Dust scrubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1

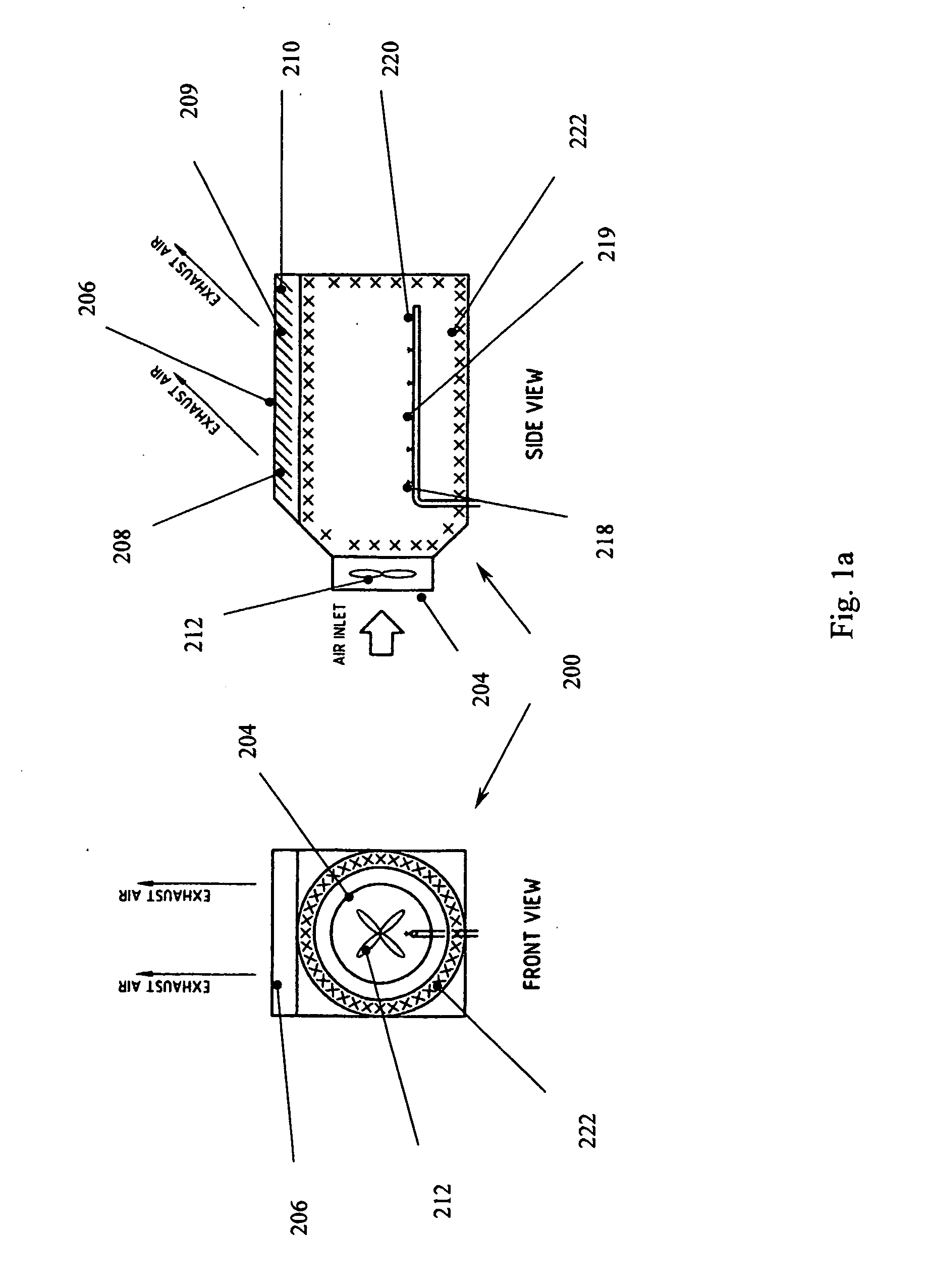

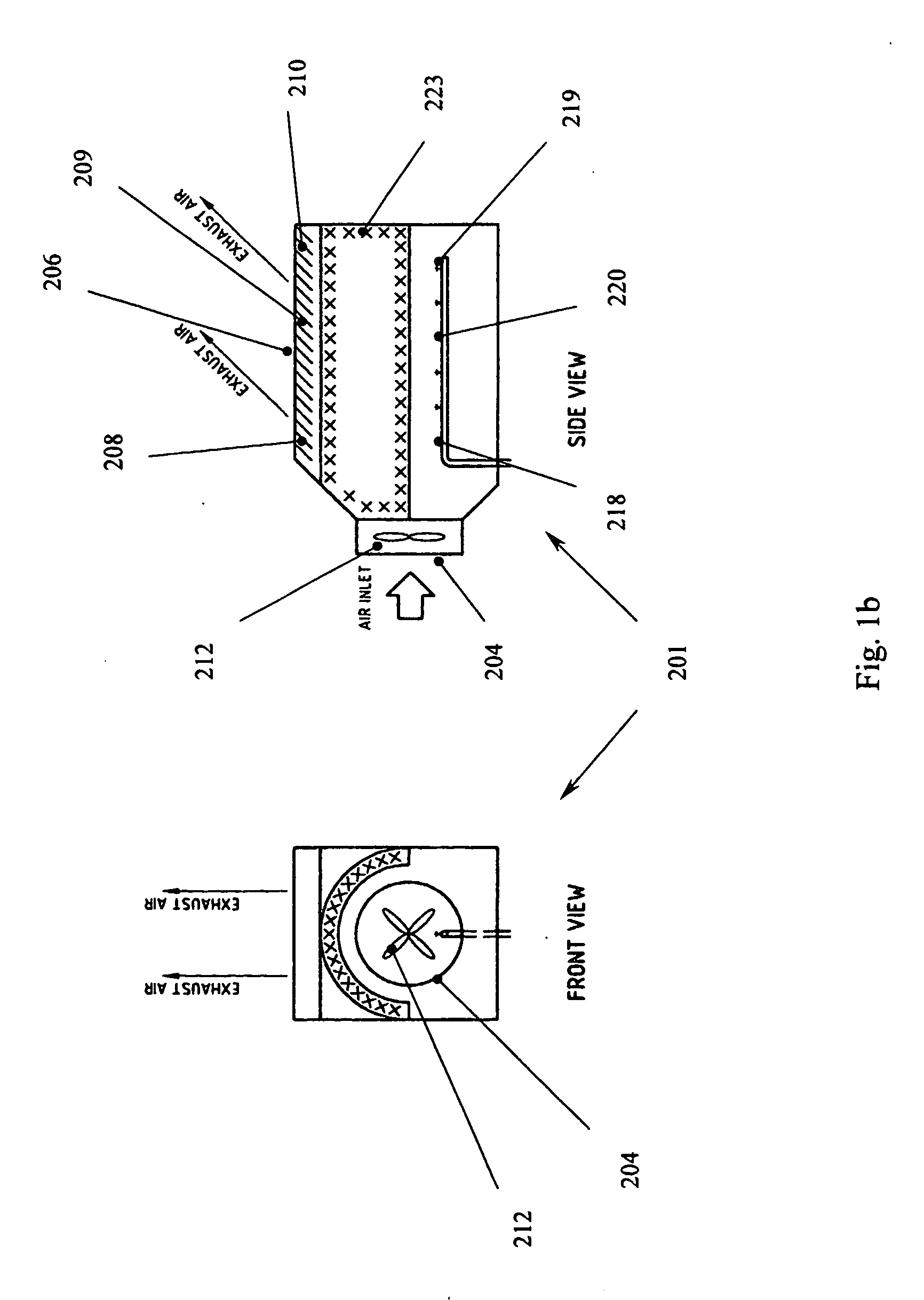

[0039]FIGS. 1a and 1b show preferred embodiments of the invention according to Example 1. The wet dust removal apparatus 200, shown in front and side views, 201 respectively comprises a rectangular housing of stainless steel. The housing has an inlet 204 and an outlet 206 wherein the outlet preferably has directional vane members 208-210 to direct the outflow of clean air in a preferred direction. The inlet houses a multi bladed fan 212 and comprises the air induction means which is powered preferably by an electrical hydraulic motor. The use of hydraulic motors is preferred in mining applications, as there is a danger of arcing or sparking with electric motors. Air containing dust particles are induced by the fan to flow into the housing via the inlet. Water mist is then sprayed into the air stream by a plurality of nozzles 218, 219, 220 comprising the water spraying means. Droplets of water capturing the dust particles are removed by the mist eliminator 222, 223. The mist e

Example

Example 2

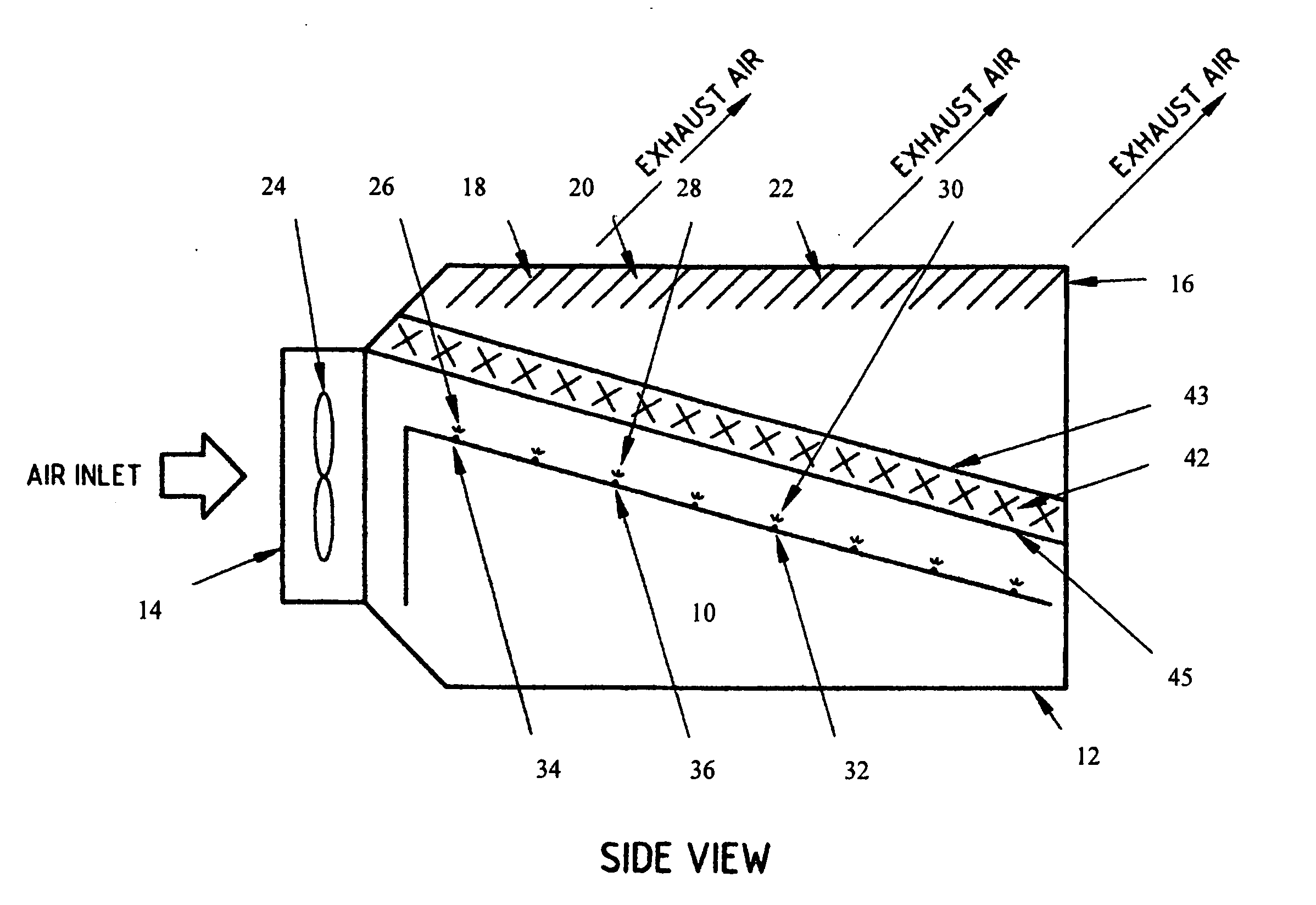

[0044]FIG. 3 shows a preferred embodiment of the second aspect of the invention according to Example 2. In this example, the wet and dry dust removal apparatus is especially adapted for use with drilling applications. The apparatus 110 is shown having a cylindrical housing 112 with an inlet 114 into which air containing large and small particulate material from around a drill from powered air induction means similar to that described in Example 1 is introduced. The cyclonic vacuum means 116 preferably comprises an electric motor driven cyclone type vessel 118 which is adapted to remove particles larger than 1.0 mm in size by centrifugal action. Smaller particles that do not conform to the physical forces required for removal by the centrifugal action pass from the cyclone type vessel into a mist 120, 122 produced by the nozzles 123, 124 of the water spraying means. The smaller particles of dust are caught by the water droplets which are then trapped by the mist eliminator 126

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap