Single Output H-Bridge Drive

a single output, drive technology, applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problem of rotating the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

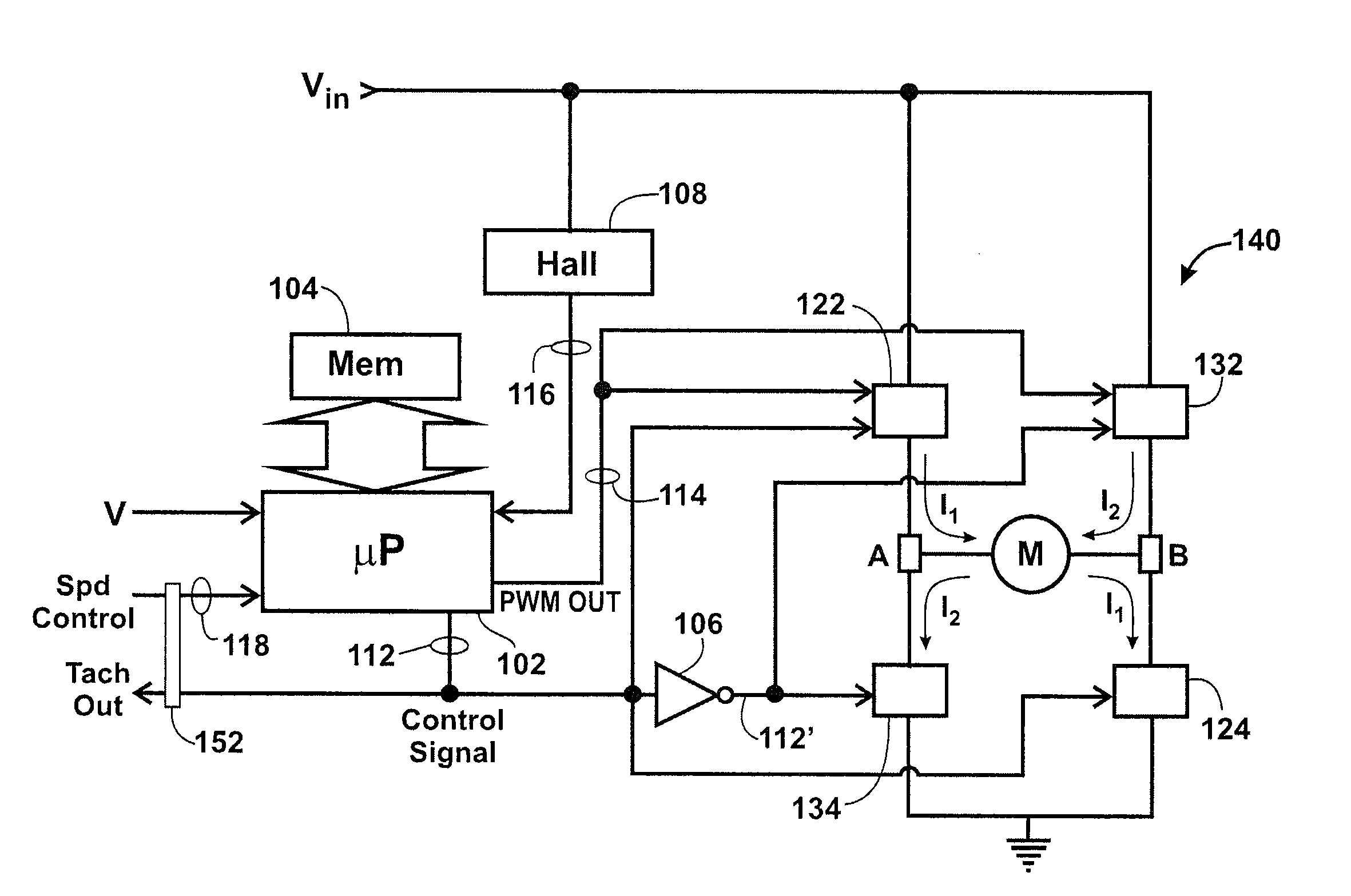

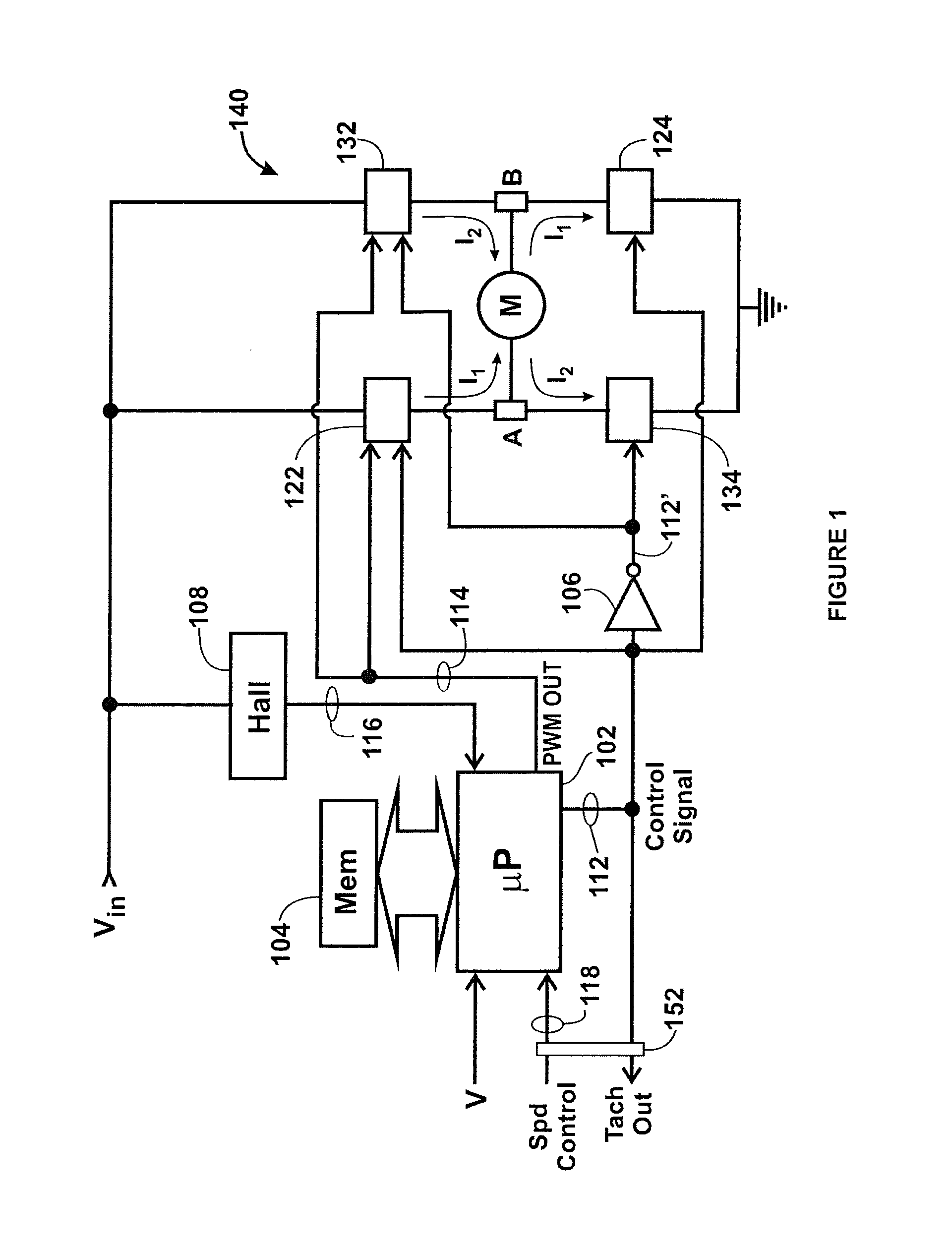

[0011]FIG. 1 illustrates a generalized block diagram of components of a drive circuit according to the present invention for producing and delivering the drive current to the winding of a bipolar brushless DC motor M.

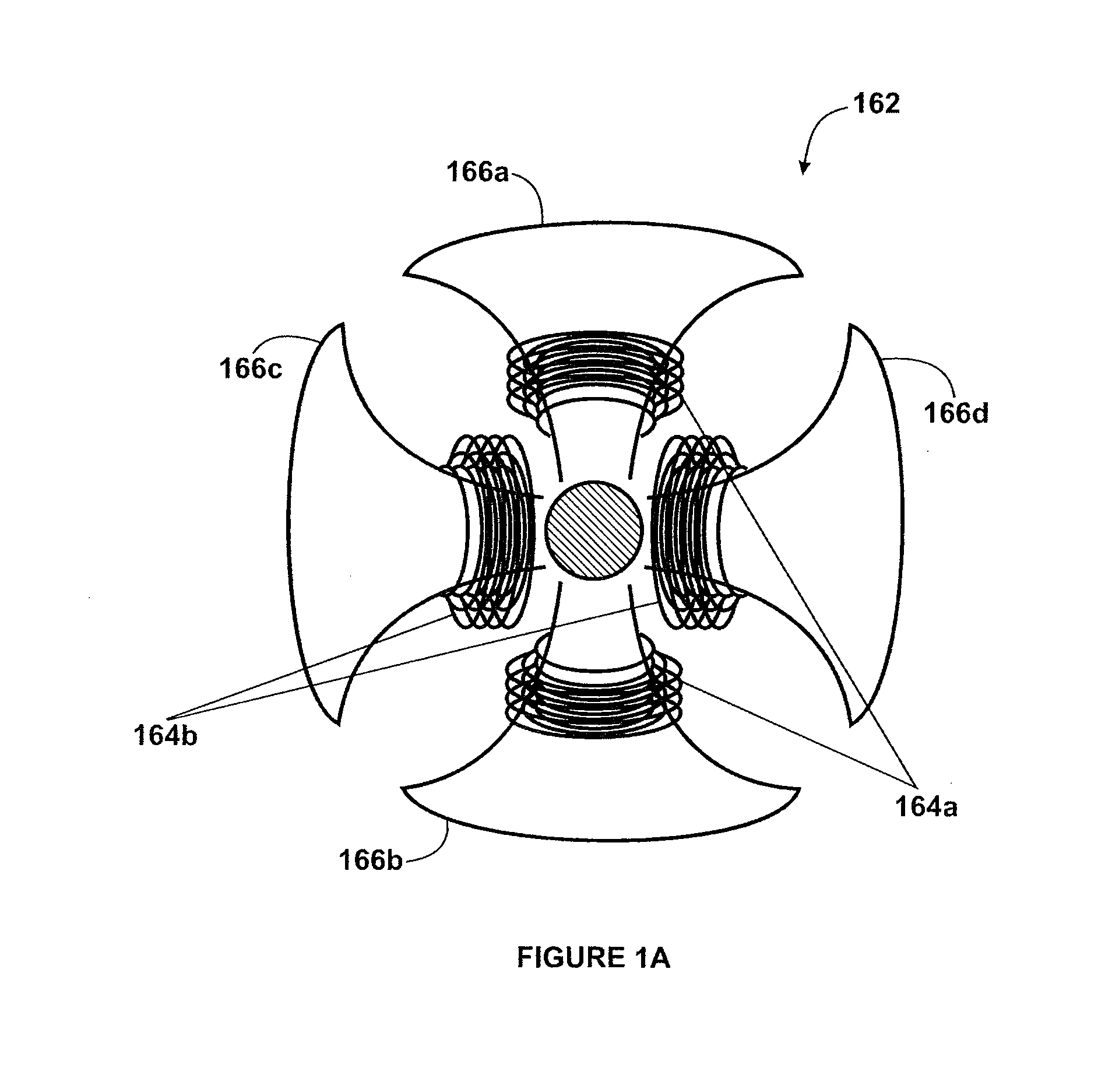

[0012]FIG. 1A shows the stator winding 162 (4 tooth, 4 slot) for a bipolar motor. The particular bipolar configuration shown in the figure uses a four slot stator 162 with stator windings on each of the four teeth 166a-166d. It will be appreciated that the present invention can be used with other slot configurations.

[0013]In the stator winding 162 shown in FIG. 1A, commutation involves driving current through pairs of the stator windings in synchrony with the rotor. There is a single winding that wraps around all four stator teeth 166a-166d, but they are wound in alternating clockwise and counter-clockwise orientations. Thus, in a bipolar motor, the windings 164a, 164b shown in FIG. 1A represent two segments of a single winding. Thus, if segment 164a is wound around both t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap