Burner for a heater with improved fuel supply, improved heat shield and improved baffle plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In the following description of preferred embodiments of the invention, the same reference numbers label the same or comparable components.

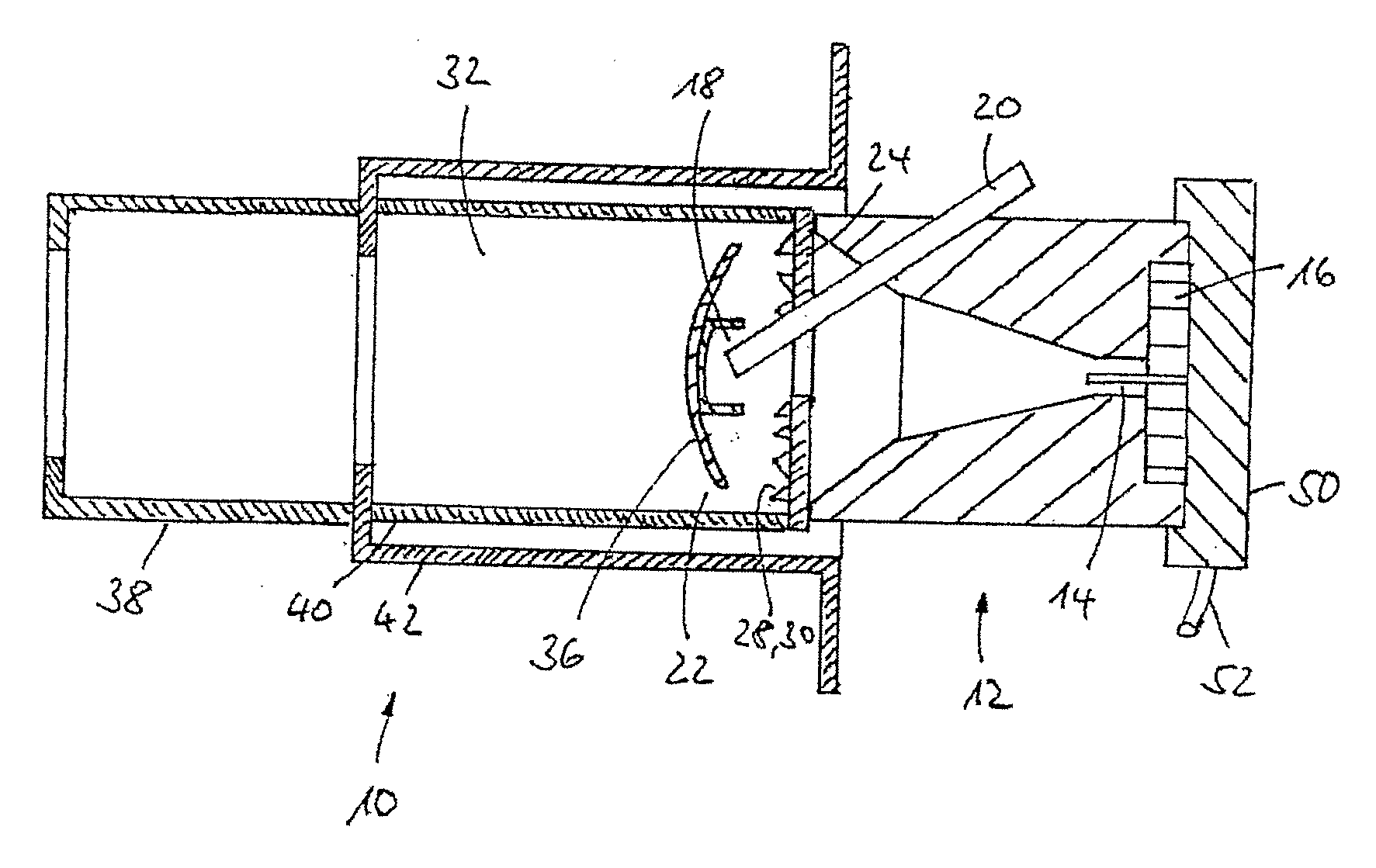

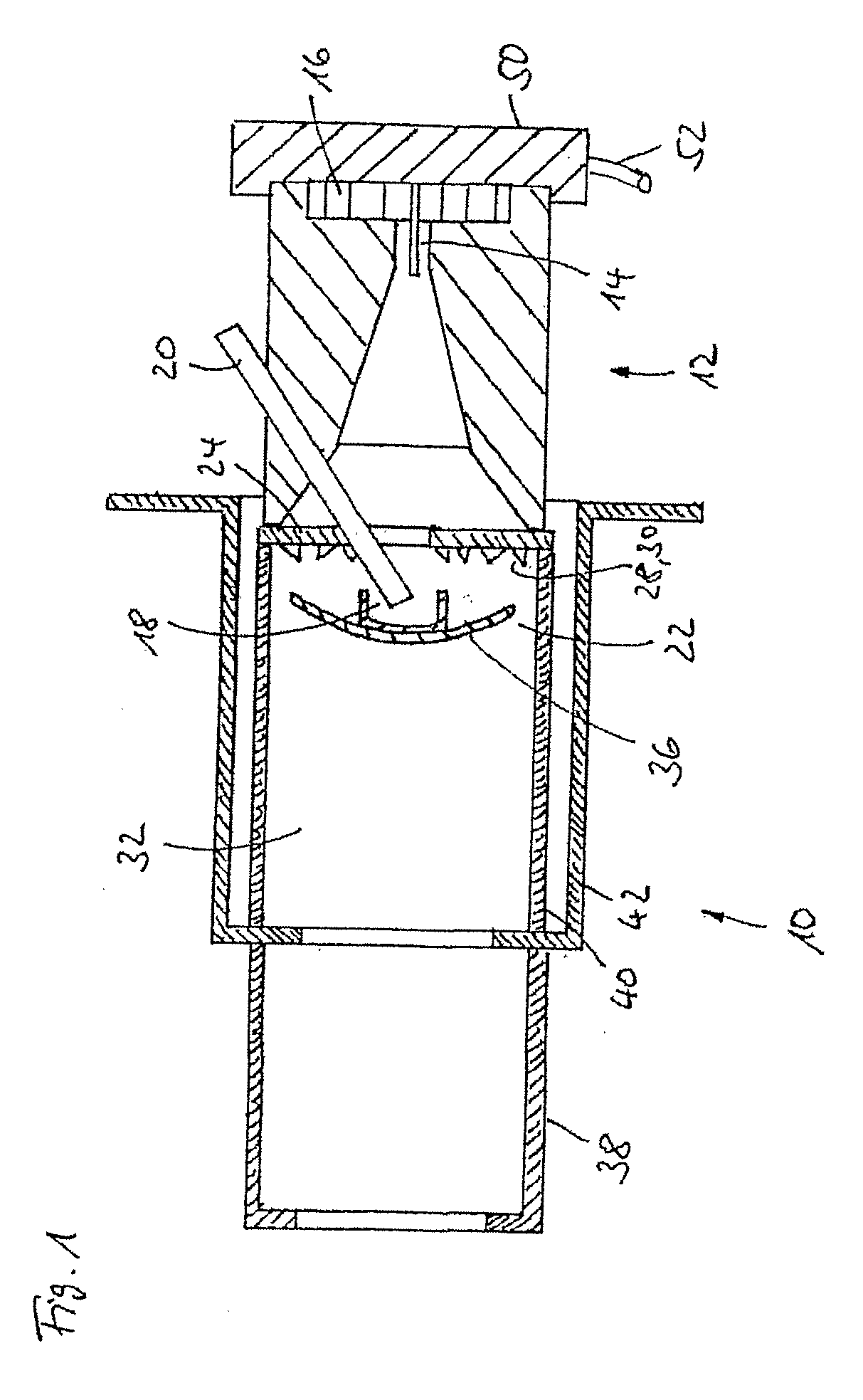

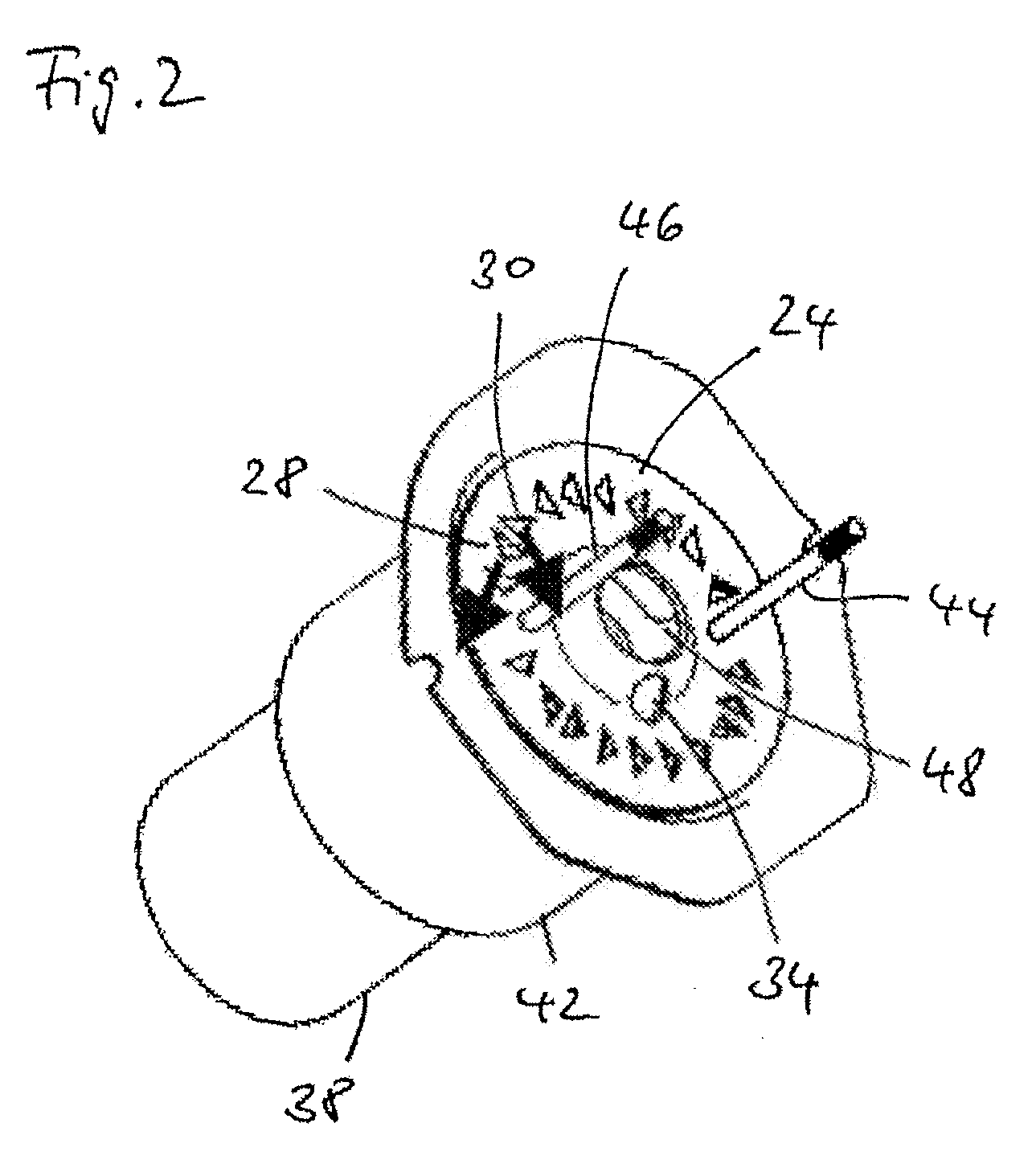

[0029]FIG. 1 shows a sectional view of a burner 10 of the invention. The burner 10 has a nozzle 12 which is securely joined to the heat shield 24. The heat shield 24, together with a burner pipe 40 which is connected to the heat shield 24, defines a combustion chamber 22. The combustion chamber pipe 40 is surrounded by an outer pipe 42 which forms the burner flange. A flame tube 38 is attached to this outer pipe 42. The connections between the heat shield 24 and the combustion chamber pipe 40 or between the combustion chamber pipe 40, the outer pipe 42 and the flame tube 38 are generally welded connections. On the fuel nozzle 12, there is a fuel supply 50 which has a metal pipe 52 for supply of fuel and a fuel needle 14 for injection of fuel into the combustion chamber 22. Furthermore, in the region of the fuel nozzle 16, there are channels fo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap