Display device and fabrication method of display device

a technology of display device and fabrication method, which is applied in the direction of identification means, instruments, static indicating devices, etc., can solve the problems of increasing and the inability to form al film, so as to prevent the deterioration of the transparent conductive film and the increase of the fabrication cost of the film forming devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

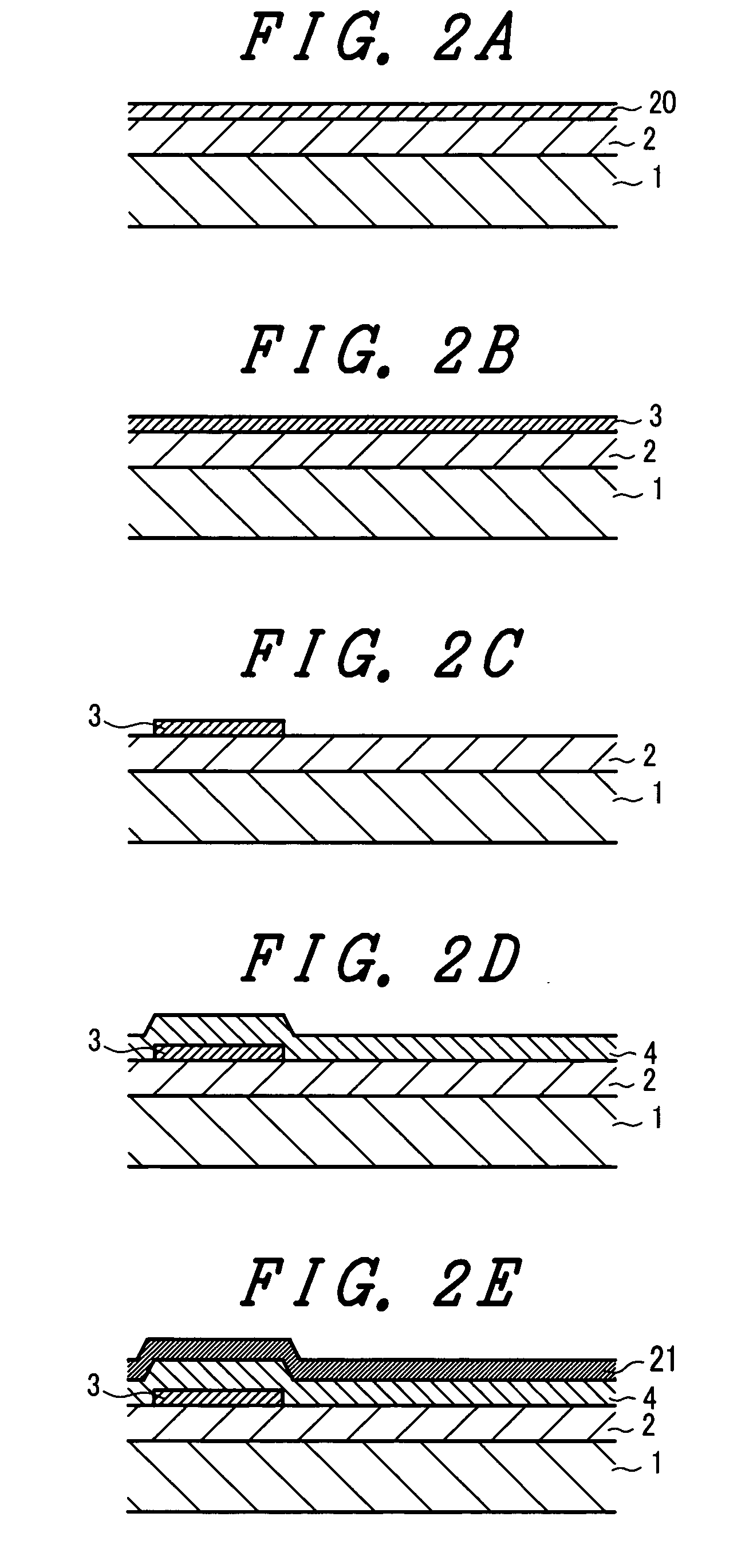

[0044] Hereinafter, an embodiment in which the present invention is applied to a reflective electrode of a partial-transmissive-type liquid crystal display device is explained in detail in conjunction with drawings.

[0045] Here, in all drawings which explain the embodiment, parts having identical functions are given equal symbols and their repeated explanation is omitted.

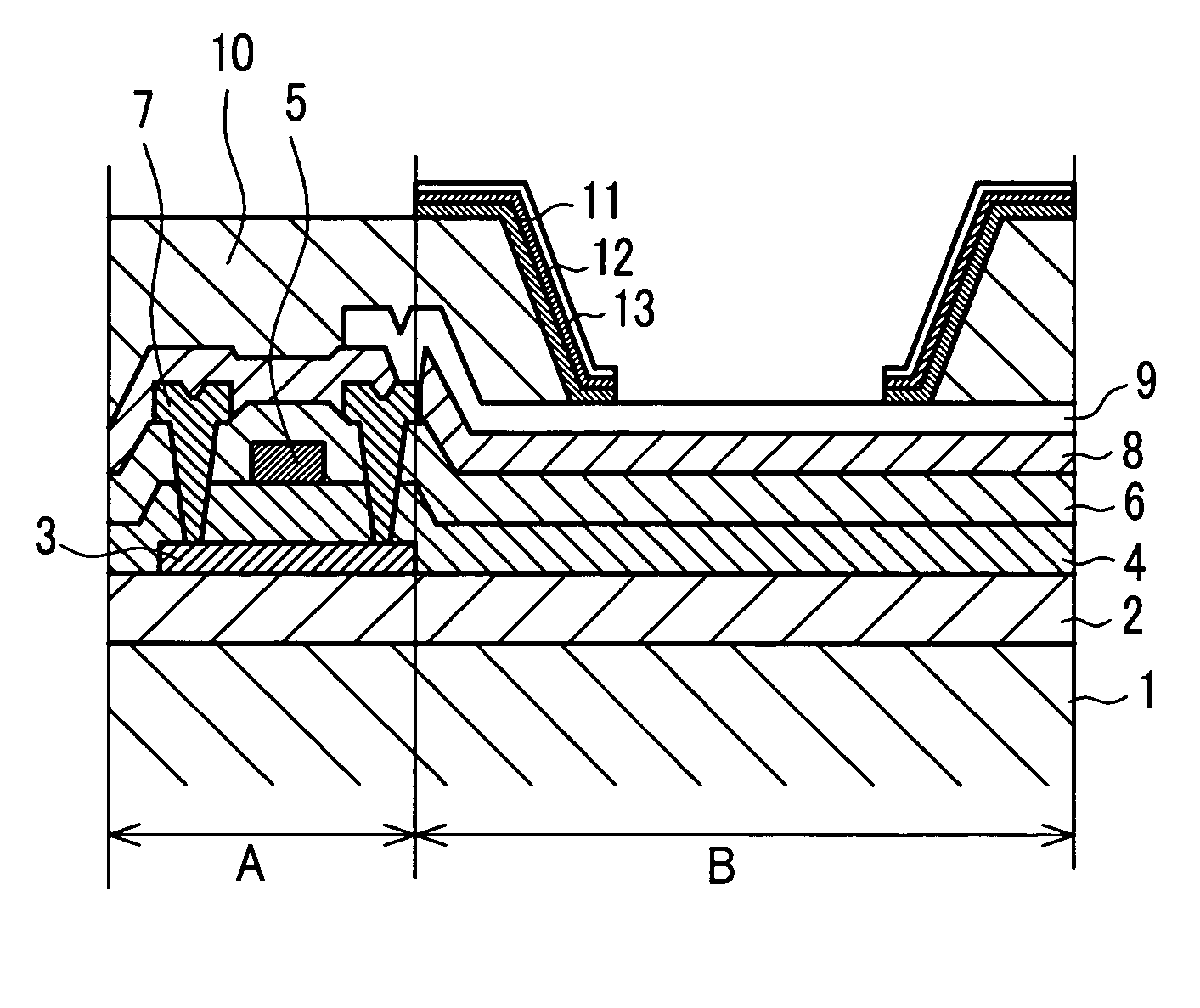

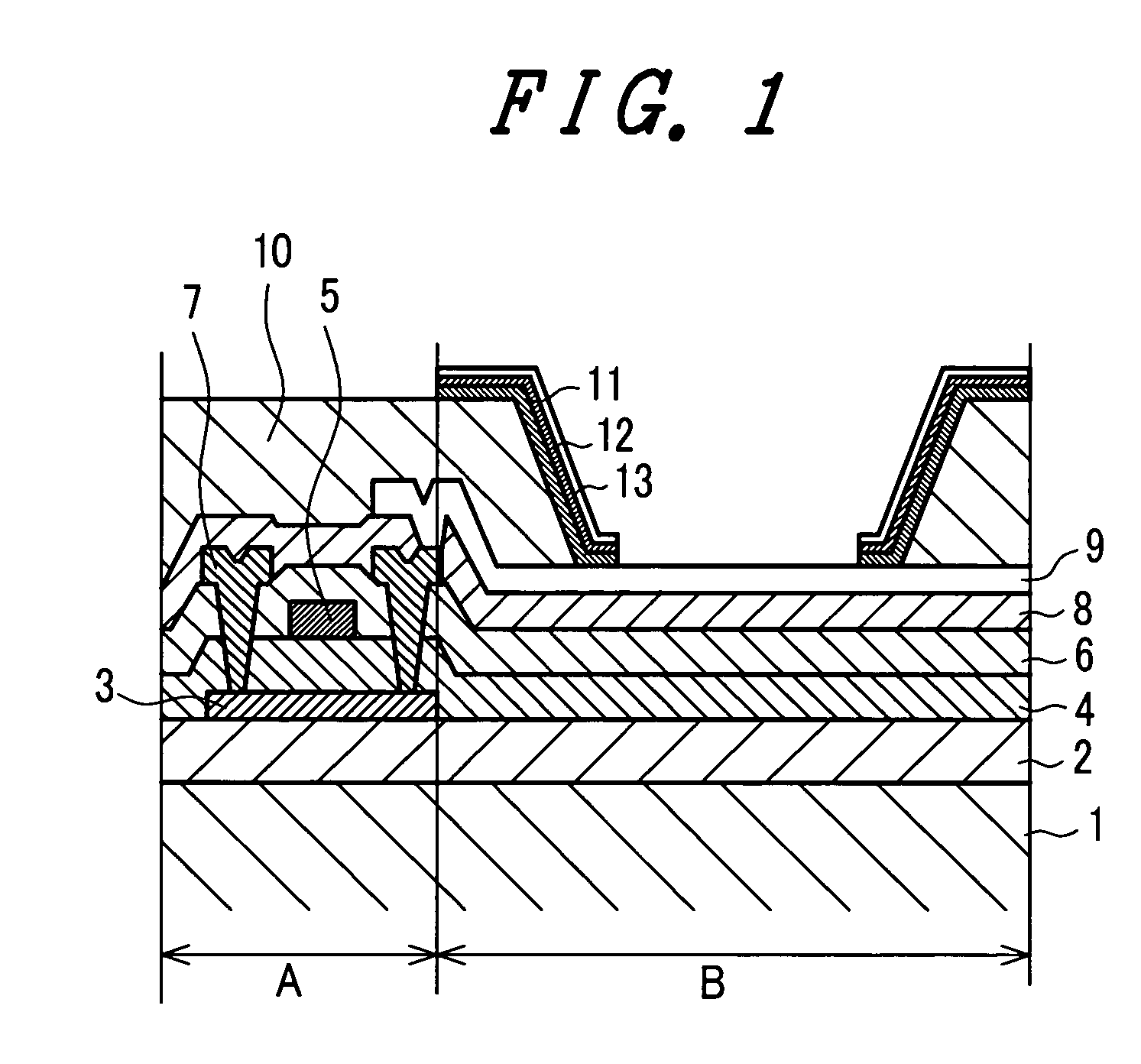

[0046]FIG. 1 is a cross-sectional view showing the cross-sectional structure of an essential part of the liquid crystal display device of the embodiment of the present invention.

[0047] In the drawing, numeral 1 indicates a glass substrate, numeral 2 indicates a background layer, numeral 3 indicates a polysilicon layer, numeral 4 indicates a gate insulation film, numeral 5 indicates a gate electrode, numerals 6, 8 indicate insulation films, numeral 7 indicates source / drain electrodes, numeral 9 indicates a transparent electrode (ITO film), numeral 10 indicates an overcoat layer (organic insulation film), numeral 11

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap