Colored curable composition, color filter and solid-state imaging device

a color filter and composition technology, applied in the direction of inks, disinfection, synthetic resin layered products, etc., can solve the problems of difficult layer thinning, low sensitivity, and increased concentration of coloring agents, and achieve excellent color, high sensitivity, and excellent developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

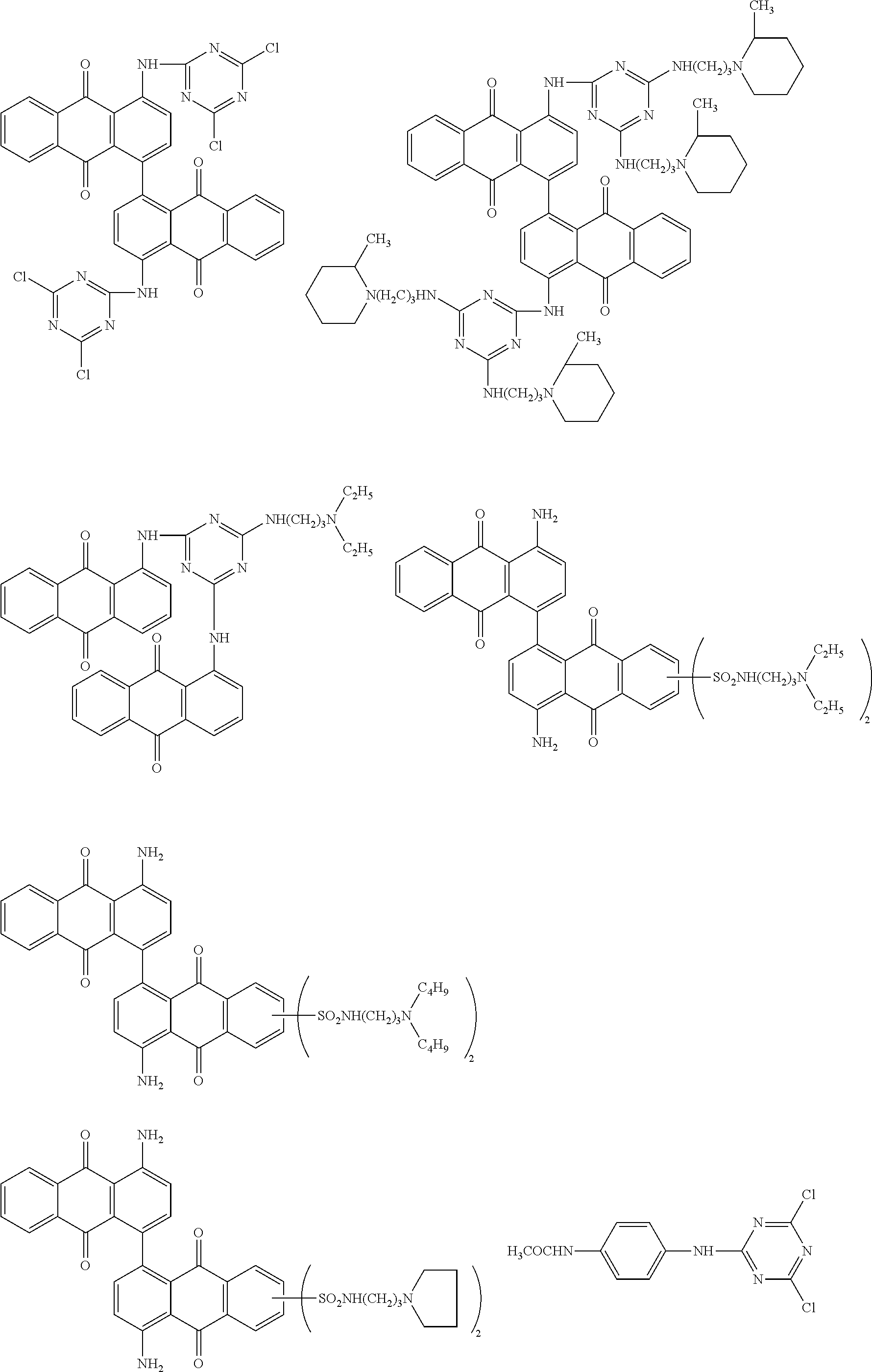

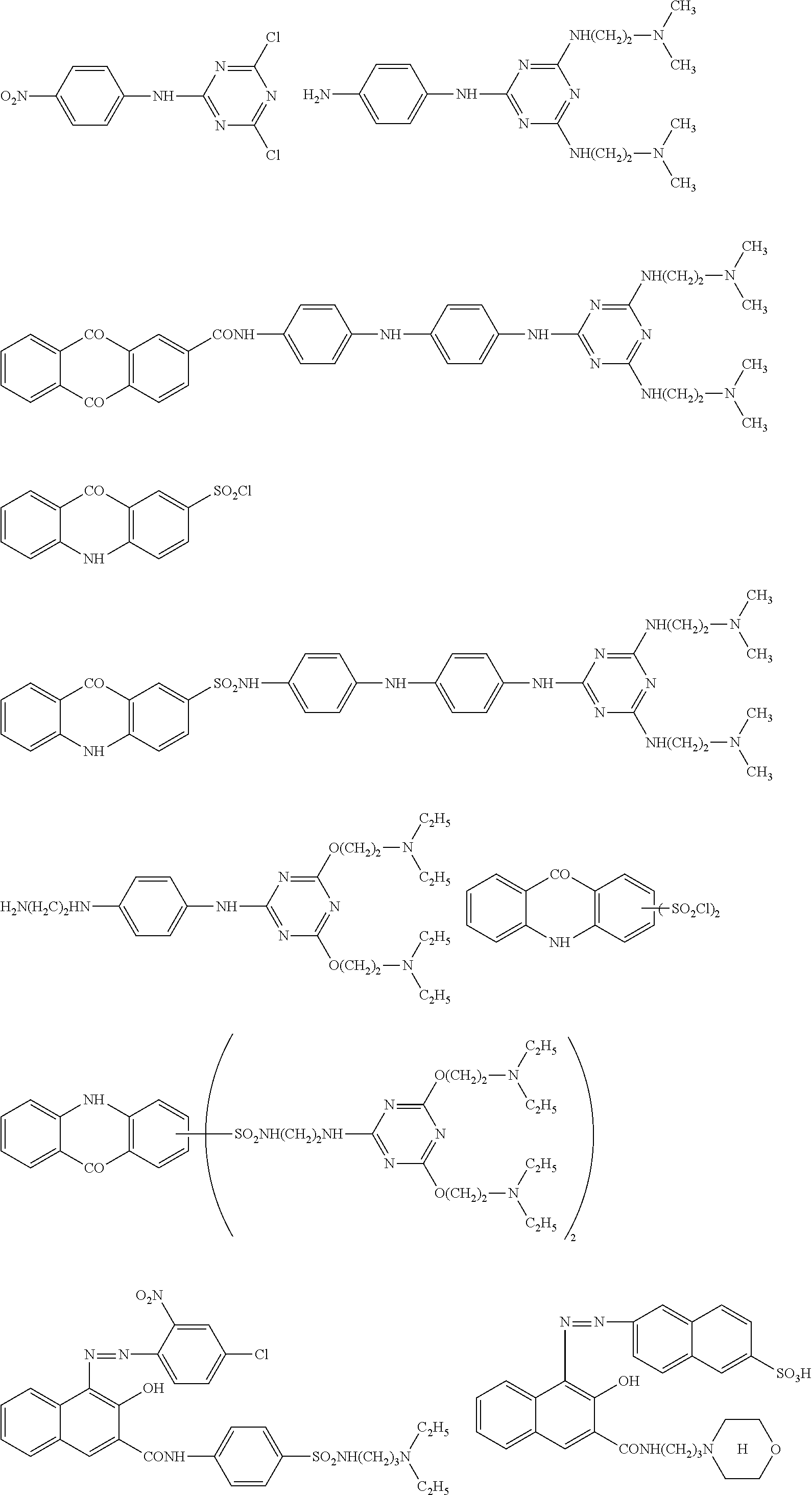

Method used

Image

Examples

synthesis example 1

Preparation of Specific Dispersion Resin solution 1

[0472]800 parts of cyclohexanone was introduced into a reaction container and then heated to 100° C. while nitrogen gas was injected into the container, and a mixture of 60.0 parts of styrene, 80.0 parts of methacrylic acid, 68.0 parts of methyl methacrylate, 62.0 parts of butyl methacrylate, and 9.0 parts of azobisisobutyronitrile was added dropwise at the same temperature for 1 hour and subjected to a polymerization reaction. After the dropwise addition, the reaction was continued at 100° C. for additional 3 hours, and a solution obtained by dissolving 2.0 parts of azobisisobutyronitrile in 50 parts of cyclohexanone was added thereto and subjected to reaction at 100° C. for an additional 1 hour to obtain a solution of a specific dispersion resin 1 having a weight-average molecular weight of about 30,000 and an acid value of 3.44 mmol / g. The weight-average molecular weight was measured by means of Gel Permeation Chromatography (GPC)

synthesis example 2

Preparation of Specific Dispersion Resin Solution 2

[0474]To the specific dispersion resin solution 1 obtained in Synthesis Example 1 were added 10 parts by mass of glycidyl methacrylate and 1 part by mass of tetraethylammonium bromide, followed by stirring at 90° C. for 2 hours to obtain a solution of a specific dispersion resin 2 having a double bond group introduced in the side chain, and having a weight-average molecular weight of about 32,000 and an acid value of 3.1 mmol / g.

[0475]To the solution of the specific dispersion resin 2 cyclohexanone (solvent) was added to prepare a specific dispersion resin solution 2 having a nonvolatile content of 20% by mass.

synthesis example 3

Preparation of Specific Dispersion Resin Solution 3

[0476]To 333 parts by mass of propylene glycol monomethyl ether acetate solution containing 100 parts by mass of poly acrylic acid / methyl methacrylate (mass ratio 50 / 50) having a weight-average molecular weight of 10,000 and an acid value of 6.9 mmol / g were added 50 parts by mass of glycidyl methacrylate and 1 part by mass of tetraethylammonium bromide, followed by stirring at 90° C. for 3 hours to obtain a solution of a specific dispersion resin 3 having a double bond group introduced in the side chain, and having a weight-average molecular weight of 12,000 and an acid value of 1.95 mmol / g.

[0477]To the solution of the specific dispersion resin 3 was added propylene glycol monomethyl ether acetate (solvent) to prepare a specific dispersion resin solution 3 having a nonvolatile content of 20% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap