Effective excitation, optical energy extraction and beamlet stacking in a multi-channel radial array laser system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Radial Electrode Array:

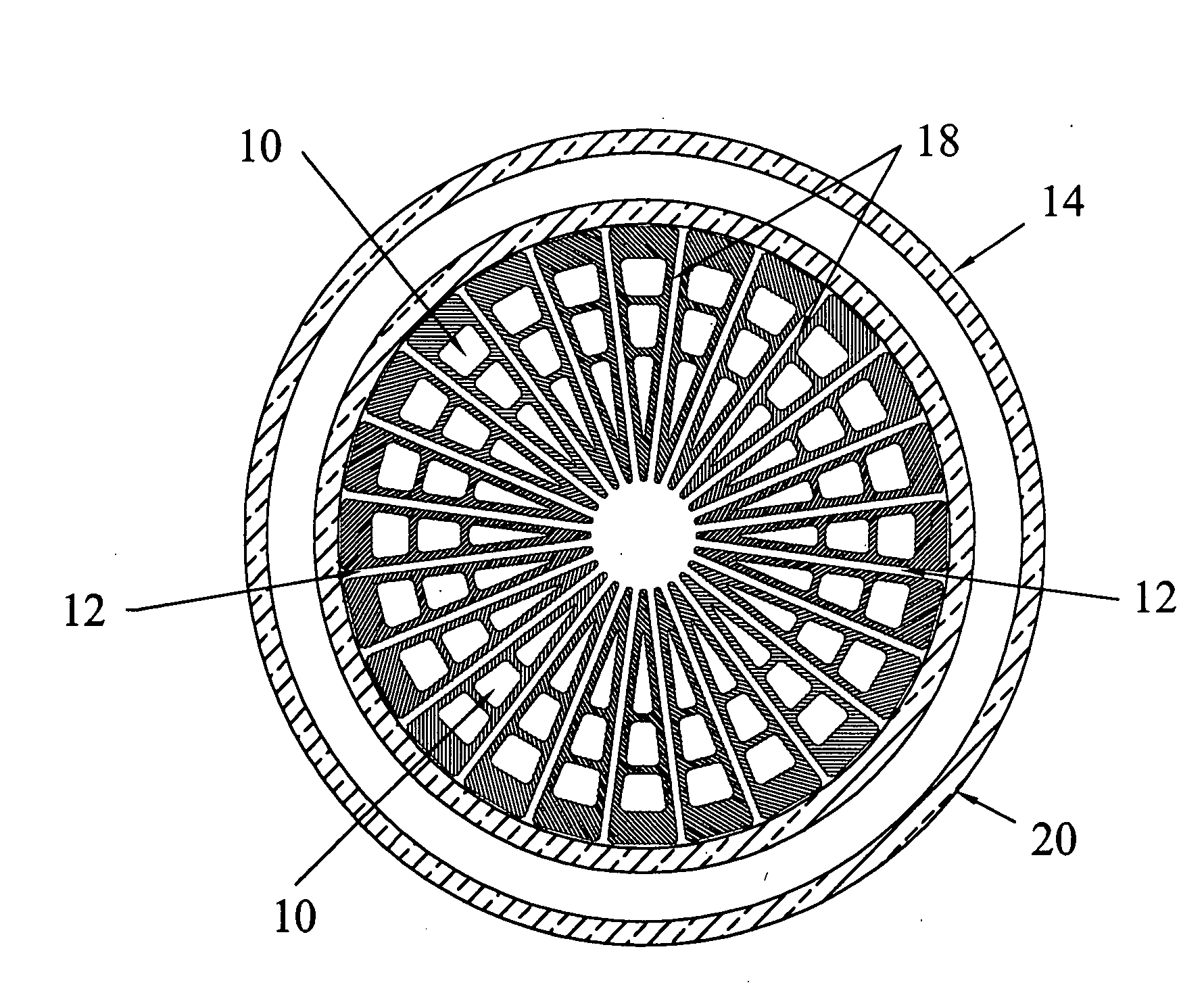

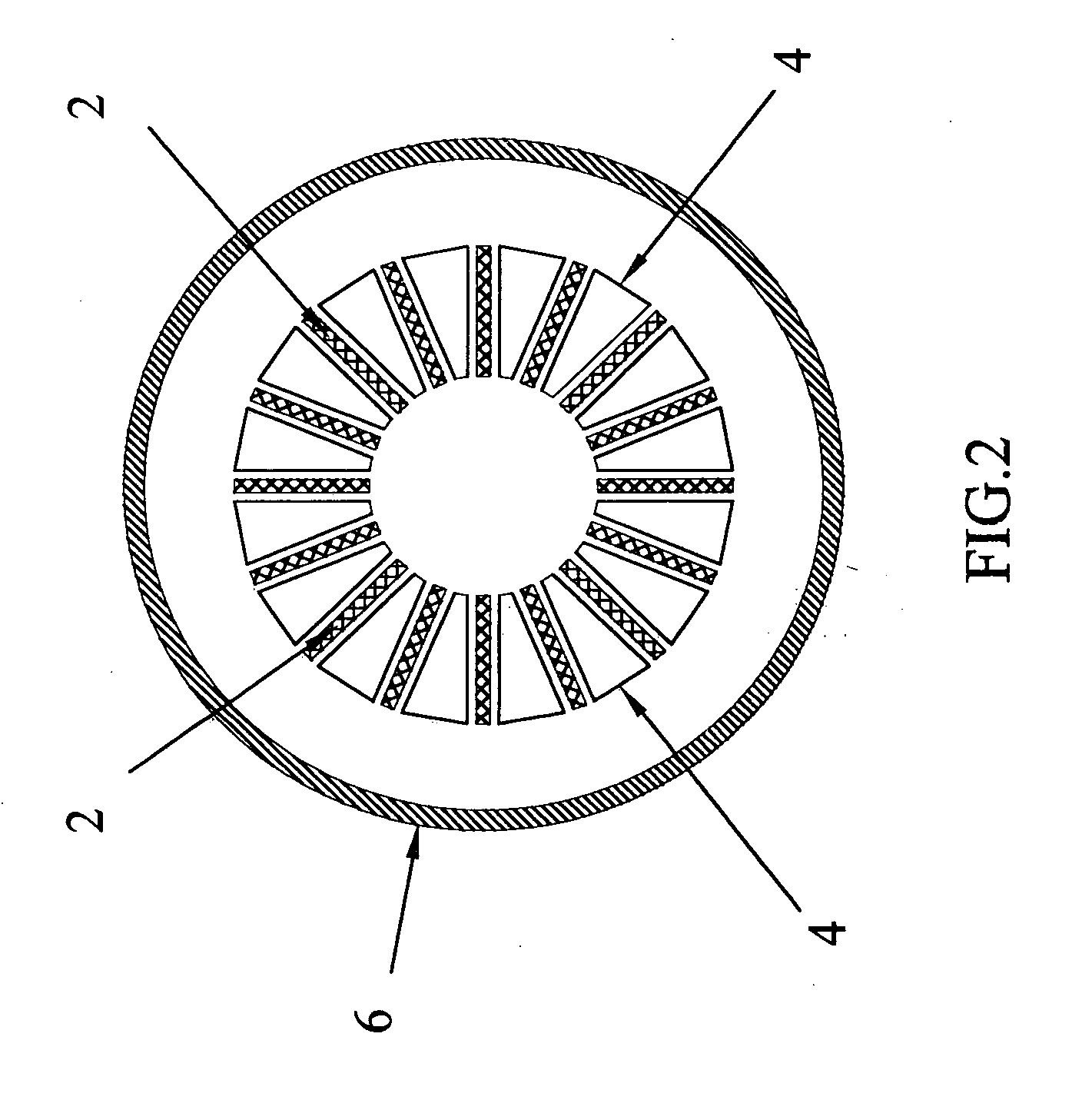

[0044] It is provided herein by way of illustration in FIGS. 3 & 4&5 typical design and constructional elements of a 5-kilowatt, RF-excited, radial-array-slab, carbon dioxide laser. As described in the previous patents listed herein, the essential aspect of the system is the electrode array, comprised of numerous, relatively long, pie-shaped metallic elements (8). The longer the electrodes the greater is the laser output power.

[0045] These electrodes are preferably made from Aluminium extrusions having many internal water-cooling passages (10). The individual electrode elements are mounted in a radial geometry featuring a very narrow-gap (12) of typically 2 mm width. Electrode mounting is afforded via several ceramic rings (14) and retaining clips (16) appropriately situated along and affixed to the back of each extruded element.

[0046] Having a small thickness but large surface area, these internal water-cooling passages (10) facilitate rapid metal-to-water h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap