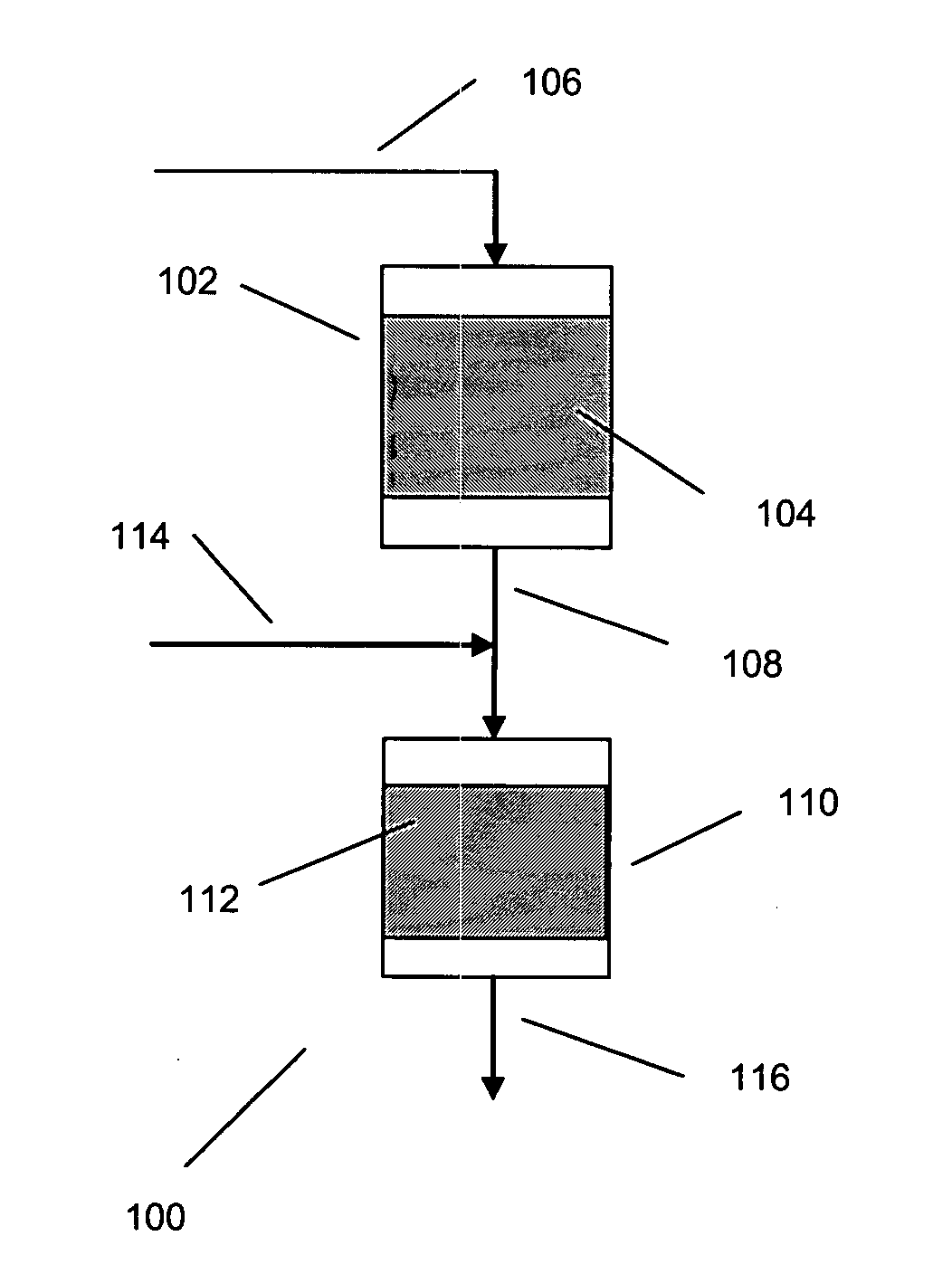

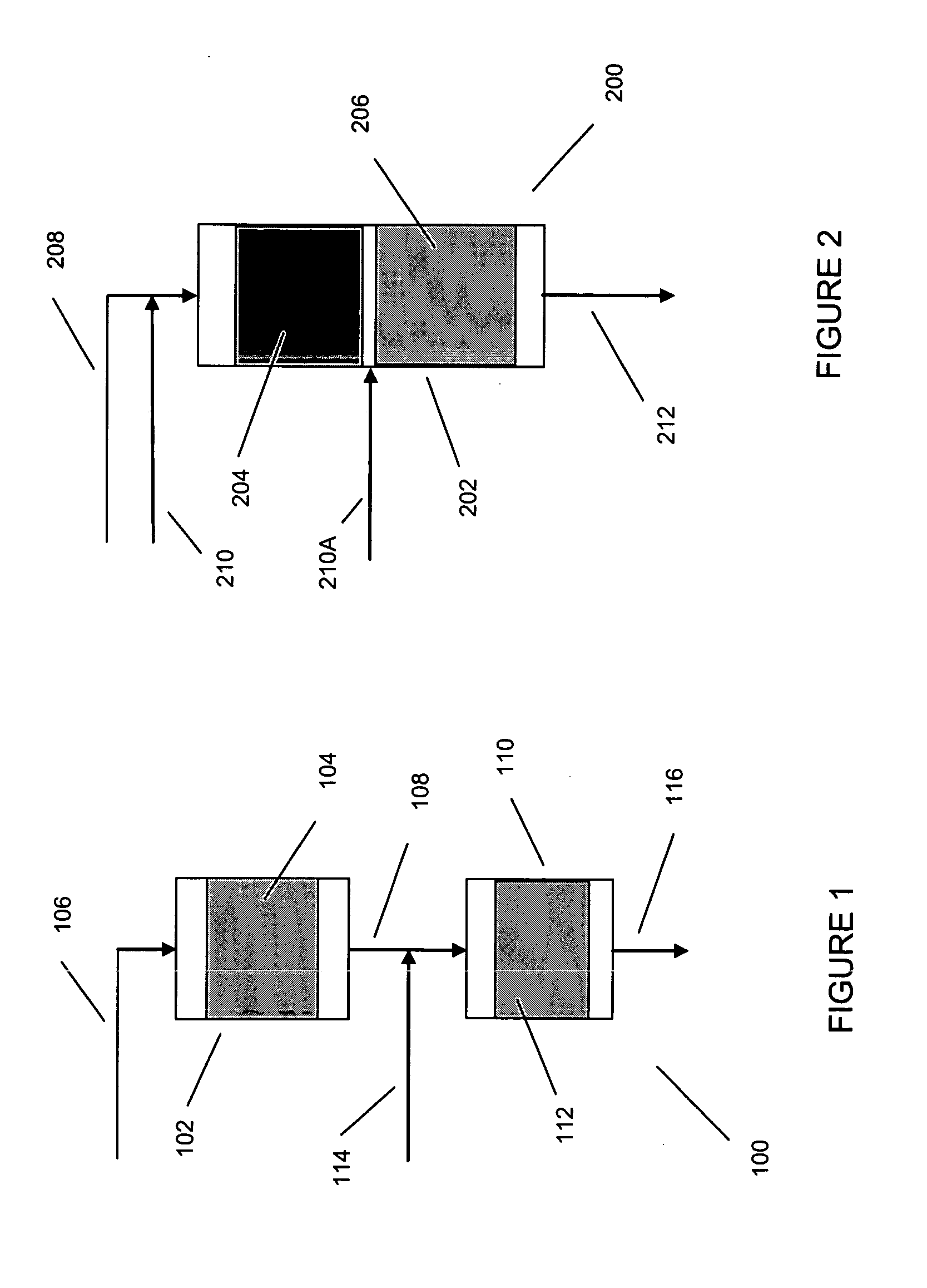

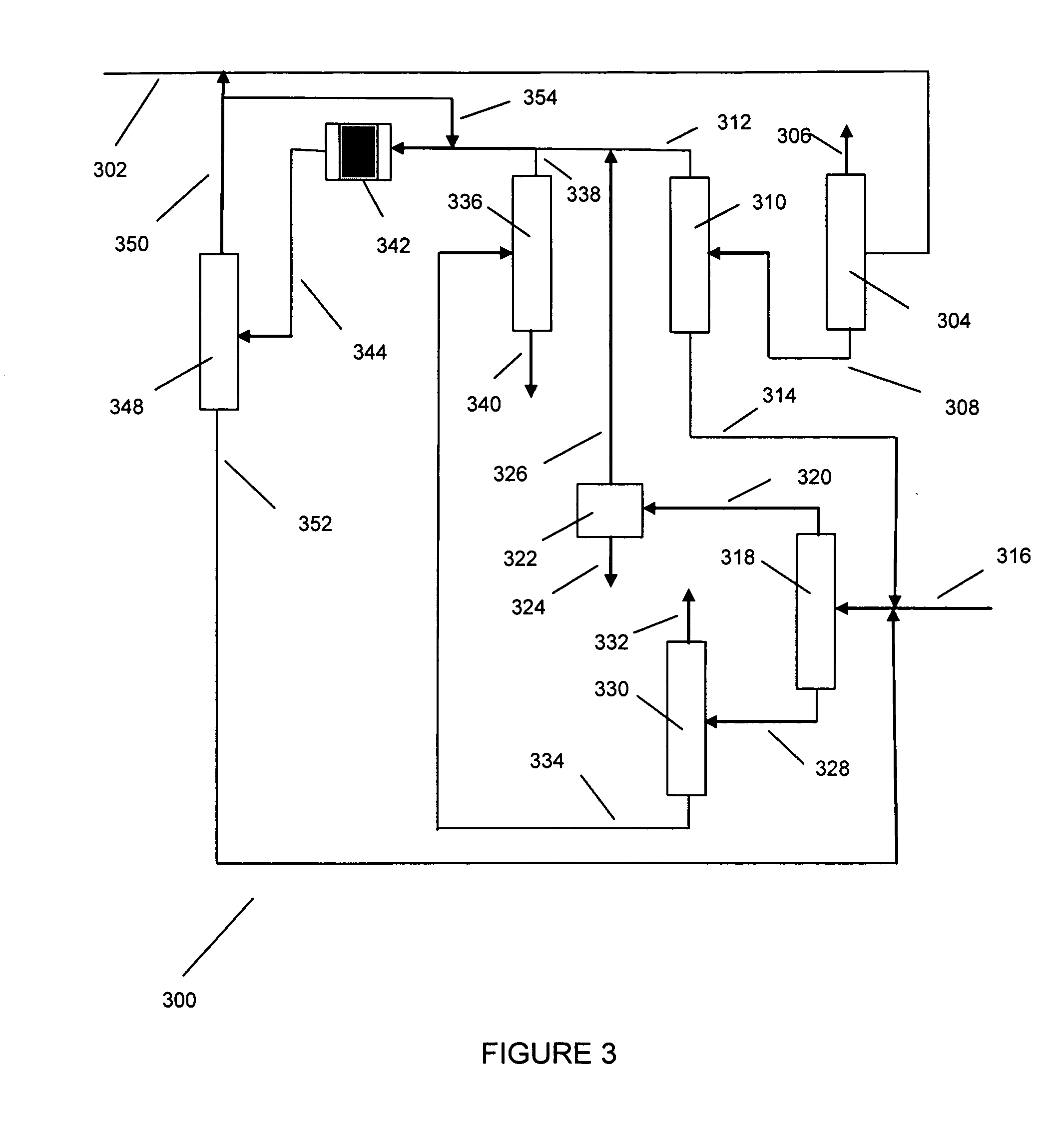

Processes for producing xylenes using isomerization and transalkylation reactions and apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Processes for the production of xylene isomer are disclosed, for instance, in Robert A. Meyers, Handbook of Petroleum Refining Processes, Second Edition, McGraw-Hill, 1997, Part 2.

[0052] In general, the feed stream for aromatics isomerization is typically a C8 aromatics stream from which one or more xylenes have been removed as product. The C8 aromatics stream from which one or more xylenes are removed is typically derived from xylene containing recycle and fresh C8 aromatics feed. Usually the fresh C8 aromatics feed is obtained from processes, such as catalytic reforming and / or extraction, for the production and recovery of aromatics from other hydrocarbons. Hence, fresh alkylaromatic for use in the present invention may be found in appropriate fractions from various refinery petroleum streams, e.g., as individual components or as certain boiling-range fractions obtained by the selective fractionation and distillation of catalytically cracked or reformed hydrocarbons. Concen

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap