Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Fault rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Failure mode based method for calculating failure probability of transformation device

InactiveCN105224782AUnderstand the impact of a failureAvoid Overhaul OmissionsSpecial data processing applicationsElectric power systemDevice failure

The present invention belongs to the field of on-line monitoring and fault diagnosis of a transformation device in a power system, and relates to a new failure mode based method for calculating a failure probability of the transformation device. The method in particular comprises: according to an established device fault tree, calculating an occurrence probability Pi(i=1,2...n) of various failure modes, severity Ii(i=1,2...n) of various failure modes, and criticality of various failure modes Wi(i=1,2...n) on the device. According to the present invention, when the various failure modes are mutually independent, a device failure rate lambda caused by the various failure modes can be computed according to a series model of a failure reliability theory, i.e., (reference to the specification), wherein computing of the defect occurrence probability Pi of various failure modes of transformation device is based on a defect probability computing method of an online monitoring data statistic probability distribution regulation; computing of the severity Ii(i=1,2...n) of defect corresponds to various failure modes is obtained according to the development process of a device defect, and developmental and changing rules of a characteristic parameter; and the criticality of various failure modes Wi is obtained by using a fuzzy hierarchical analysis method.

Owner:NORTH CHINA ELECTRIC POWER UNIV +2

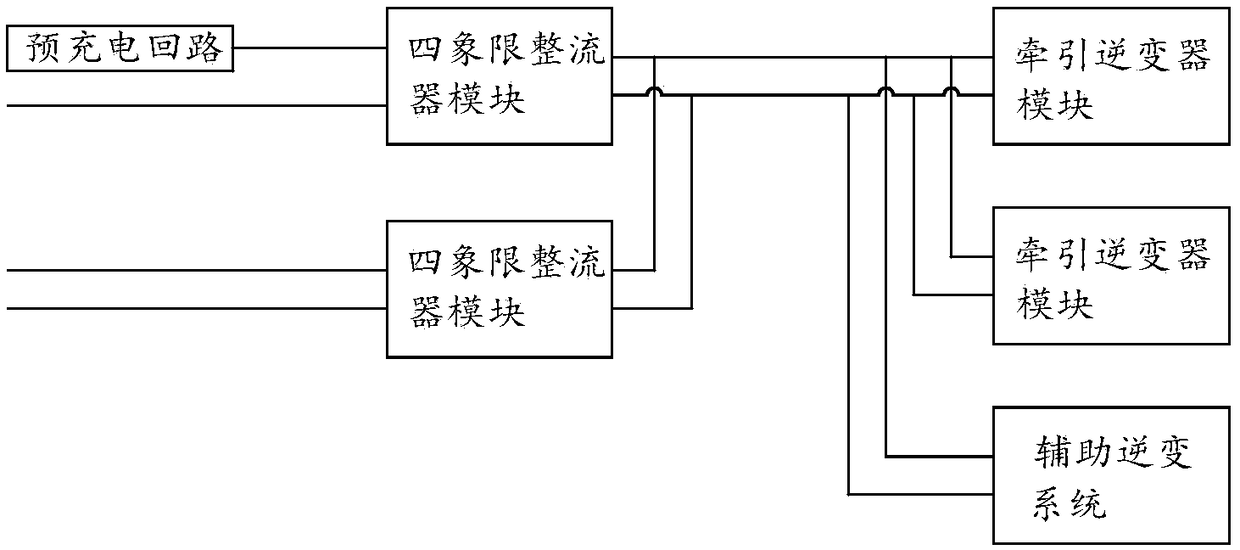

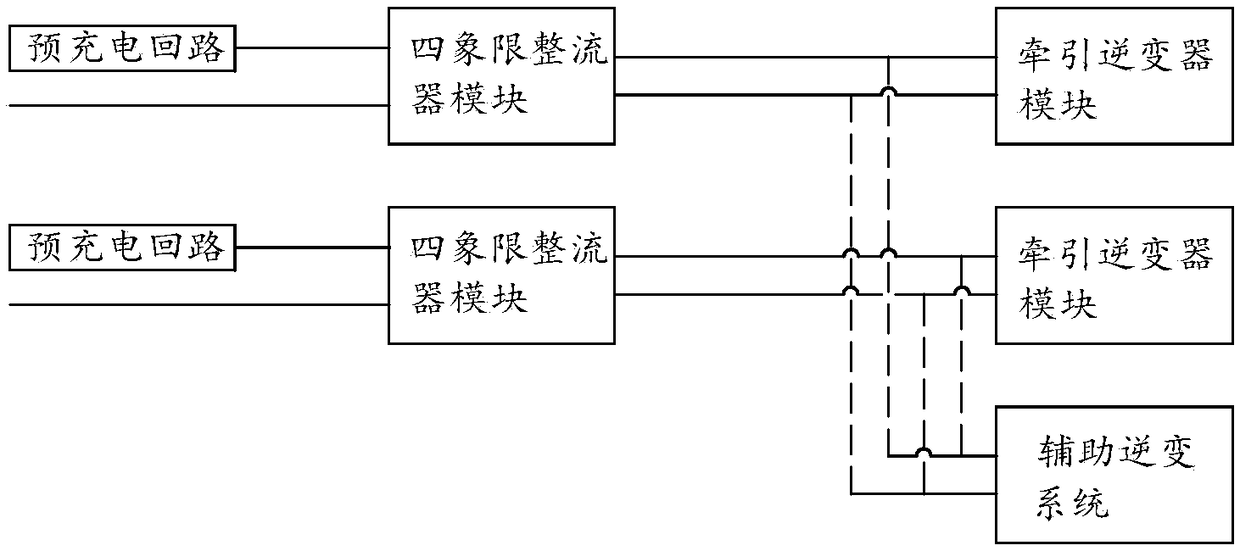

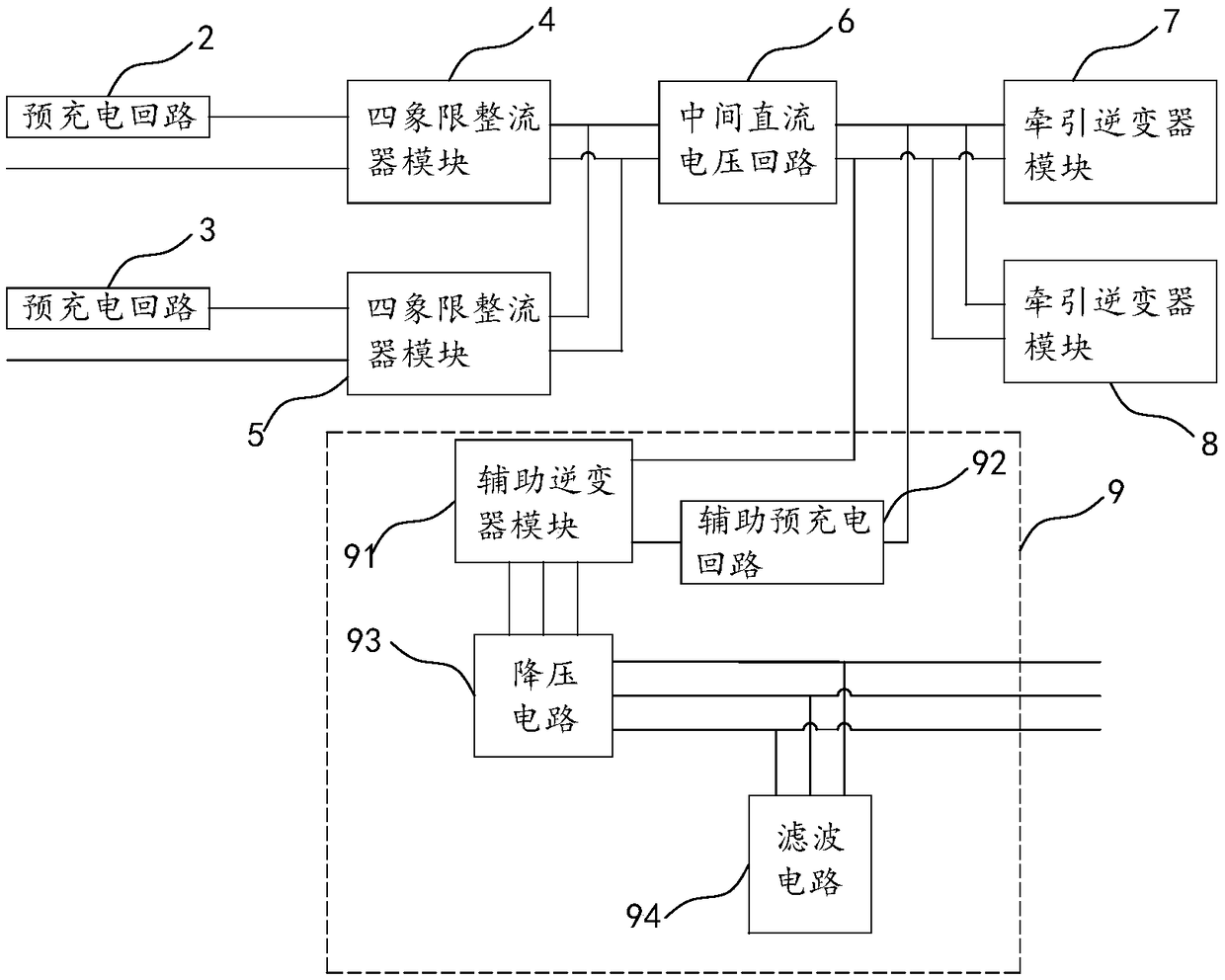

Traction converter and control, fault processing and carrier phase shifting methods thereof

InactiveCN108696149AImprove robustnessLow failure rateAc-ac conversionEmergency power supply arrangementsCarrier signalPre-charge

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

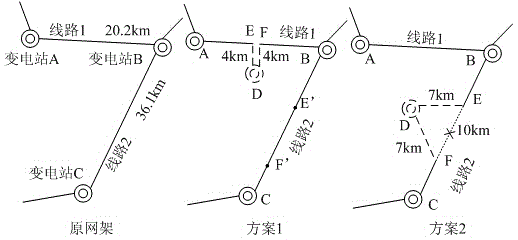

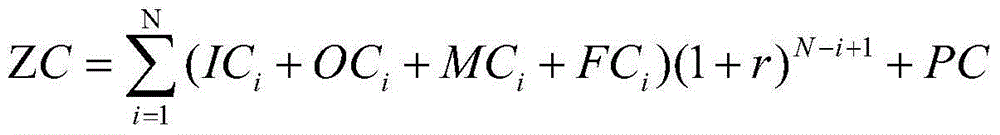

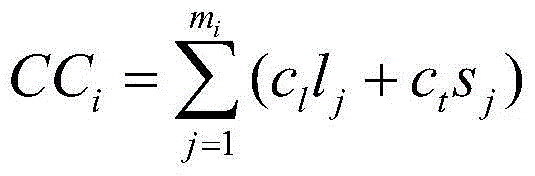

Method for optimizing power grid planning scheme based on comprehensive cost model

InactiveCN104680254AForecastingInformation technology support systemInterval methodLeast squares support vector machine

Owner:ZHEJIANG UNIV

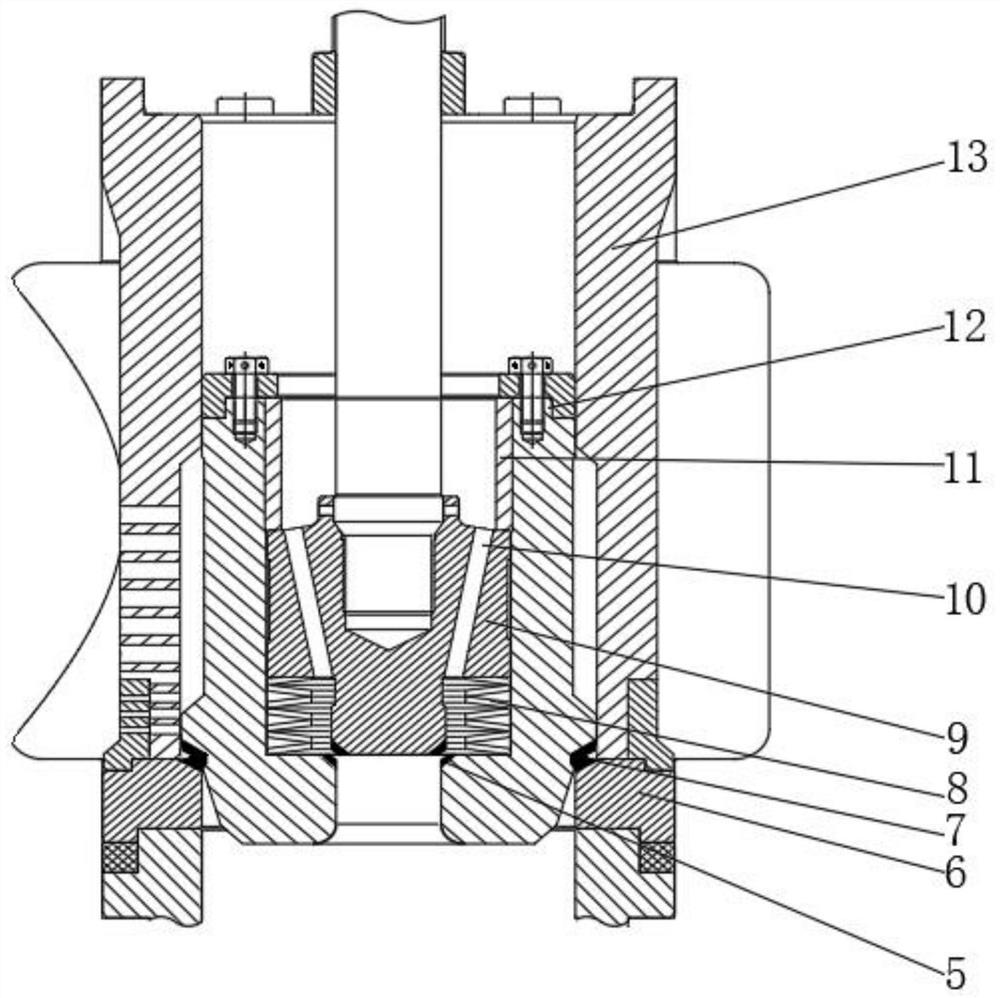

Jet engine

Owner:朴德春

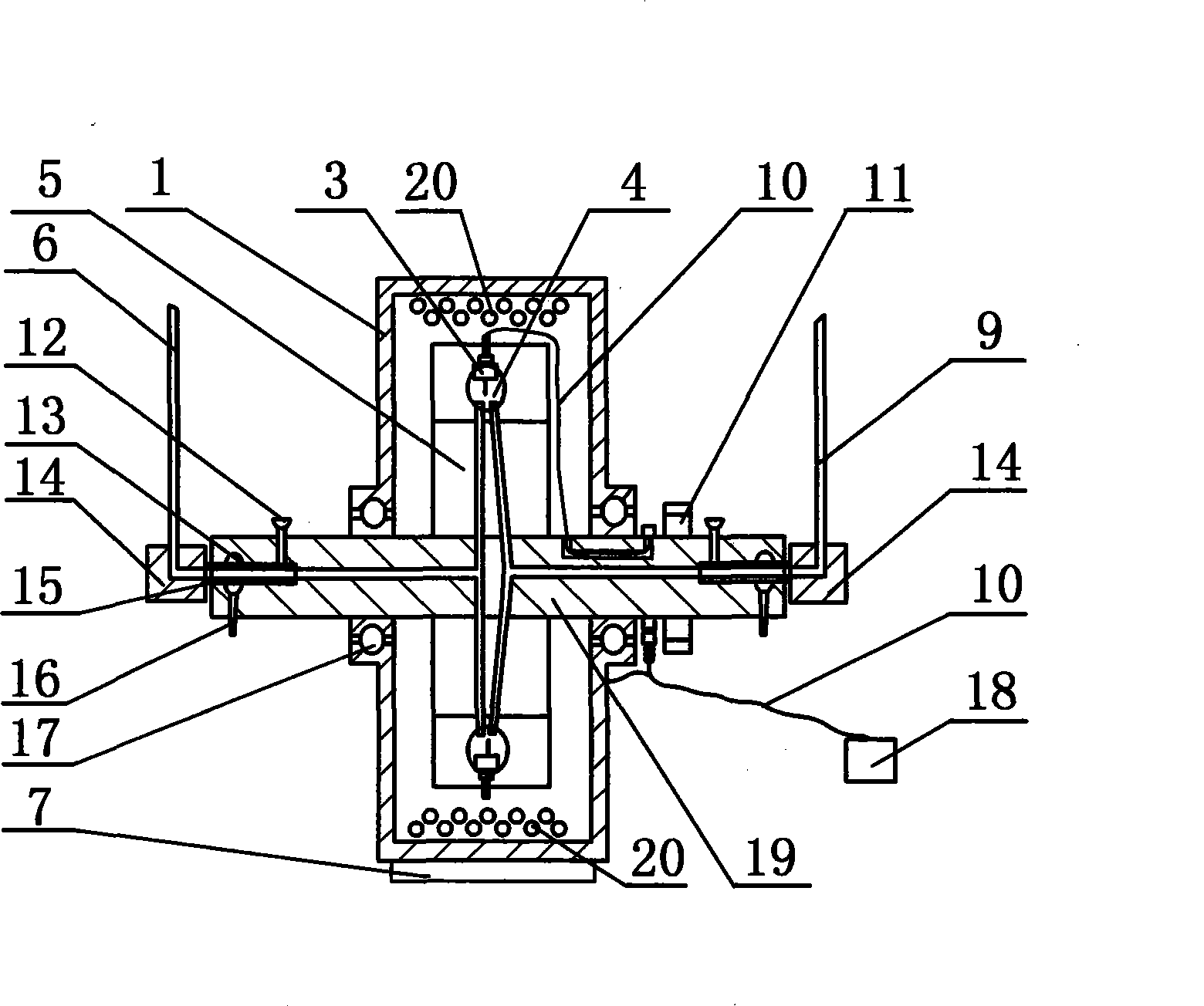

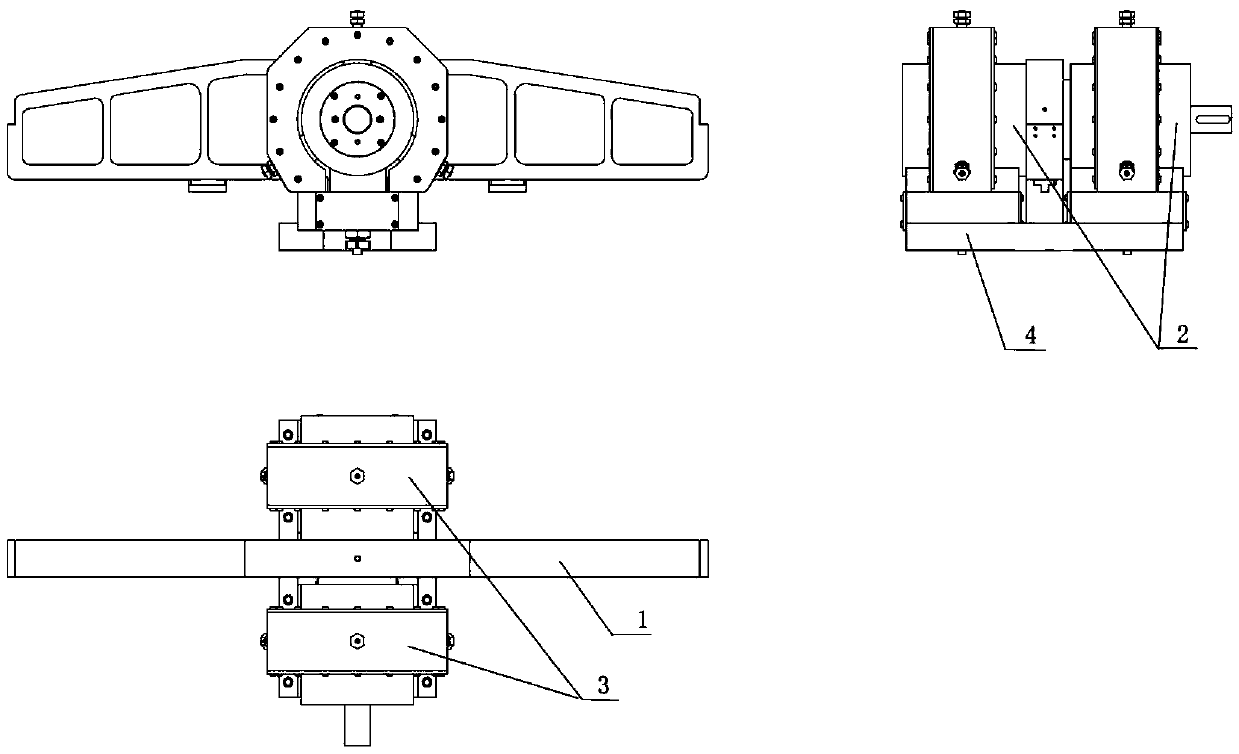

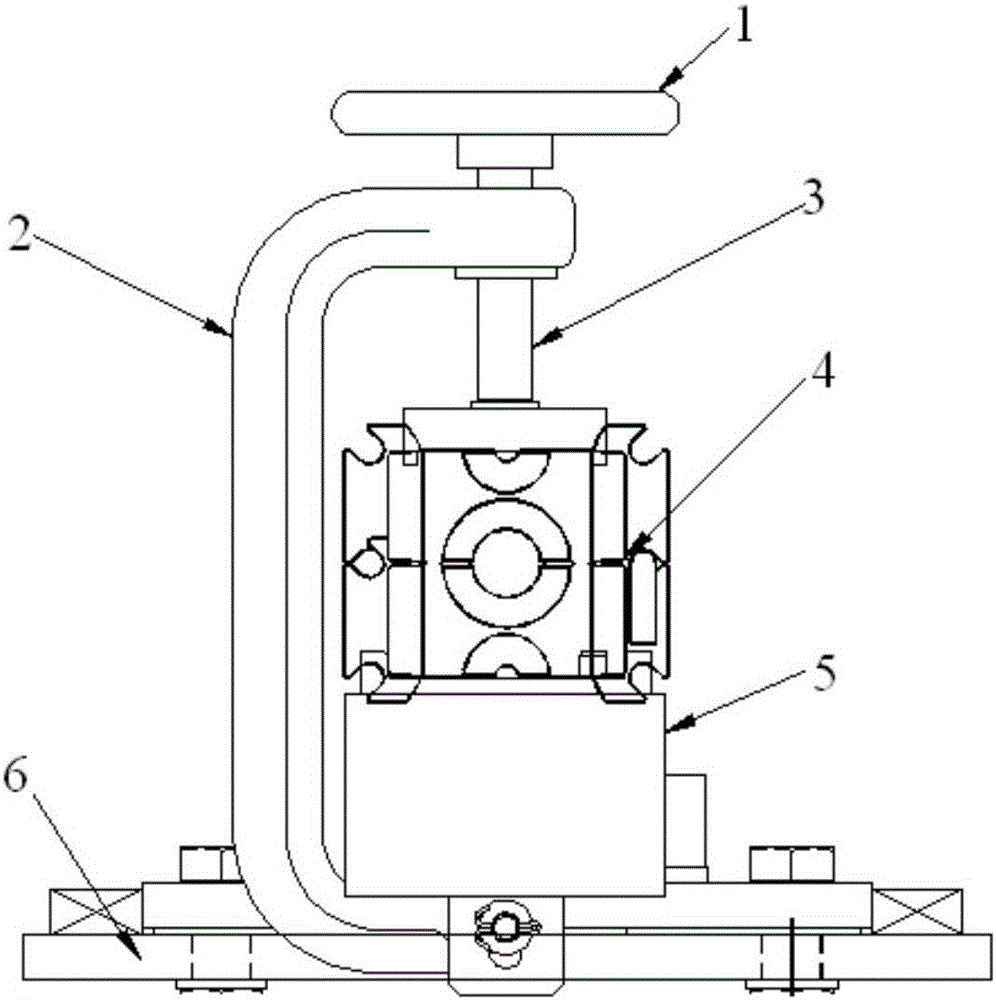

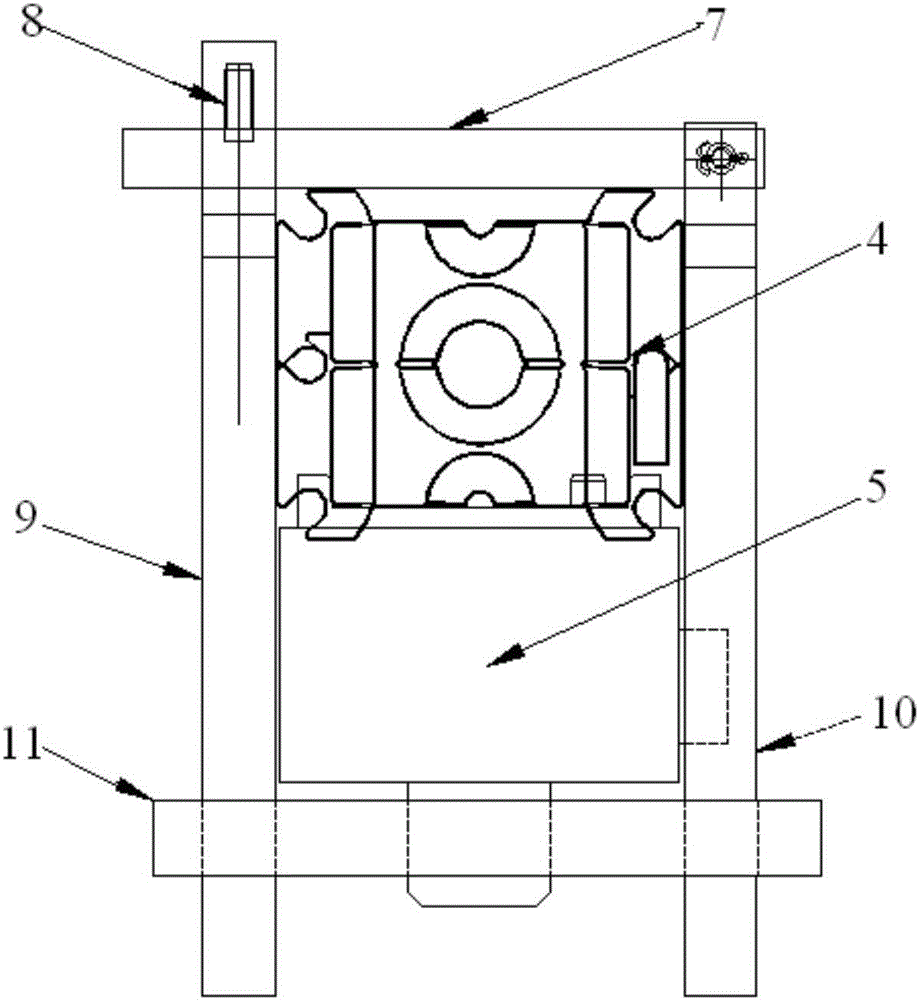

Combined type aerostatic bearing support mechanism

InactiveCN109580086ARelaxed working environmentGuaranteed stabilityForce/torque/work measurement apparatus calibration/testingEngineeringSymmetric structure

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Method for prolonging service life of server power supply

InactiveCN104133541AExtended service lifeLow failure ratePower supply for data processingFailure rateComputers technology

The invention discloses a method for prolonging the service life of a server power supply and belongs to the field of computer technology. The method comprises the steps that firstly, an FW determines how many power modules should be switched on at the same time according to the power consumption of a server system, and other power modules are switched off; secondly, the FW numbers all the power modules and maintains two queues which are the running queue and the rest queue, when alternate switching is needed, one or more power modules are selected from the rest queue to be placed in the running queue and are switched on, and power modules in the same number are selected from the running queue to be placed in the rest queue and are switched off; finally, the FW conducts on-off operation on the power modules every once in a while alternately. Compared with the prior art, the method has the advantages that the service life of the power supply can be prolonged, the failure rate of the power supply can be reduced, and then operation and maintenance cost can be reduced for customers.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Method of weighted combination specs for enhanced manufacturing yield

InactiveUS7050934B1Improve production yieldSignificantly affectingPlug gaugesSimulator controlFailure rateFigure of merit

Embodiments of the invention provide methods for enhancing the downstream product yield without significantly affecting the yield of components from which downstream products are made or enhancing yield of the components without significantly affecting the downstream product yield and performance. In one embodiment, a method comprises obtaining a failure rate of the downstream manufacturing process as a function of each of a plurality of component performance parameters of the current manufacturing process of the component; optimizing weighted factors based on correlation between the current manufacturing process of the component and the downstream product, the weight factors each corresponding to one of the plurality of component performance parameters; and calculating figure of merits (FOM) with respect to the plurality of component performance parameters of the current manufacturing process of the component, the FOM including the weighted factors.

Owner:WESTERN DIGITAL TECH INC

Connector wire box fixed on camera bracket

InactiveCN105703291AIngenious structural designEasy to disassembleElectrical apparatusEngineeringFault rate

The invention relates to a connector wire box fixed on a camera bracket, and belongs to the technical field of a power scheduling and monitoring auxiliary device structure. The box comprises a box body mounted on the camera bracket; an openable and closable box cover is arranged on the box body; a holding device for fixing the box body on the camera bracket is arranged on the bottom surface of the box body; two sides of the bottom surface of the box body are equipped with an auxiliary balancing device; and the auxiliary balancing device matches with the holding device and is used for improving the stability of the box body. The box provided by the invention has the advantages of ingenious structure design, low manufacturing cost, good waterproof and sunproof effect, low fault rate and convenient maintenance.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

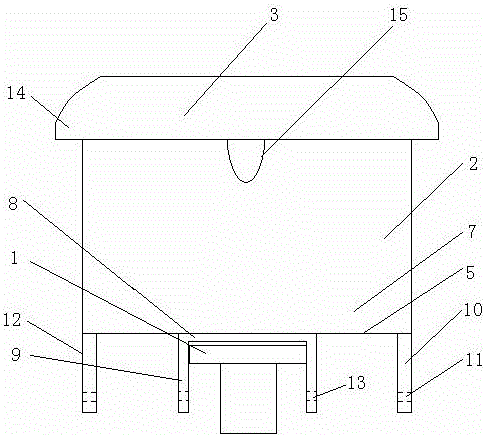

Temperature and pressure reducing valve

PendingCN113236791ASmall operating forceLow failure ratePressure relieving devices on sealing facesValve members for absorbing fluid energyThermodynamicsEngineering

Owner:YICHUAN TECH CHENGDU CO LTD

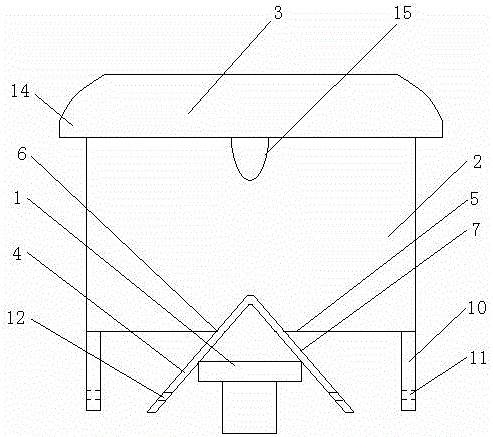

Fixing device for double-sided running groove of high-speed steel rolling production line

InactiveCN106180206APrevent looseningAvoid misalignmentRolling safety devicesMetal rolling arrangementsProduction lineManufacturing technology

Owner:WUHU XINXING DUCTILE IRON PIPES

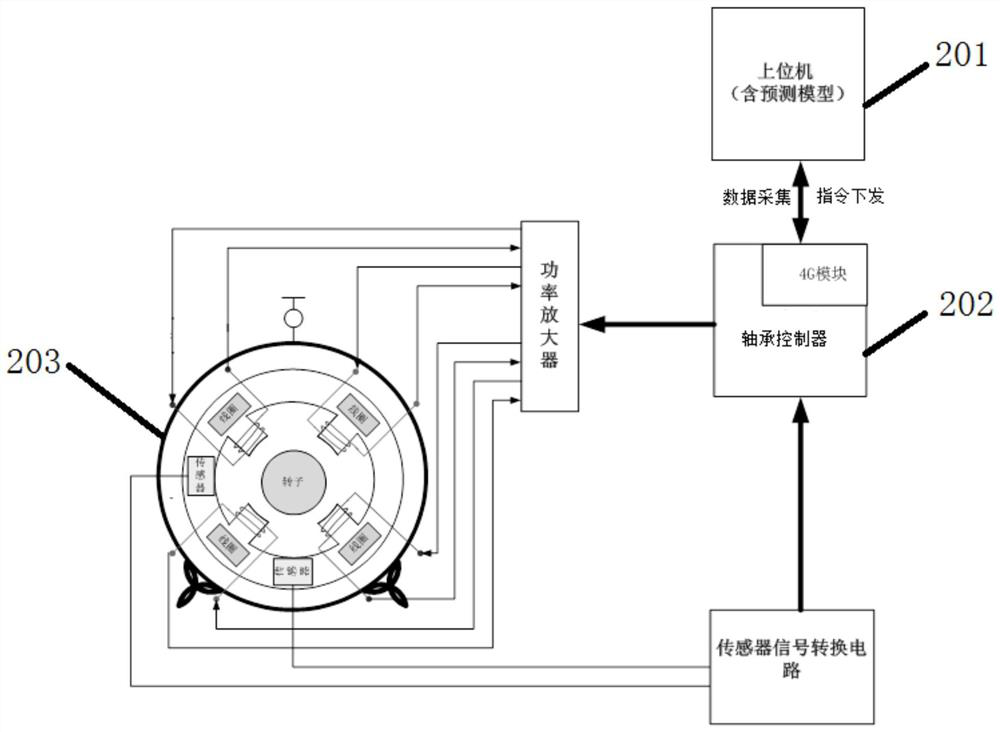

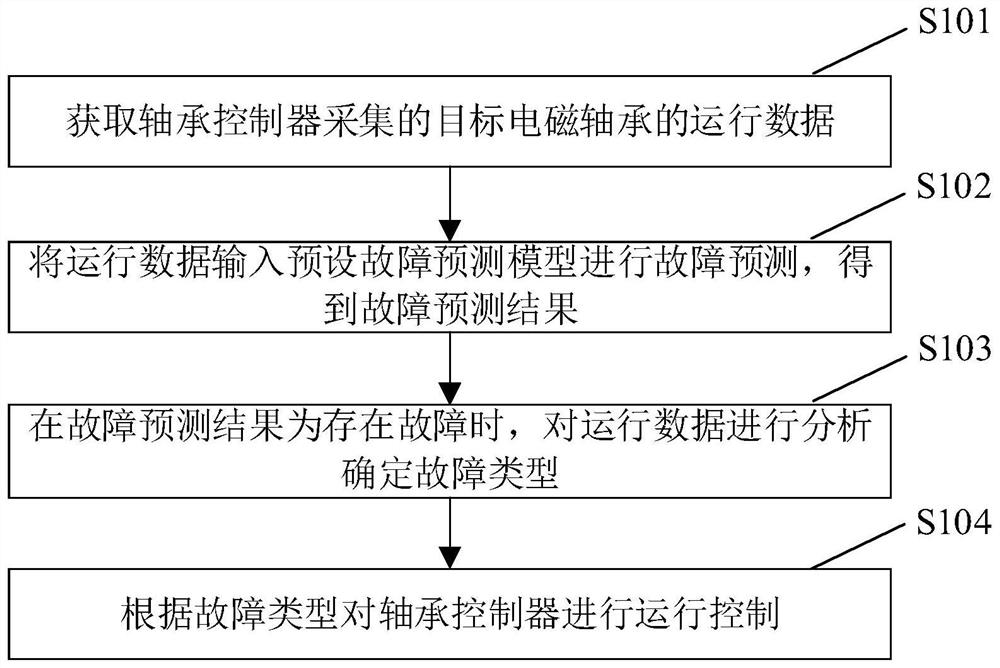

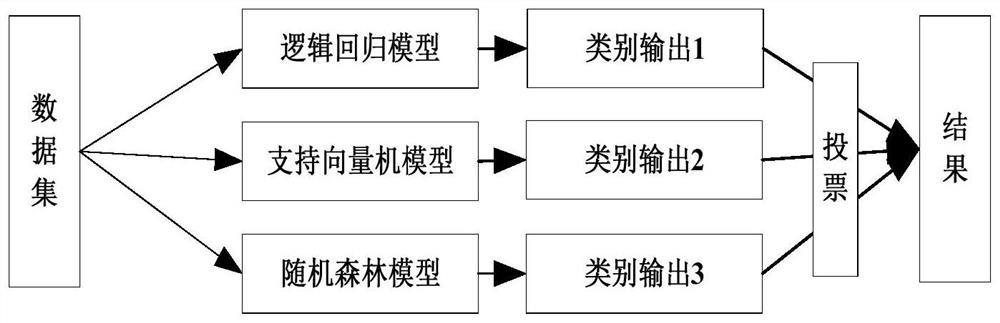

Electromagnetic bearing control method, device and system

Owner:GREE ELECTRIC APPLIANCES INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap