Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Cermet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cermet is a composite material composed of ceramic (cer) and metal (met) materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used as a binder for an oxide, boride, or carbide. Generally, the metallic elements used are nickel, molybdenum, and cobalt. Depending on the physical structure of the material, cermets can also be metal matrix composites, but cermets are usually less than 20% metal by volume.

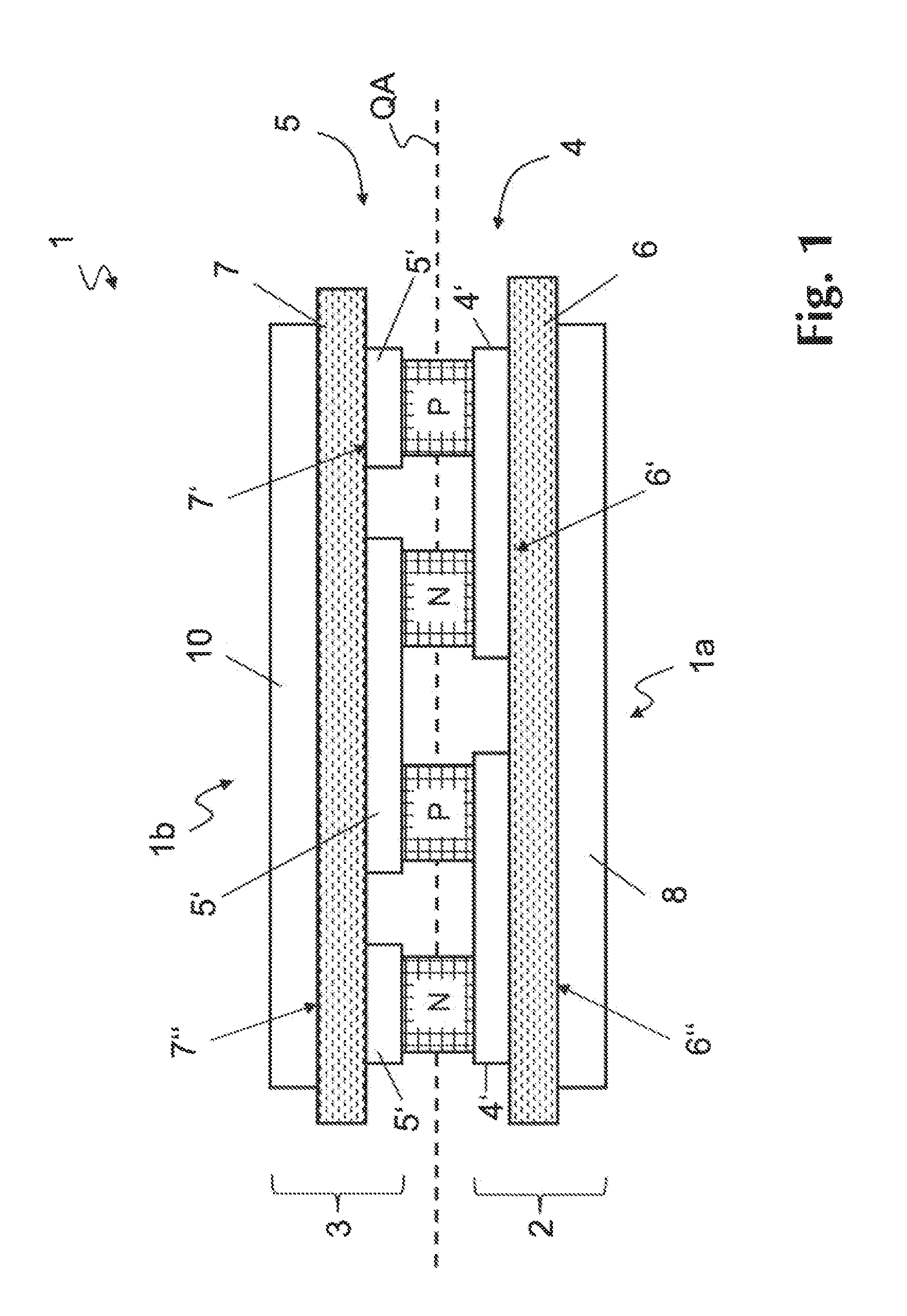

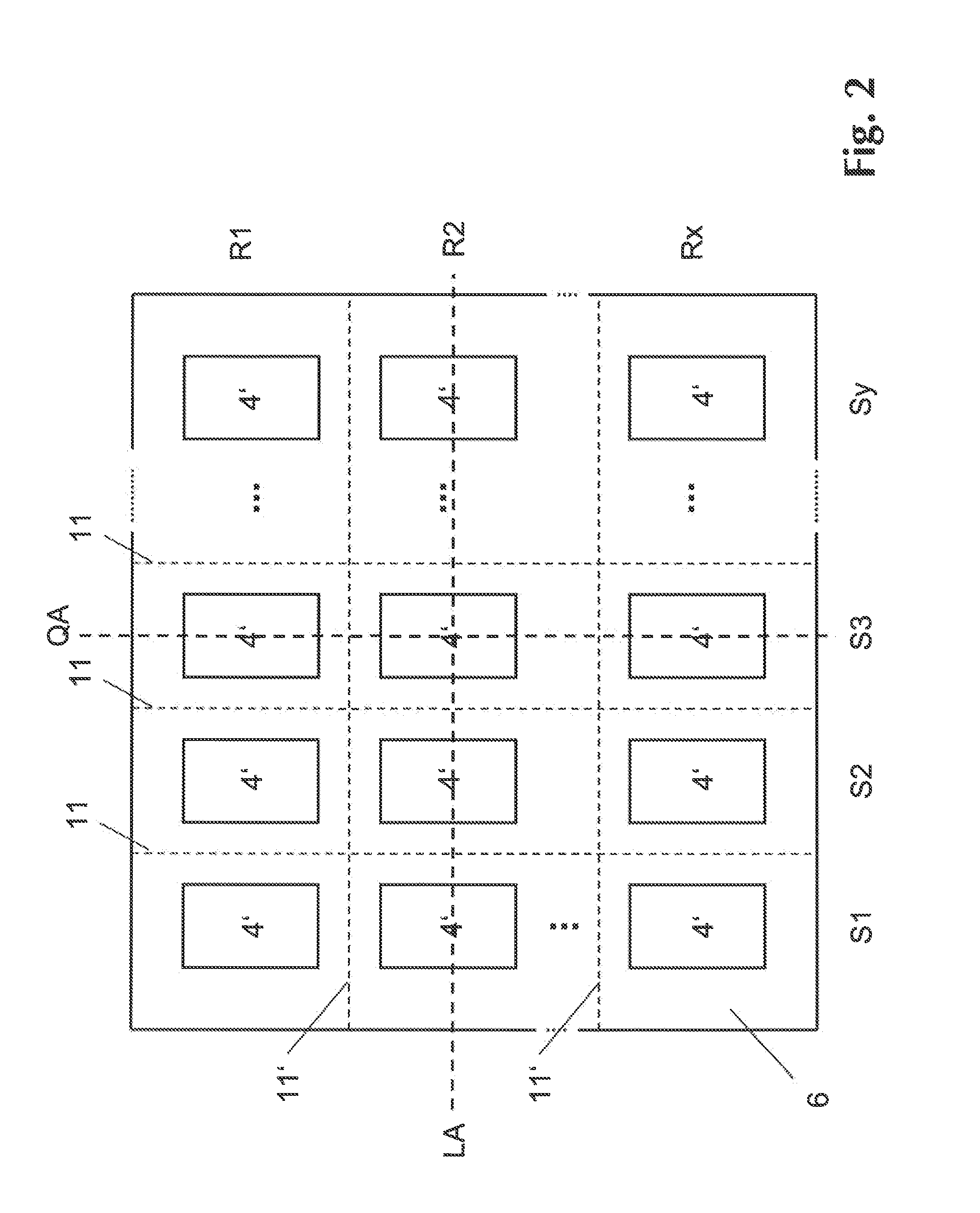

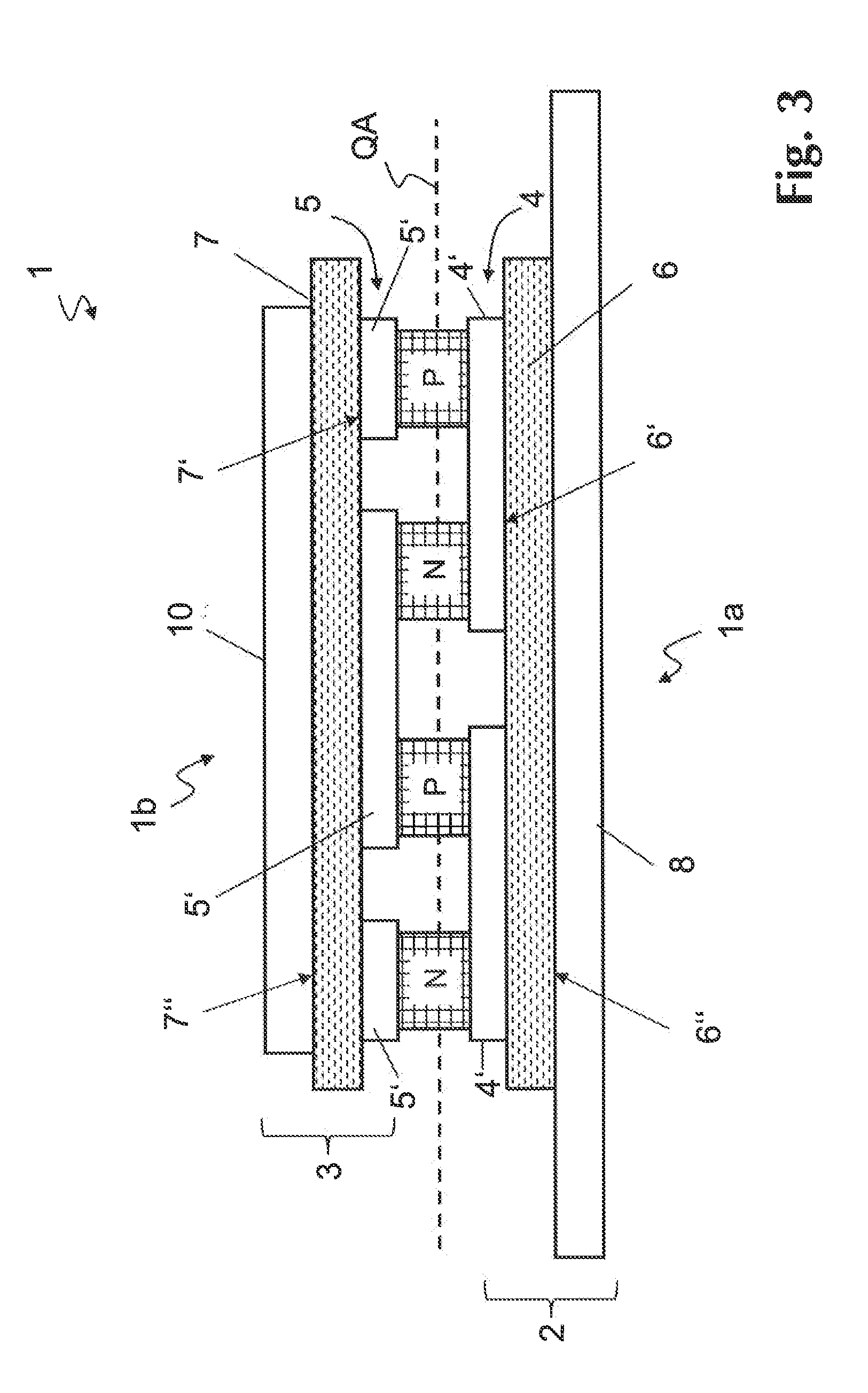

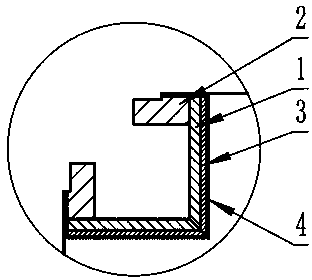

Thermoelectric generator module, metal-ceramic substrate and method of producing such a metal-ceramic substrate

InactiveUS20140345664A1Simple and reliable attachmentCircuit thermal detailsThermoelectric device with peltier/seeback effectHot zoneCeramic substrate

Owner:ROGERS GERMANY

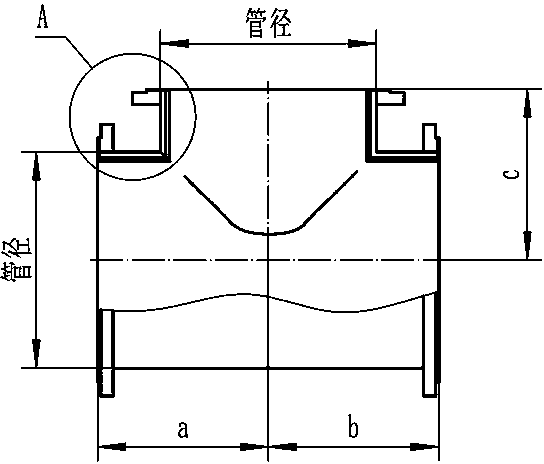

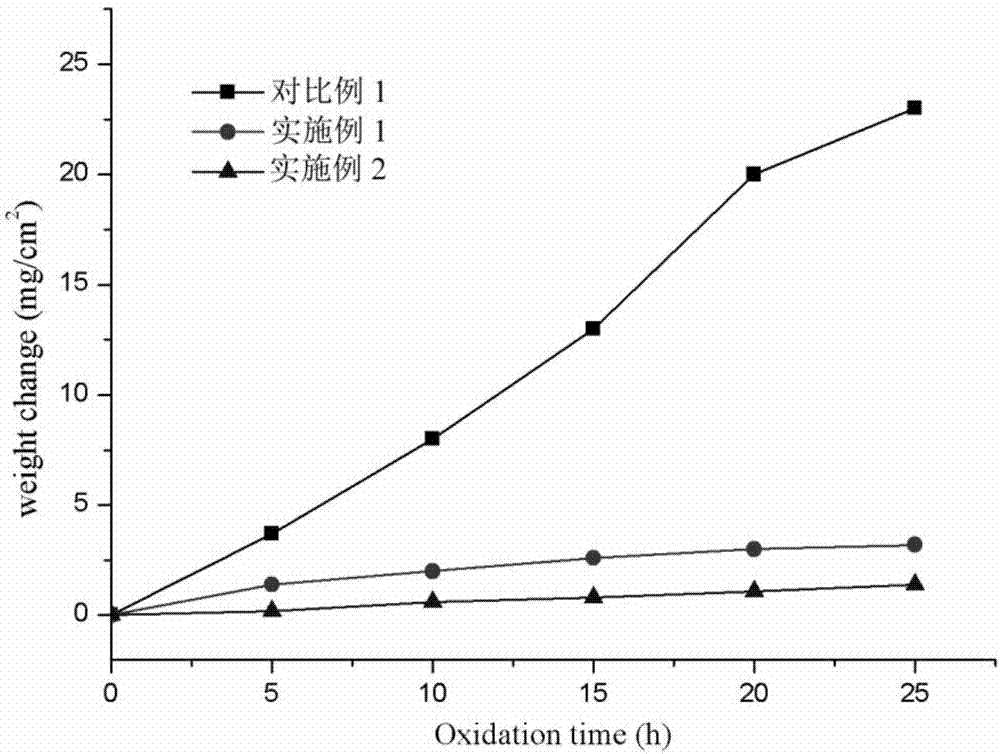

Manufacturing method for large-caliber abrasion-resistant corrosion-resistant ternary composite pipe accessory

InactiveCN103411071ASolve labor-consumingTime consuming to solveBranching pipesCoatingsCeramic compositeInorganic particle

Owner:FUDAN UNIV

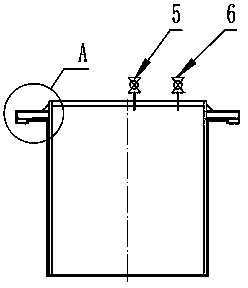

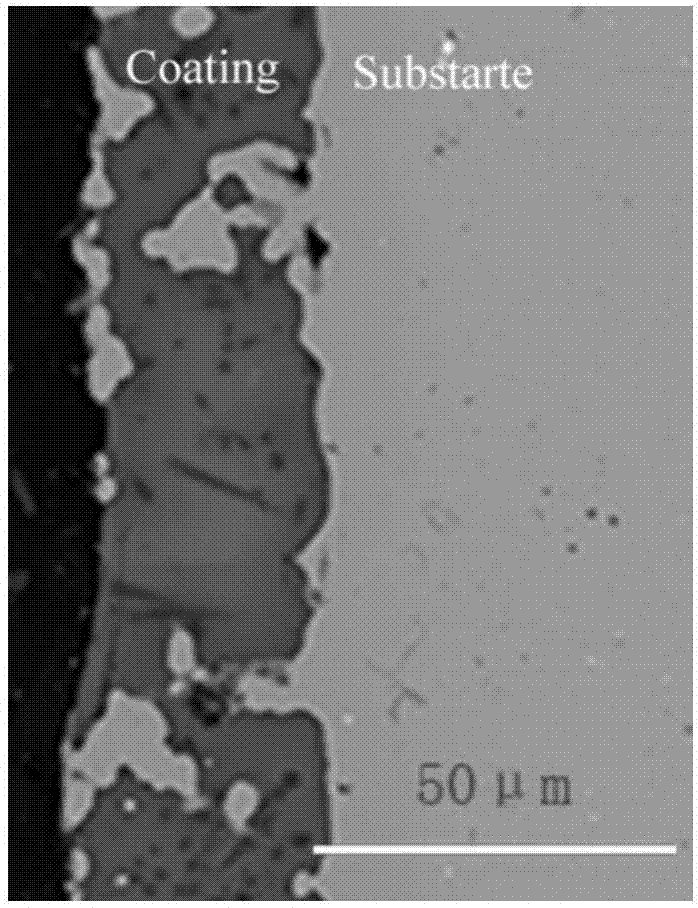

Copper alloy containing metal ceramic coating, and preparation method and application thereof

ActiveCN107570709AHot gas positive displacement engine plantsHeat inorganic powder coatingNickelCermet

Owner:CENT SOUTH UNIV

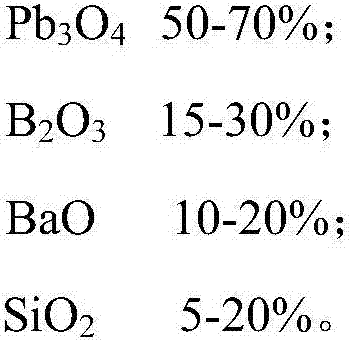

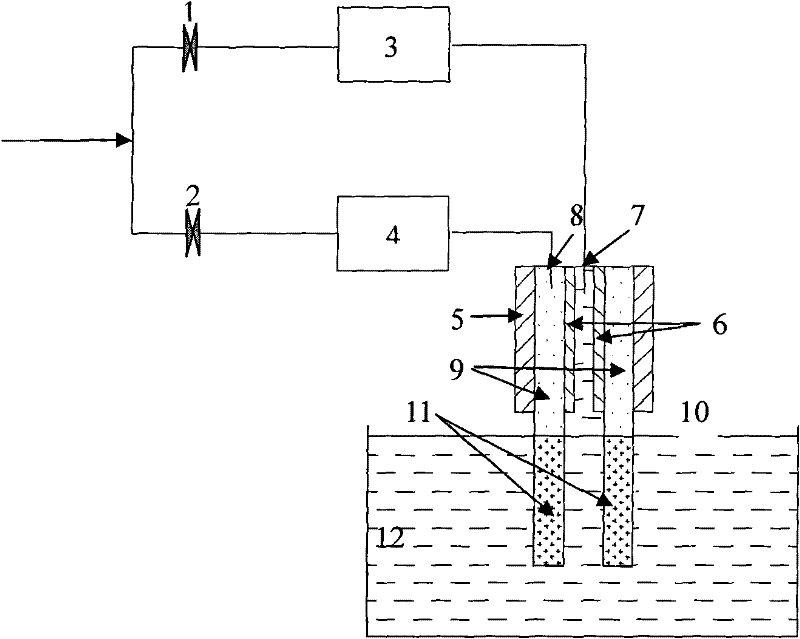

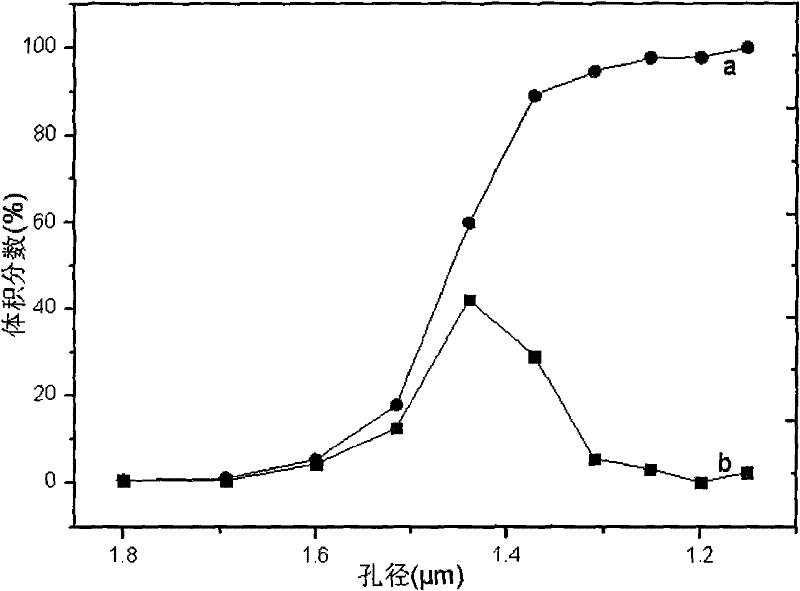

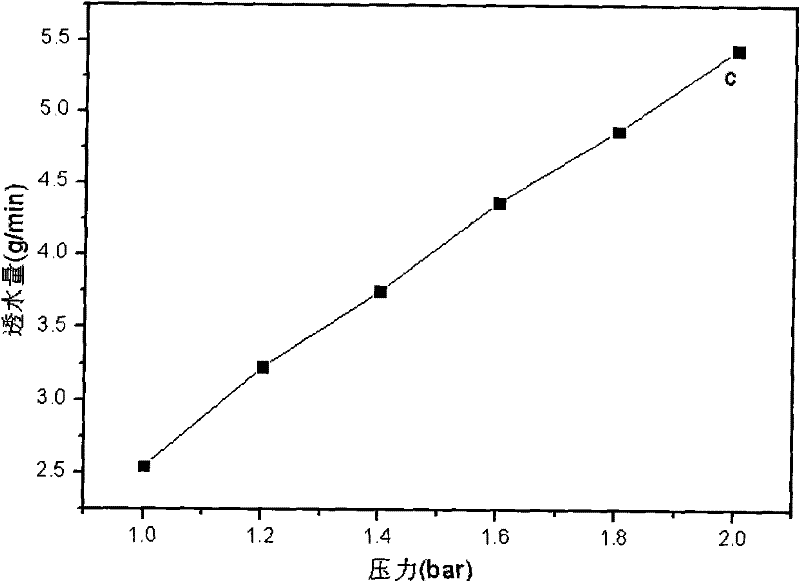

Metal-ceramic composite fibrous membrane tube and preparation method thereof

Owner:UNIV OF SCI & TECH OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap