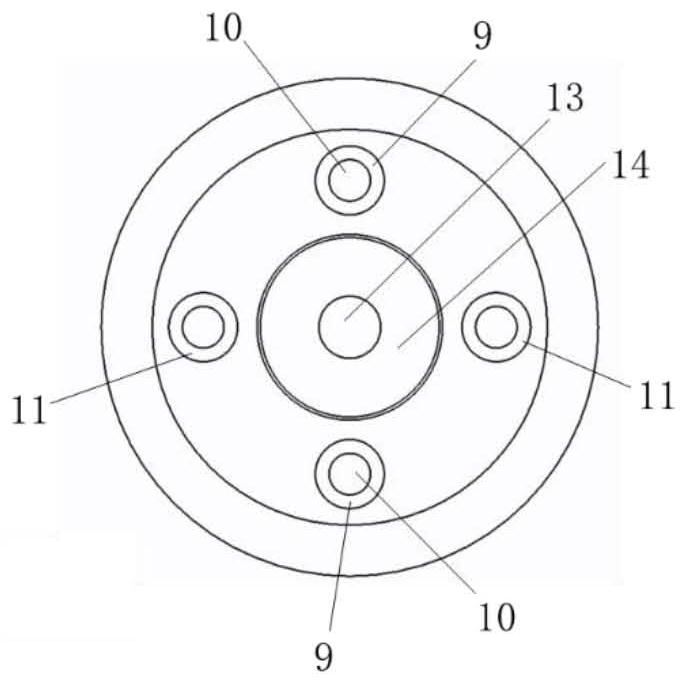

[0031] refer to figure 1 , figure 2 , image 3 and Figure 4 . The present invention provides an on-line monitoring device for combined in-situ exploitation of shale oil by laser and supercritical water, comprising an oil shale layer 1, an electric heating tool 2, a micro camera 3, a circulator 4, a lighting lamp 5, a temperature sensor 6, Pressure sensor 7 , gas sensor 8 , laser diverter 9 , energy fiber 10 , active gas 11 , laser head 12 , supercritical water gun head 13 , supercritical water generator 14 and gas nozzle 15 . The electric heating tool 2 heats t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap