Fabrication Process to Connect Branch Air Ducts to Main Air Ducts and the Fabricated Ventilating Ducts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1

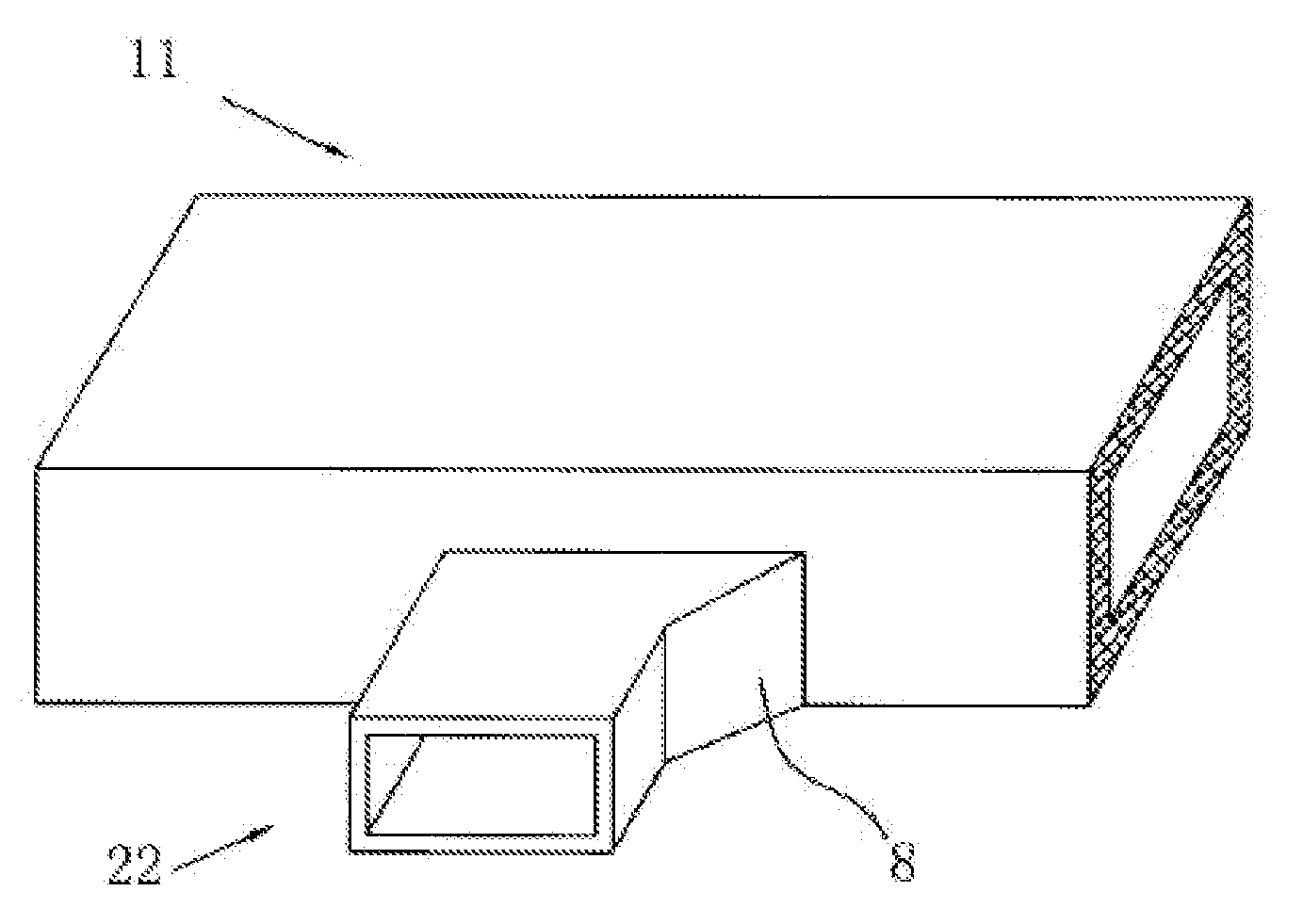

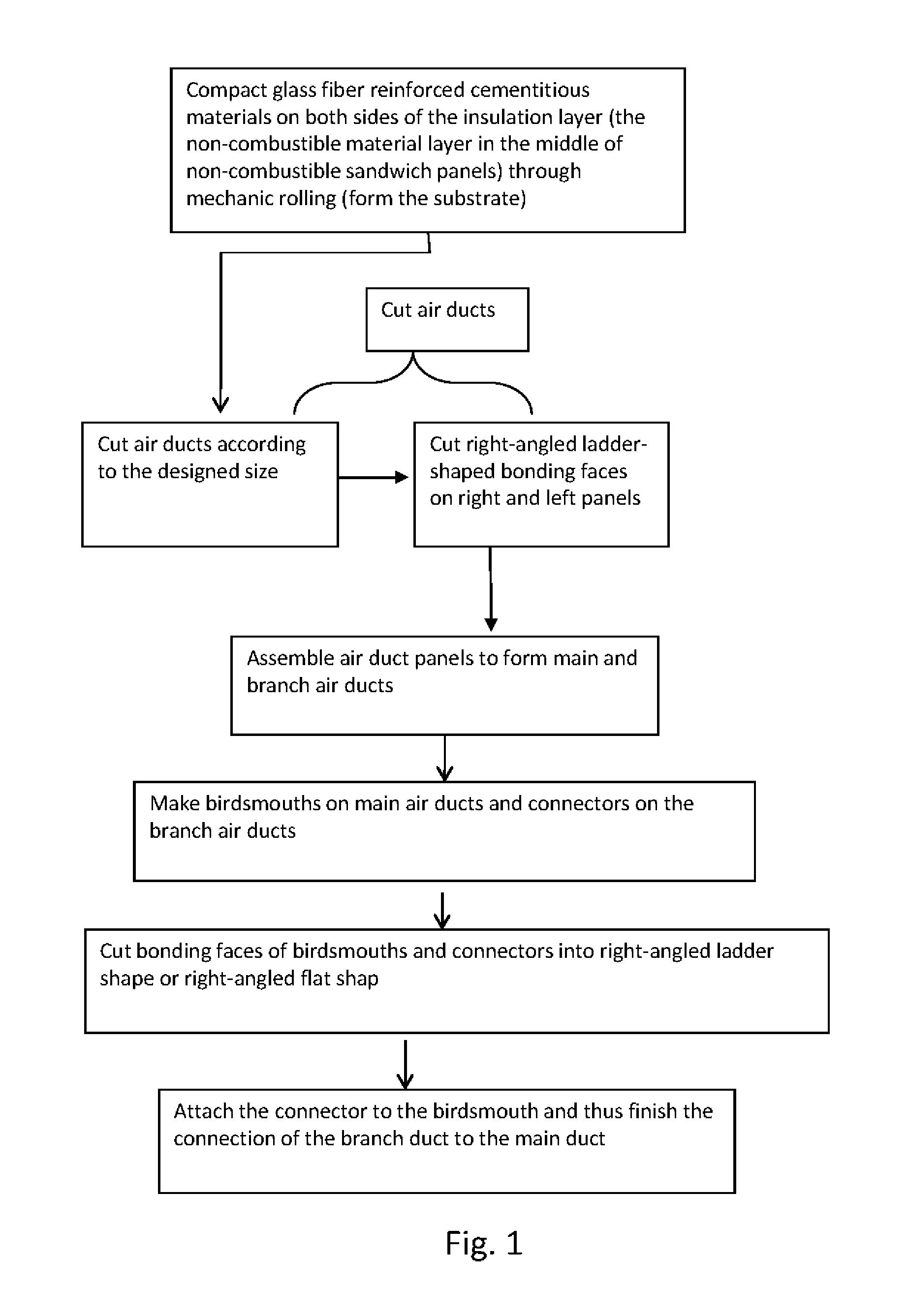

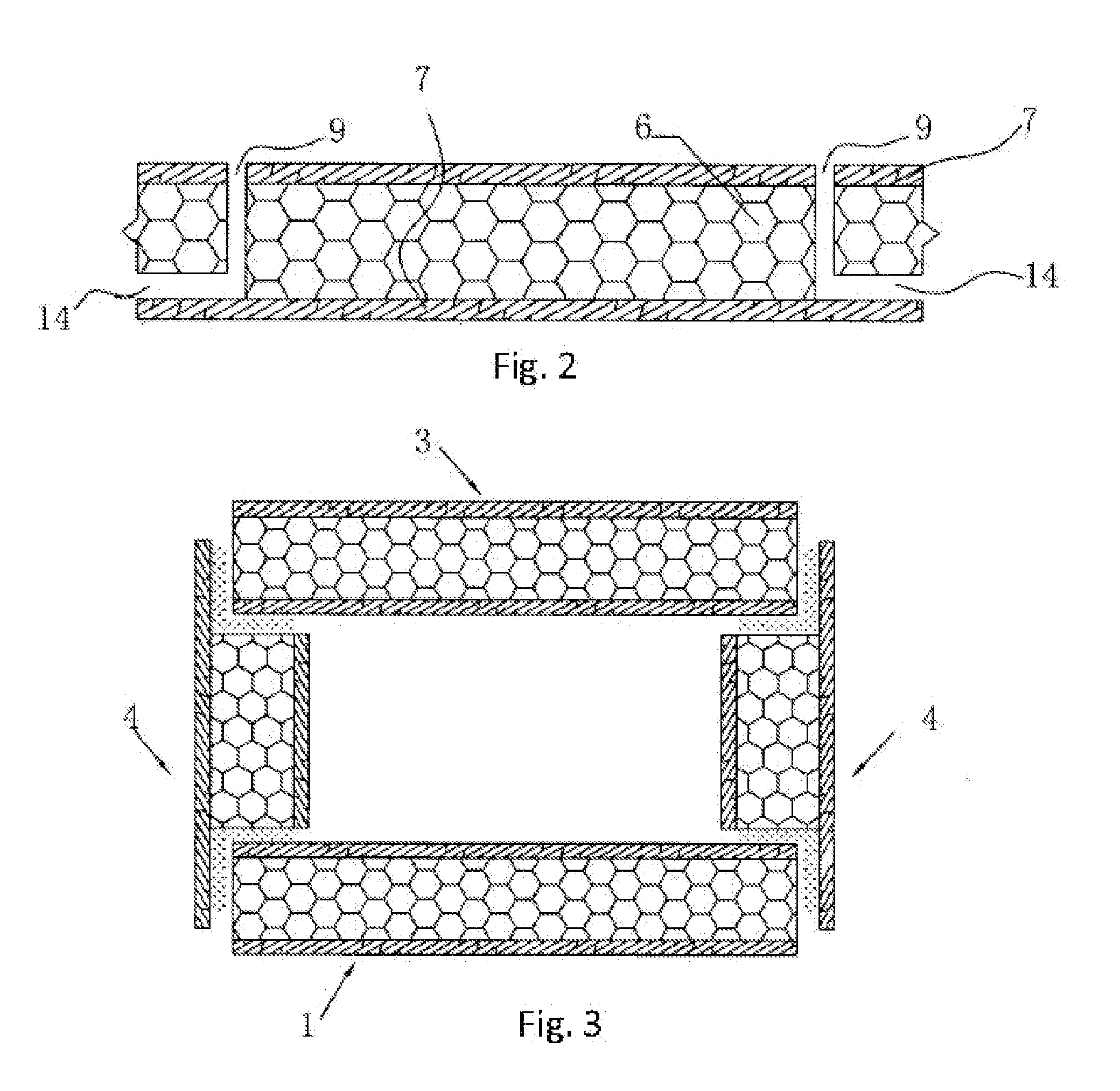

[0036]A fabrication process to connect branch ventilating ducts to main ventilating ducts, as shown in FIG. 1 (The steps within the broken lien frame don't apply to this example), includes following steps: Firstly, to fabricate air duct panels (namely non-combustible sandwich panels). Its production process is as follows: place an inorganic layer 7 (namely the substrate of the non-combustible sandwich panel) in the mould by mechanical rolling; put the selected insulation layer 6 (the non-combustible material layer in the middle of non-combustible sandwich panels) on top of the inorganic layer 7; place an inorganic layer 7 on top of the insulation layer 6; as the inorganic layer 7 solidifies here forms the non-combustible sandwich air duct panel (as shown in FIG. 2 and FIG. 3); then cut air duct panel and form the main air duct panel and the branch air duct panel through following procedures: firstly, cut air duct panels according to the designed size; Secondly, cut the two sid

Example

Example 2

[0043]A fabrication process to connect branch ventilating ducts to main ventilating ducts, as shown in FIG. 5. In this example, the birdsmouth10 is located in the middle of one side plate of the main air duct11. The bonding faces of the birdsmouth are all of the right-angled flat shape. Four bonding faces of the connector21 are all of the right-angled flat shape as well. The connector21 are completed placed in the birdsmouth10 for the connection. Other processes are the same as Example 1.

Example

Example 3

[0044]A fabrication process to connect branch ventilating ducts to main ventilating ducts, as shown in FIG. 1 (exclusive of the steps within the broken lien frame), FIG. 6 and FIG. 7. In this example, the birdsmouth10 is located in the middle of one side plate of the main air duct11. The bonding faces of the birdsmouth are all of the right-angled flat shape. Four bonding faces of the connector21 are all of the right-angled ladder shape. The right-angled flat bonding faces are placed in the right-angled ladder-shaped bond faces for connection. The said adhesive is applied to the said right-angled ladder-shaped bonding faces. Other processes are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap