Nitride based semiconductor laser device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

2. Second Embodiment

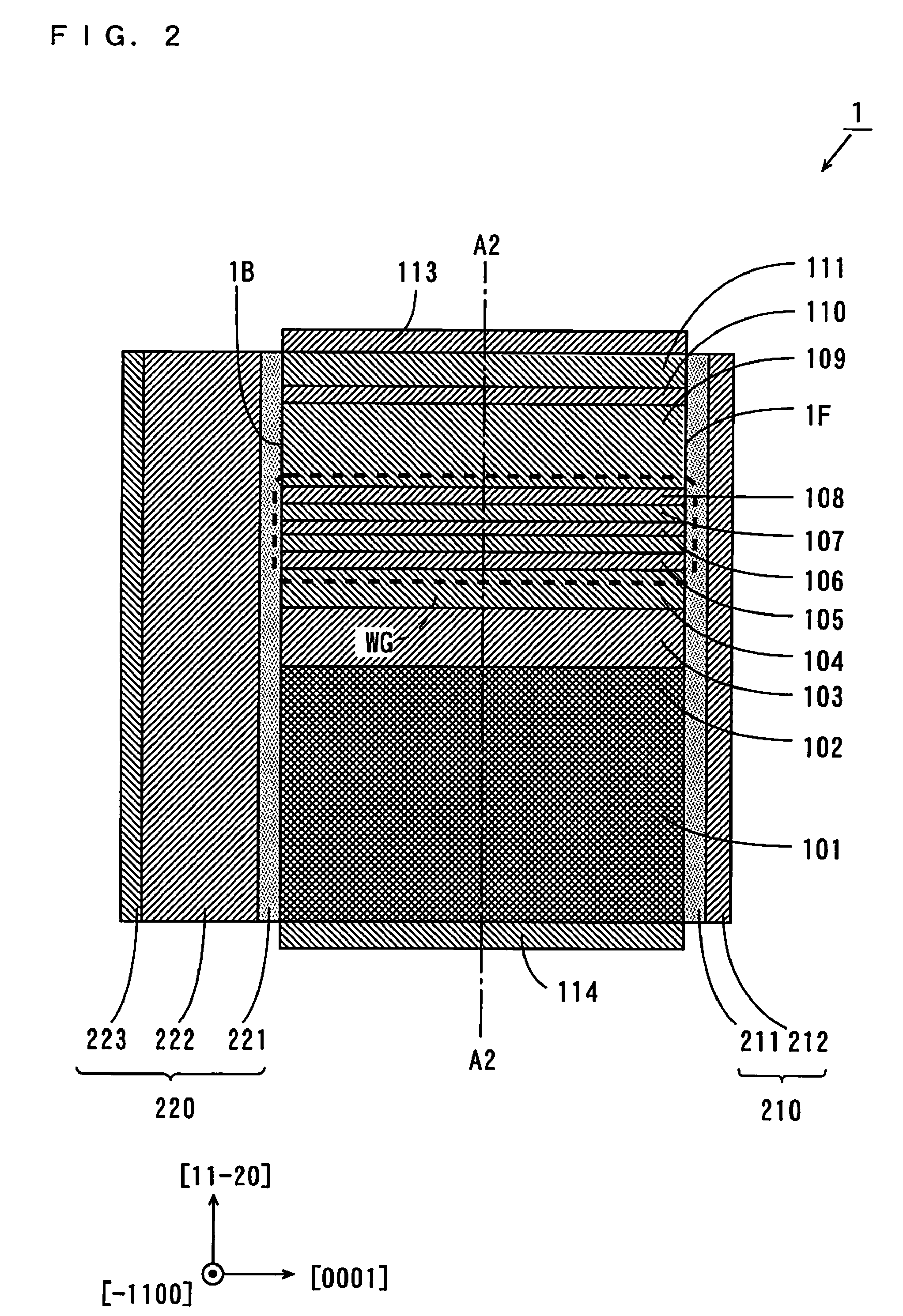

[0090]As to a nitride based semiconductor laser device according to a second embodiment, the difference from the nitride based semiconductor laser device 1 according to the first embodiment will be described.

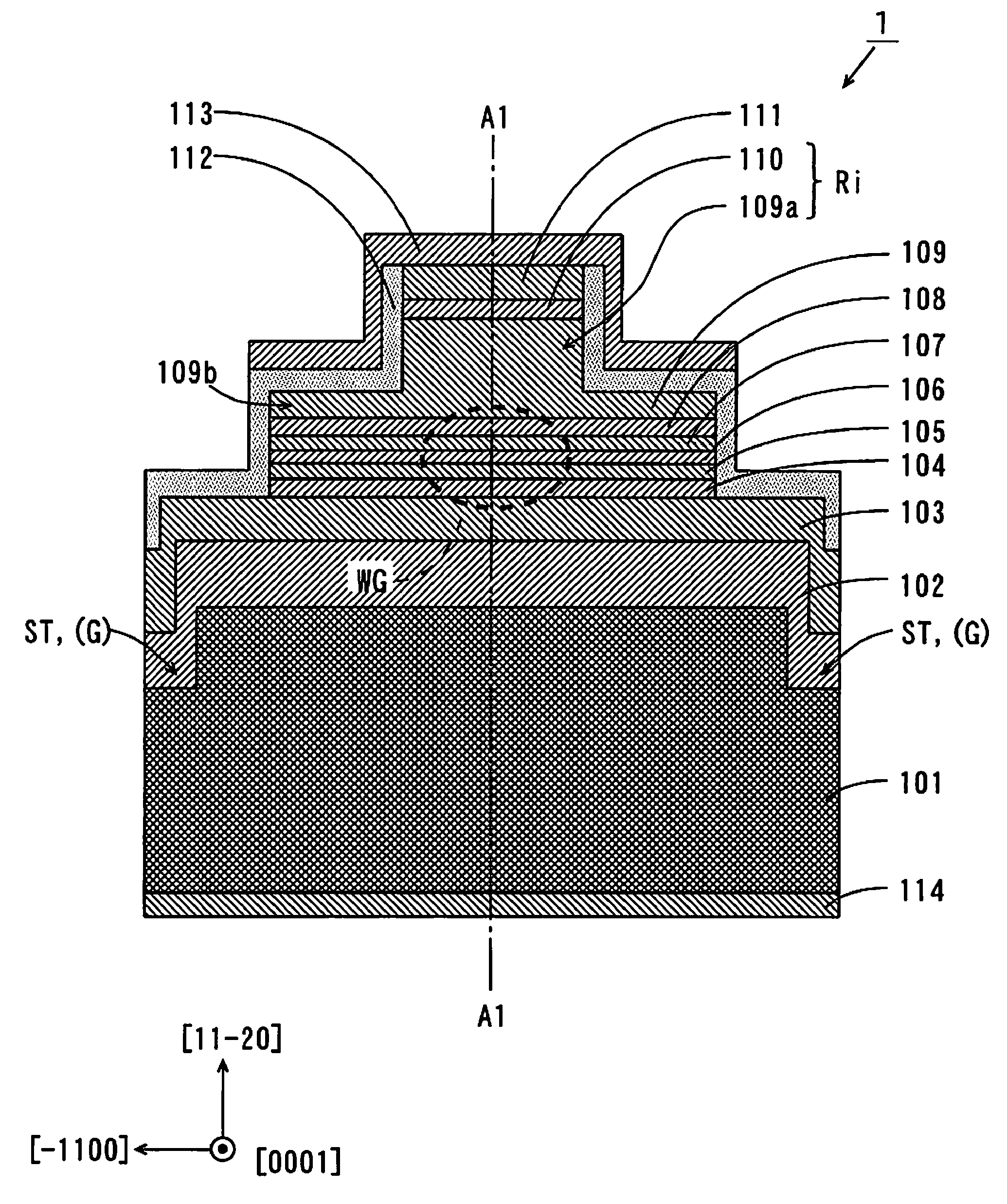

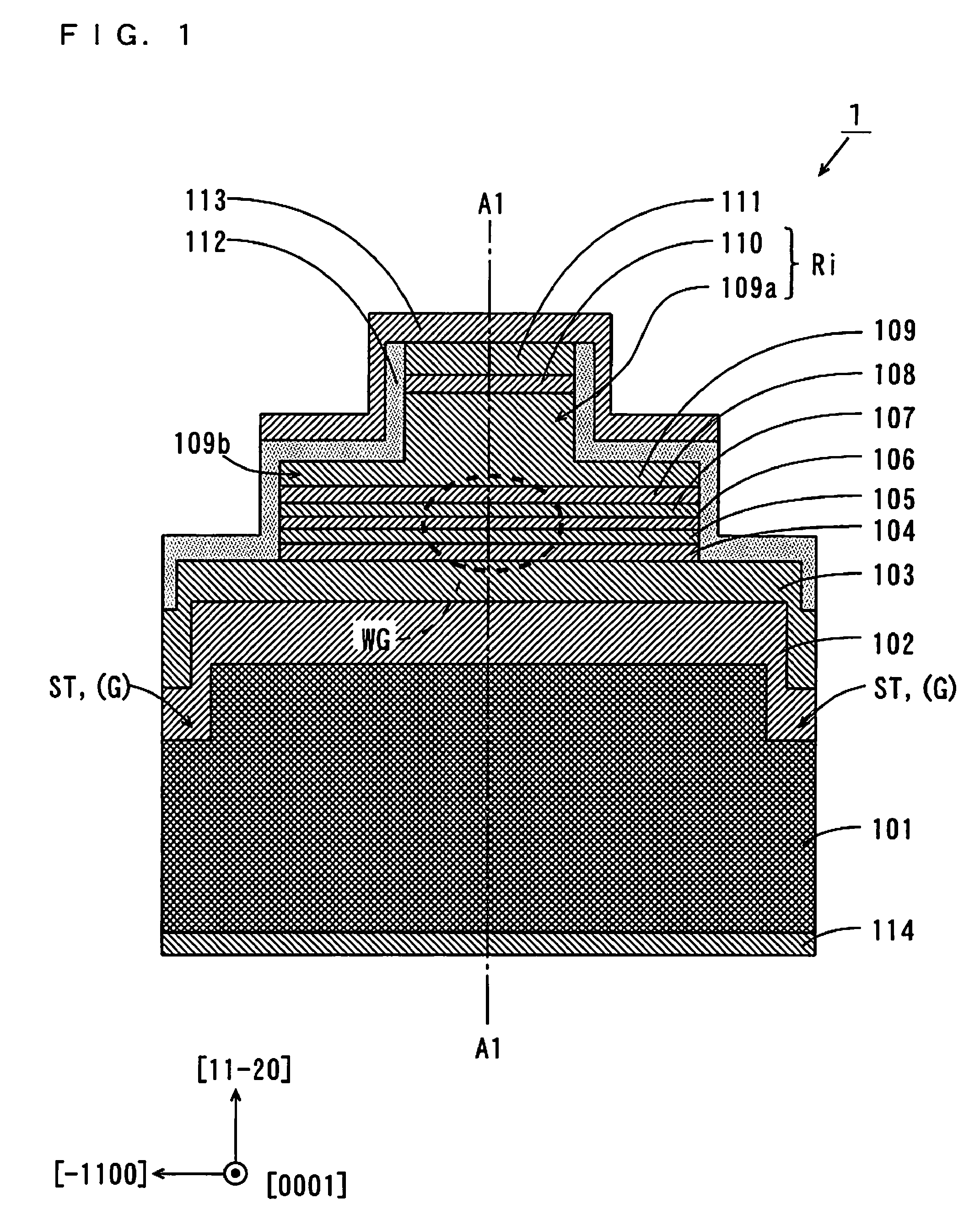

[0091]FIG. 5 is a vertical sectional view of the nitride based semiconductor laser device according to the second embodiment. In FIG. 5, a vertical section of the nitride based semiconductor laser device 1 along a [0001] direction is shown, similarly to the vertical section shown in FIG. 2 in the first embodiment. A vertical section taken along a line A2-A2 shown in FIG. 5 is the same as the vertical section of the nitride based semiconductor laser device 1 shown in FIG. 1.

[0092]A first dielectric multilayer film 210 is formed on a light emission facet 1F of the nitride based semiconductor laser device 1. The first dielectric multilayer film 210 has a structure in which an AlOXNY film (X211a and an Al2O3 film 212a are laminated in this order. Here, the refractiv

Example

3. Third Embodiment

[0096]As to a nitride based semiconductor laser device according to a third embodiment, the difference from the nitride based semiconductor laser device 1 according to the first embodiment will be described.

[0097]FIG. 6 is a vertical sectional view of the nitride based semiconductor laser device according to the third embodiment. In FIG. 6, a vertical section of the nitride based semiconductor laser device 1 along a [0001] direction is shown, similarly to the vertical section shown in FIG. 2 in the first embodiment. A vertical section taken along a line A2-A2 shown in FIG. 6 is the same as the vertical section of the nitride based semiconductor laser device 1 shown in FIG. 1.

[0098]A first dielectric multilayer film 210 is formed on a light emission facet 1F of the nitride based semiconductor laser device 1. The first dielectric multilayer film 210 has a structure in which an AlN film 211b, an AlOXNY film (X212b, and an Al2O3film 213b are laminated in this order. The

Example

4. Fourth Embodiment

[0102]As to a nitride based semiconductor laser device according to a fourth embodiment, the difference from the nitride based semiconductor laser device 1 according to the first embodiment will be described.

[0103]FIG. 7 is a vertical sectional view of the nitride based semiconductor laser device according to the fourth embodiment. In FIG. 7, a vertical section of the nitride based semiconductor laser device 1 along a [0001] direction is shown, similarly to the vertical section shown in FIG. 2 in the first embodiment. A vertical section taken along a line A2-A2 shown in FIG. 7 is the same as the vertical section of the nitride based semiconductor laser device 1 shown in FIG. 1.

[0104]A first dielectric multilayer film 210 is formed on a light emission facet 1F of the nitride based semiconductor laser device 1. The first dielectric multilayer film 210 has a structure in which an AlOXNY film (X211c, an AlOXNY film (X>Y) 212c, and an Al2O3 film 213c are laminated in thi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap