Highly dispersible granulate for the preparation of formulations of high dosage active substances and procedure for obtaining high dosage active substances thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

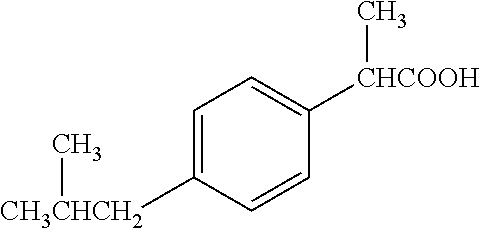

[0020]The invention represents a technological advance in this field, since it improves the release time of ibuprofen, with the beneficial effects that this entails.

[0021]More specifically, the tablet proposed by the invention focuses its characteristics on the fact that it incorporates two components, which participate therein with the following proportions:[0022]Ibuprofen between—96% and 97%[0023]Disaggregating agent—between 4% and 3%

[0024]As a disaggregating agent, one or a mixture of the following products may be used:[0025]Croscarmellose[0026]Crospovidone[0027]Sodium carboxymethyl starch (Primogel)

[0028]The procedure for obtaining and manufacturing the aforementioned tablet involves subjecting the mixture of the two aforementioned products to a dry compaction phase, preferably by means of a refrigerated roller compactor, in order to subsequently transform said compacted product into a granulated product, with the aid of a rotary or rolling granulator.

[0029]This granulated product

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap