Vehicle body and molding method thereof

a technology for vehicles and bodies, applied in the field of vehicles and molding methods, can solve the problems of heavy vehicle bodies, complex assembly process of vehicles, and relatively week-long strength of vehicles, and achieve the effect of simplifying the assembly process and increasing the strength of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

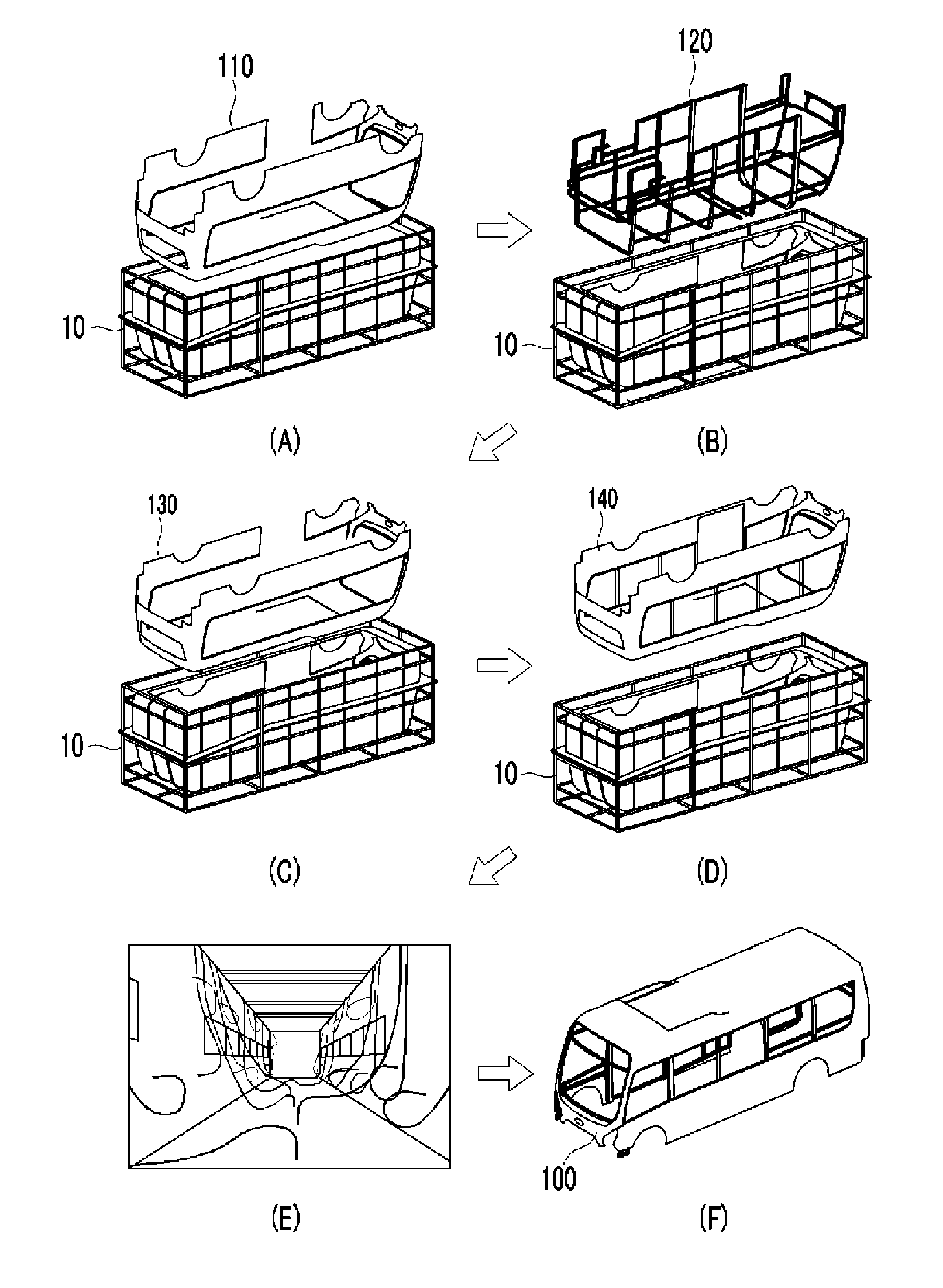

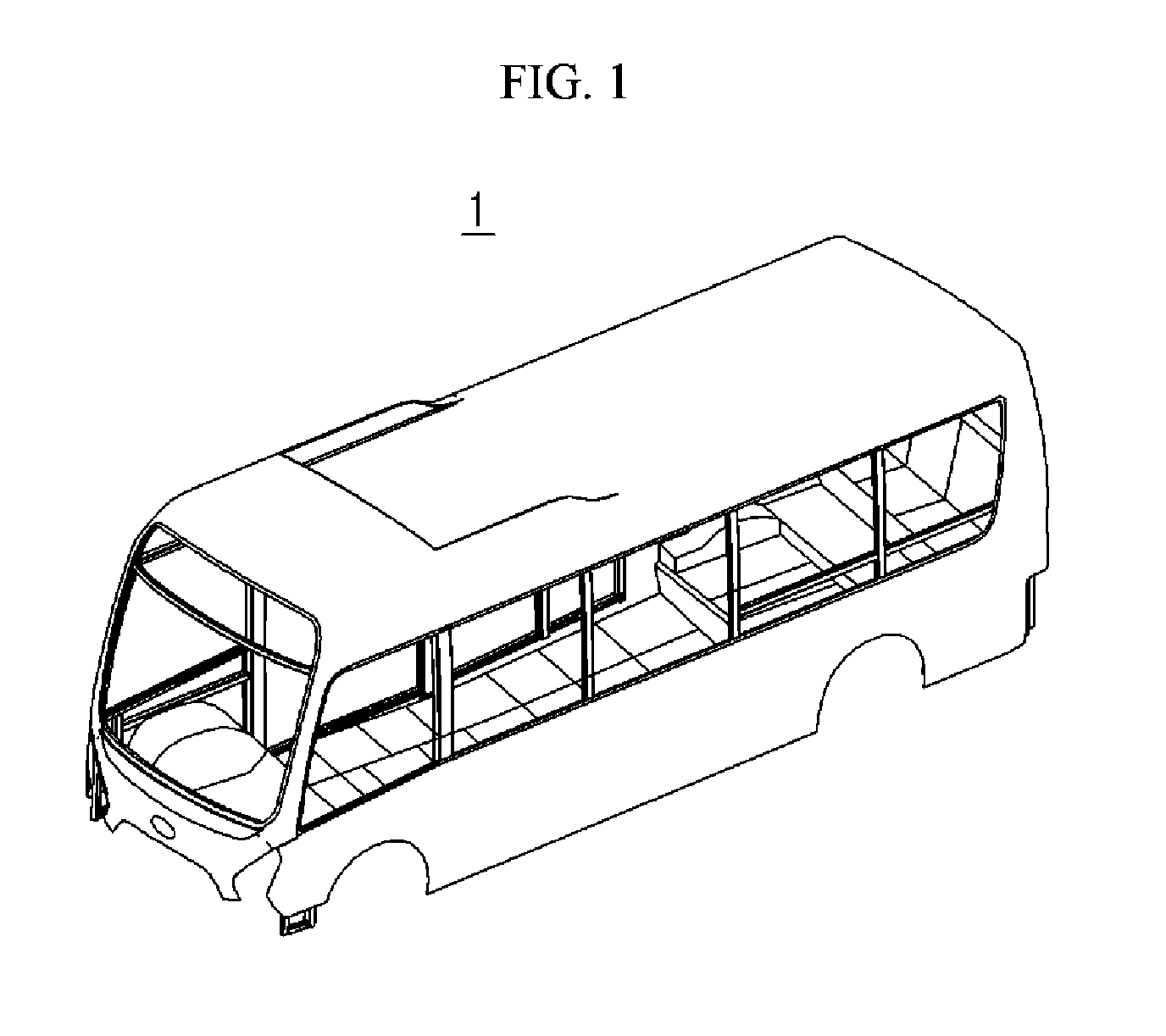

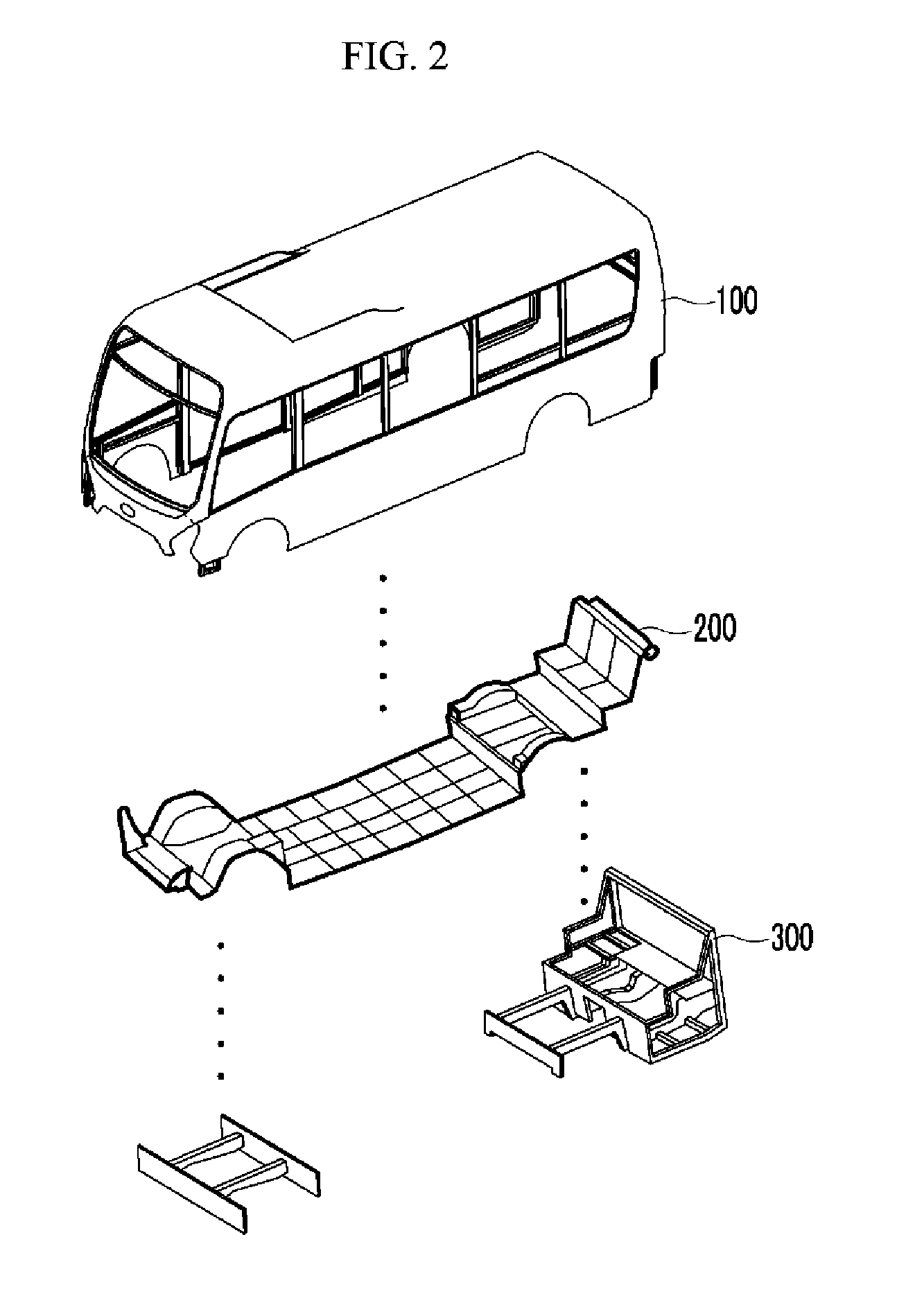

[0036]Reference will now be made in detail to various embodiments of the present invention(s), examples of which are illustrated in the accompanying drawings and described below. While the invention(s) will be described in conjunction with exemplary embodiments, it will be understood that present description is not intended to limit the invention(s) to those exemplary embodiments. On the contrary, the invention(s) is / are intended to cover not only the exemplary embodiments, but also various alternatives, modifications, equivalents and other embodiments, which may be included within the spirit and scope of the invention as defined by the appended claims.

[0037]Exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings so as to be easily practiced by a person skilled in the art.

[0038]Such exemplary embodiments are exemplary embodiments according to the present invention. Since a person skilled in the art can realize the present

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermoplasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap