Circuit board and on-board structure of semiconductor integrated circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

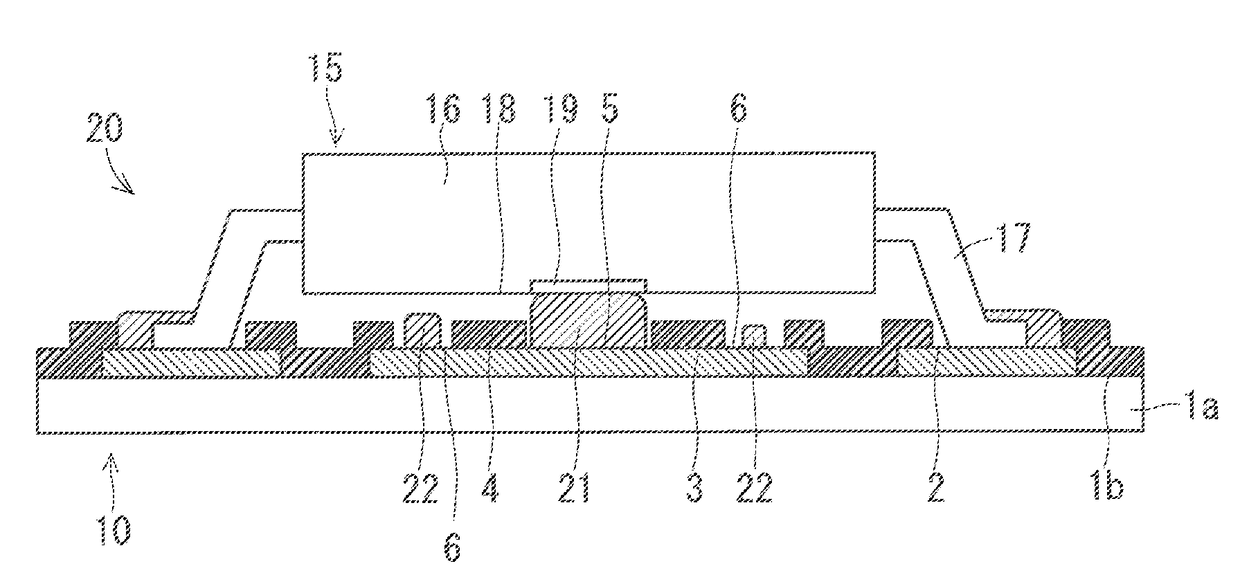

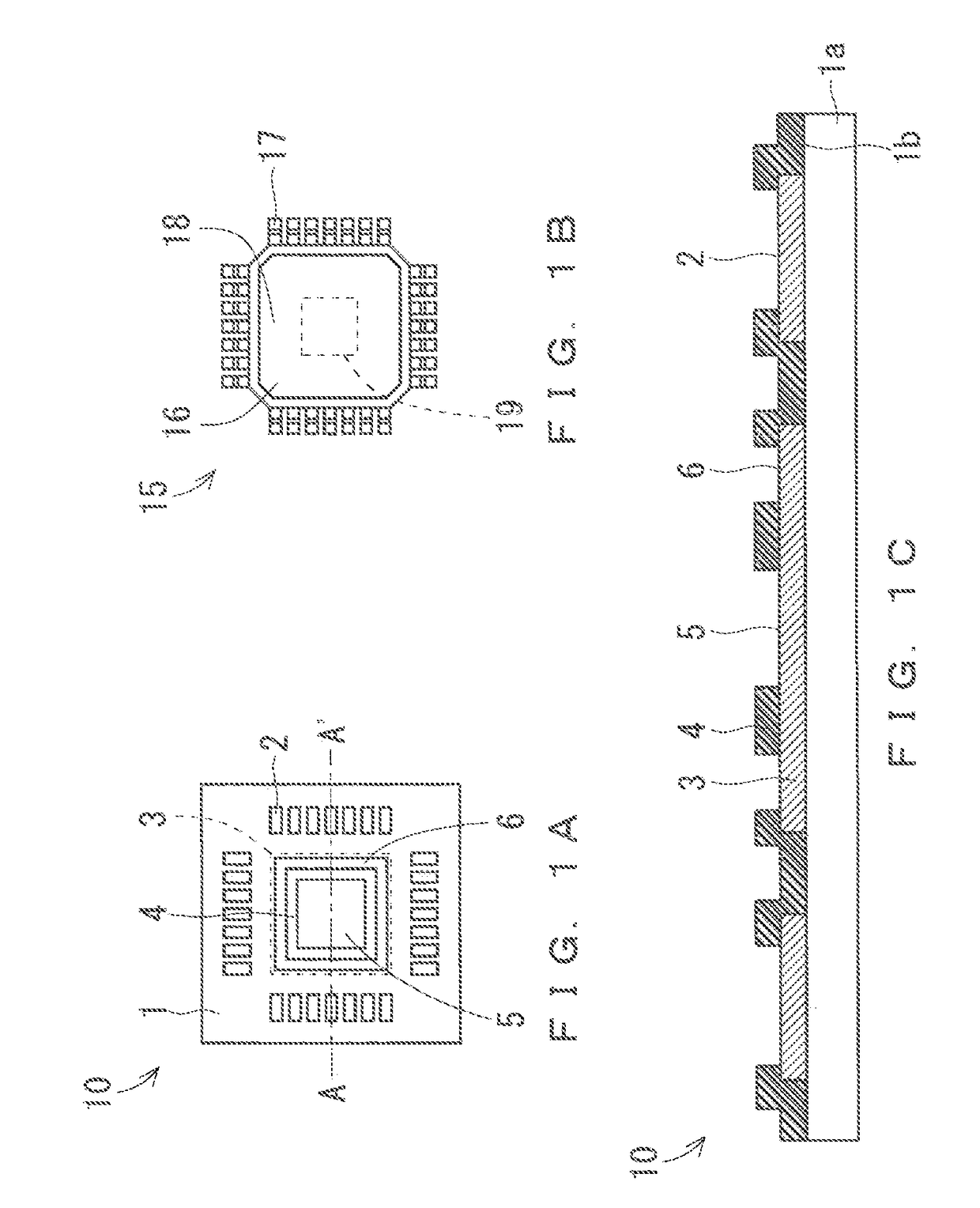

[0019]FIG. 1A is a plan view of the circuit board 10 in a first preferred embodiment.

[0020]FIG. 1B is a plan view of a semiconductor IC circuit 15 in the first preferred embodiment. FIG. 1C is a cross-sectional view of the circuit board 10 taken along the line A-A′ of FIG. 1A.

[0021]As illustrated in FIG. 1B, the semiconductor IC circuit 15 includes a package body 16 that accommodates a semiconductor chip (not shown) and terminals 17 aligned along at least part of the periphery of the package body 16. The semiconductor IC circuit 15 is a circuit of the surface-mounted quad flat package (QFP) type, with a plurality of leads, namely, the terminals 17 aligned along the four sides of the package body 16.

[0022]The semiconductor IC circuit 15 also includes a heat-dissipating unit 19 located in the rear surface thereof, or, in a joint surface 18 (see FIG. 2B), which faces the circuit board 10 having the semiconductor IC circuit 15 mounted thereon. The heat-dissipating unit 19 is to be joined t

second preferred embodiment

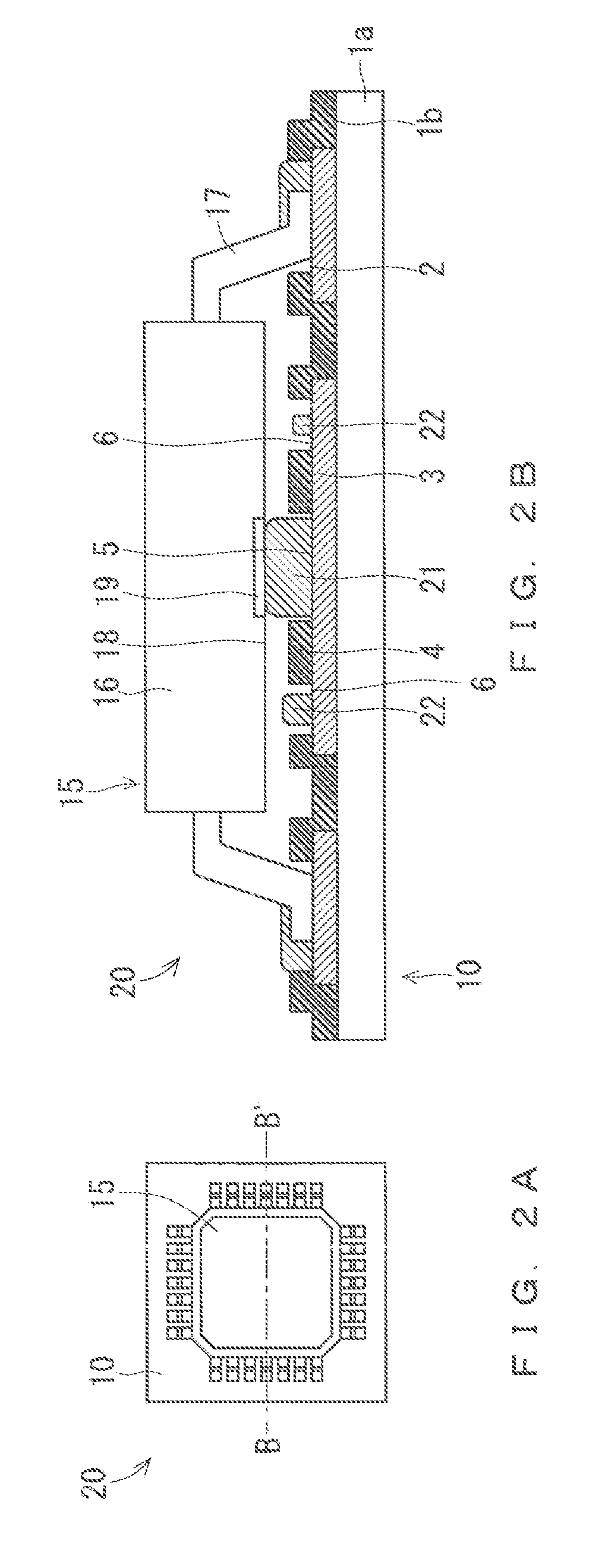

[0042]The following will describe the circuit board 10 and the on-board structure 20 of the semiconductor IC circuit 15 according to a second preferred embodiment. The configuration and operation similar to those described in the first preferred embodiment will not be further elaborated here.

[0043]FIG. 3 is a plan view of the circuit board 10 in the second preferred embodiment. The circuit board 10 includes second open areas 7 as well as the heat-dissipating connection pad 5 and the first open area 6 mentioned in the first preferred embodiment. In the individual second open area 7, the metal layer 3 is exposed as the outermost layer of the substrate 1 from an opening in the insulating layer 4 located between the heat-dissipating connection pad 5 and the first open area 6. One end of the individual second open area 7 is connected to the heat-dissipating connection pad 5, whereas the other end is connected to the first open area 6. In the second preferred embodiment, each of the second o

third preferred embodiment

[0047]The following will describe the circuit board 10 and the on-board structure 20 of the semiconductor IC circuit 15 according to a third preferred embodiment. The configuration and operation similar to those described in the first preferred embodiment will not be further elaborated here.

[0048]FIG. 4 is a plan view of the circuit board 10 in the third preferred embodiment. The circuit board 10 includes the heat-dissipating connection pad 5 shaped in an octagon. The circuit board 10 also includes the second open areas 7, each of which is a triangle whose base is one of the eight sides of the octagonal heat-dissipating connection pad 5 and is opposed to the base of another triangle, with the apex of each triangle located on a radial line extending from the center of the octagon. In addition, the circuit board 10 includes the first open areas 6, each of which is a circle whose arc includes the apex of the corresponding one of the triangles. Each of the triangular second open areas 7 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap