Method for designing layout of semiconductor device and method for manufacturing semiconductor device using the same

a semiconductor device and layout design technology, applied in the direction of cad circuit design, semiconductor/solid-state device details, instruments, etc., can solve the problems of significant time, trial and error, and design a layout of a semiconductor device using a layout design tool, and achieve the effect of reducing the layout design tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

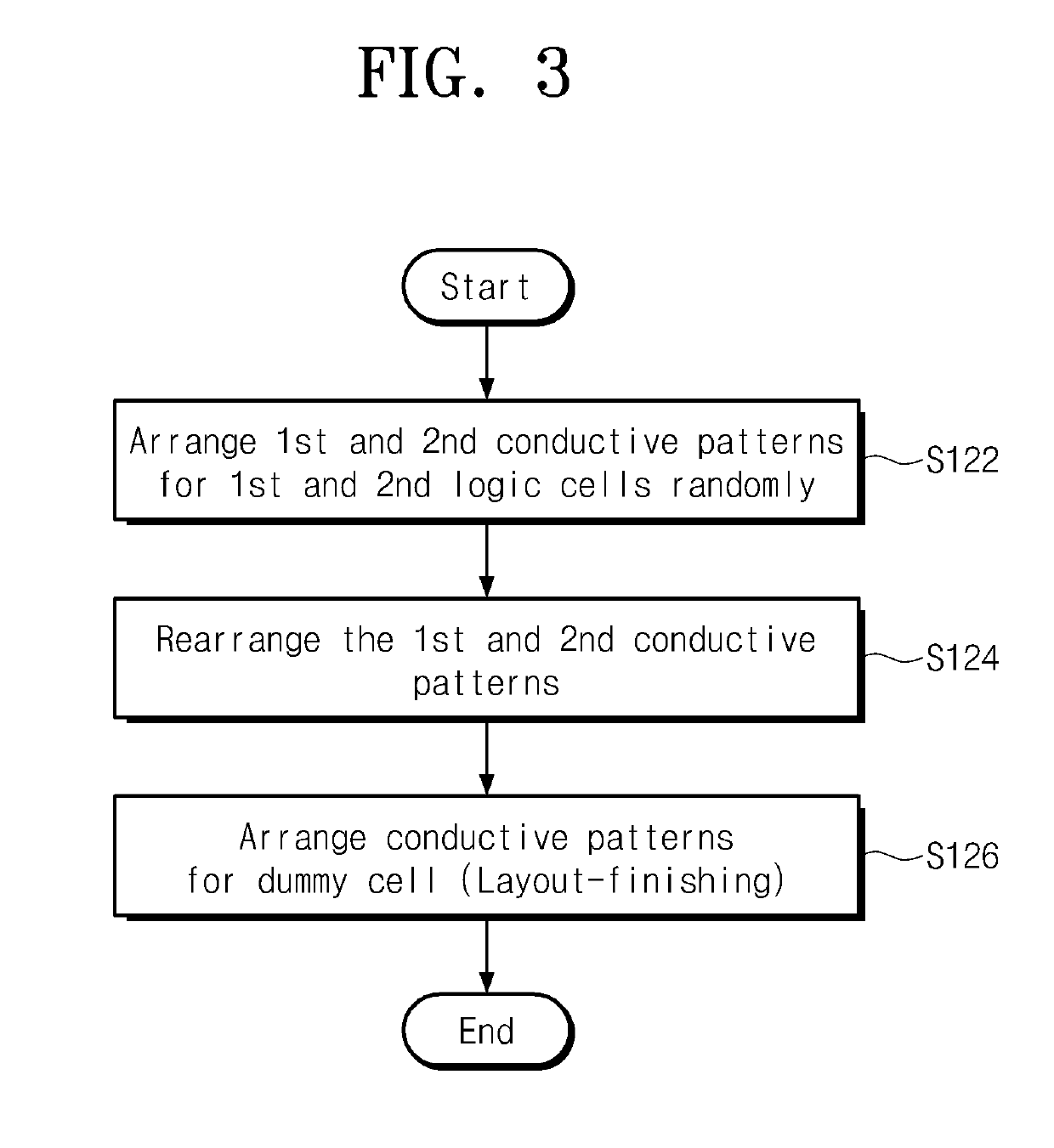

[0032]It is to be understood that both the foregoing general description and the following detailed description are provided as examples, for illustration and not for limiting the scope of the inventive concept. Reference will now be made in detail to the exemplary embodiments, which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

[0033]It will be understood that when an element is referred to as being “connected,” or “coupled,” to another element or layer, it can be directly connected or coupled to the other element or intervening elements may be present. In contrast, when an element is referred to as being “directly connected,” or “directly coupled,” to another element, there are no intervening elements present. As used herein, the term “and / or,” includes any and all combinations of one or more of the associated listed items.

[0034]Although the terms first, sec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap