Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Gas bubble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for degrading industrial organic wastewater by ultrasonic wave ozone-microelectrolysis coupling

InactiveCN110776191AReduce surface tensionImprove permeabilitySpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsMolecular sievePtru catalyst

Owner:JIANGHUA WATER TREATMENT EQUIP PLANT JIANGSU

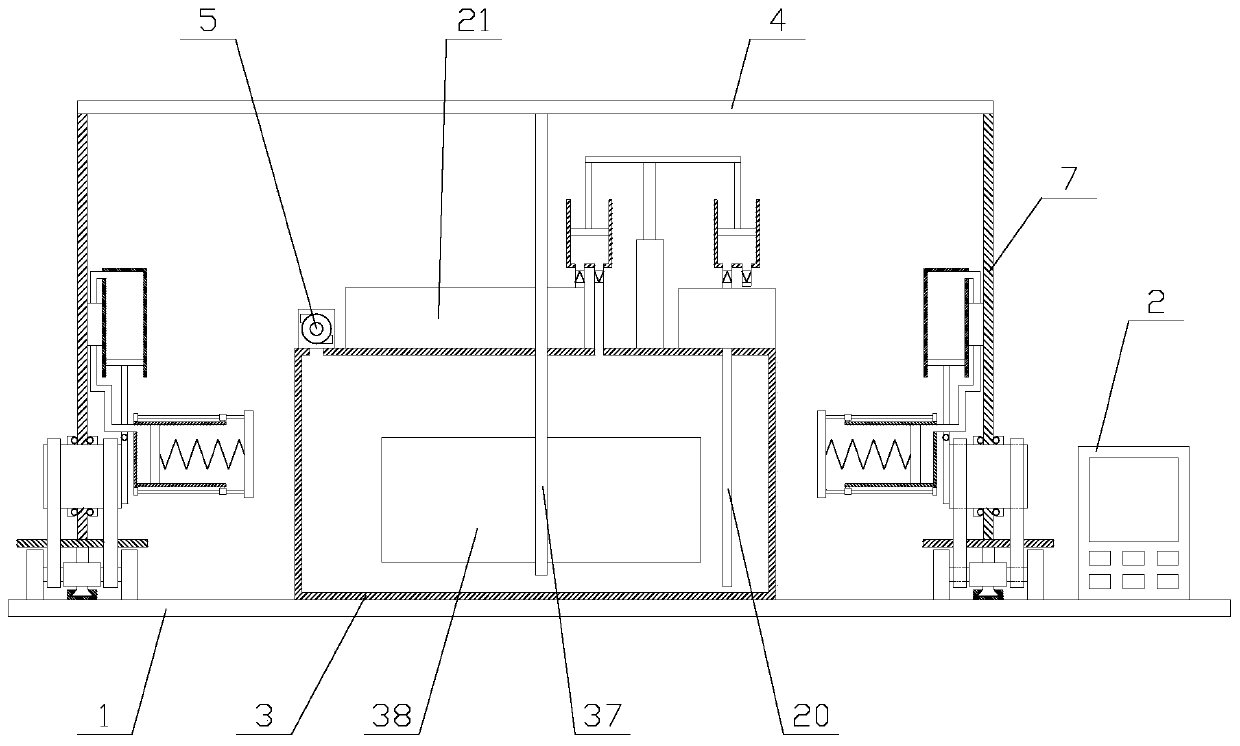

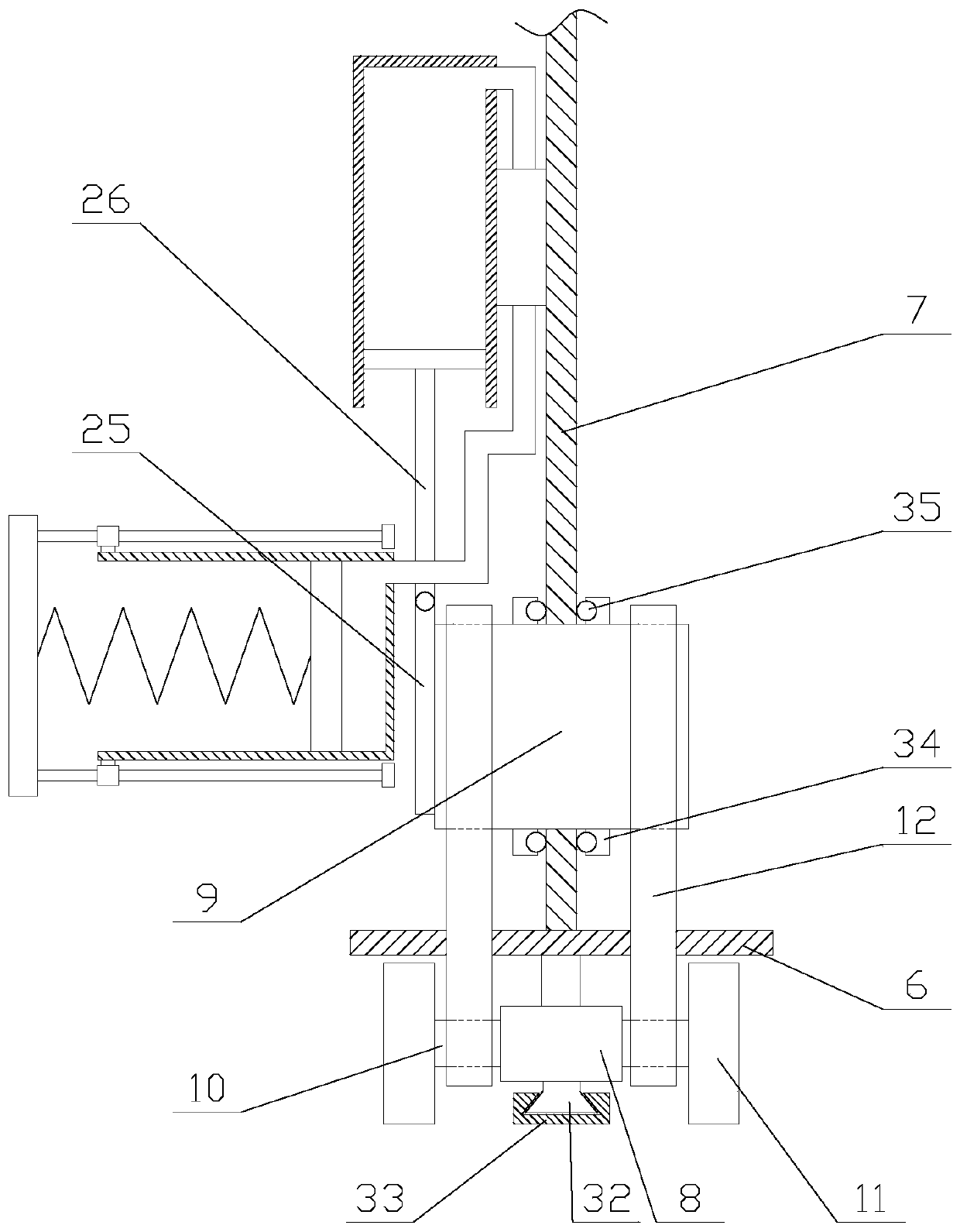

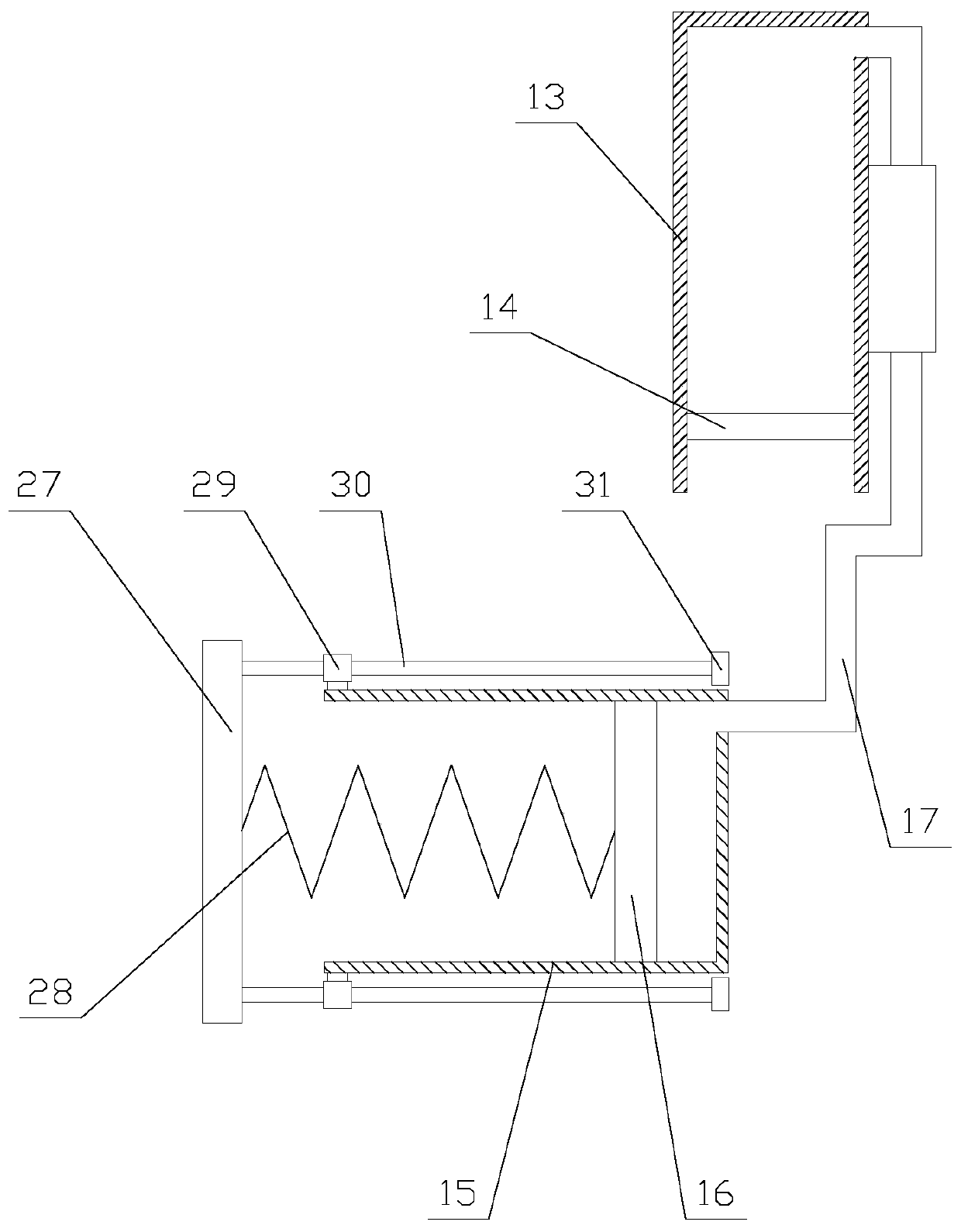

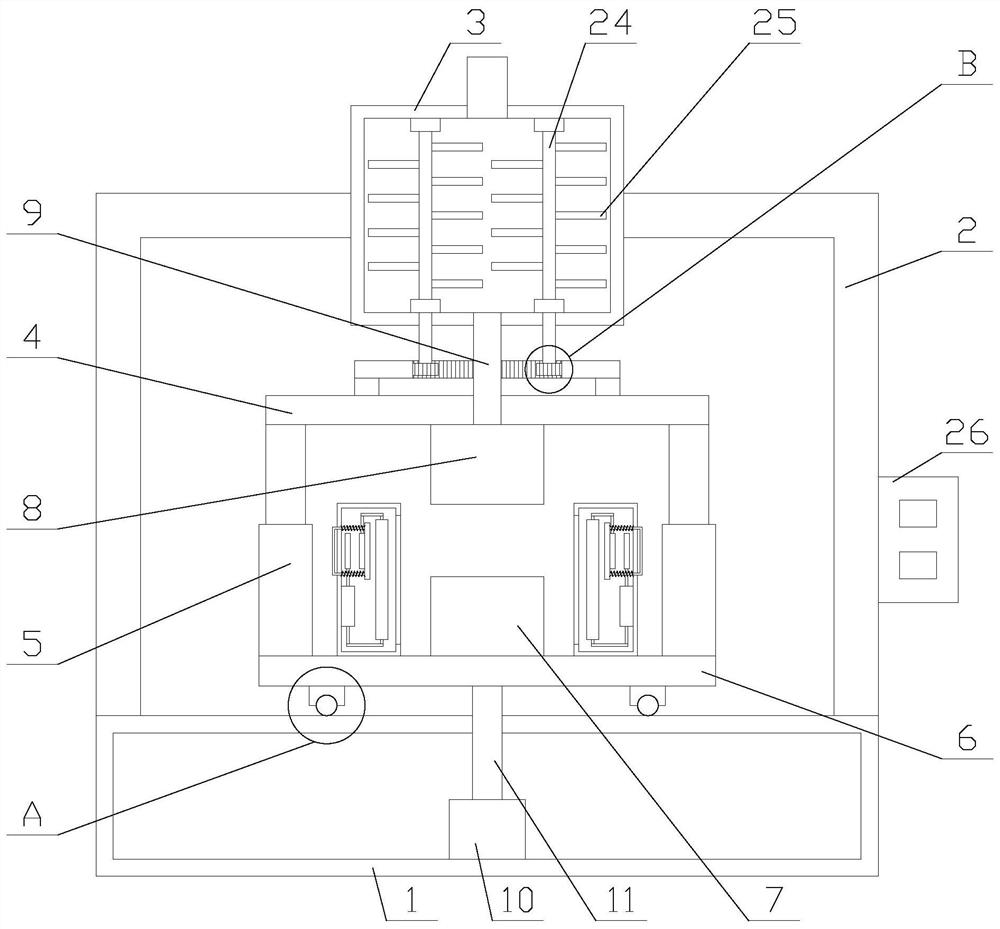

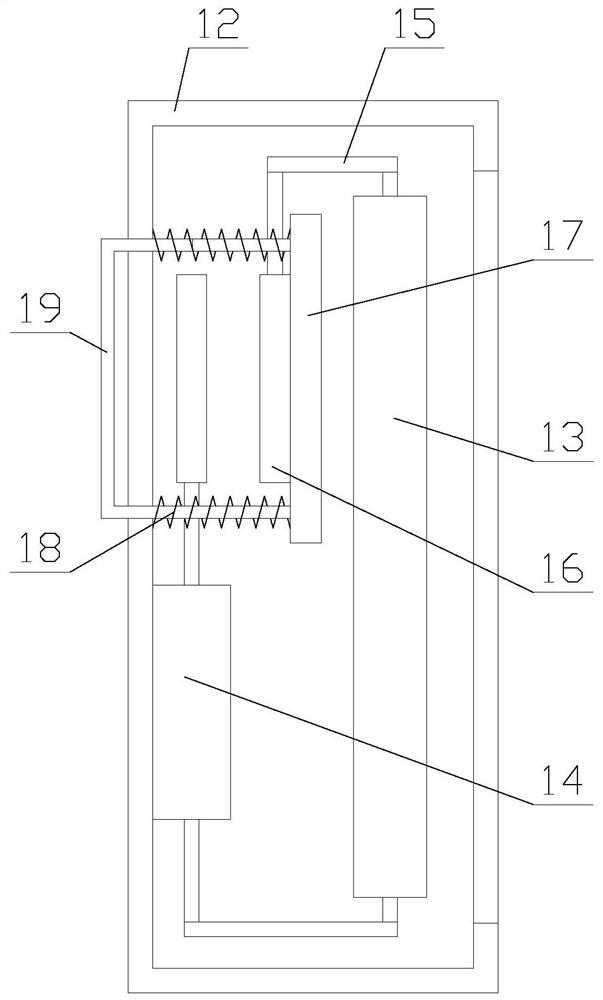

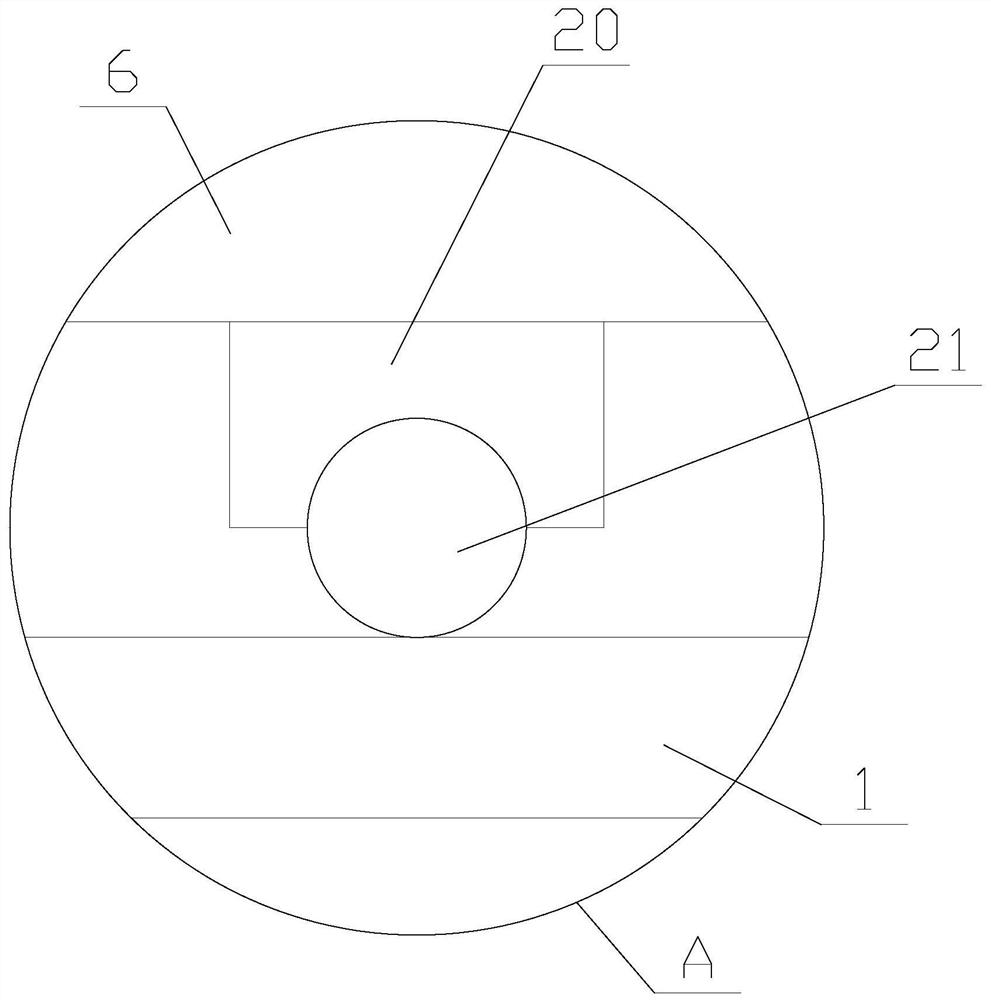

Steel drum film packaging thermal shrinkage treatment device and application method thereof

The invention relates to a steel drum film packaging thermal shrinkage treatment device and an application method thereof and belongs to the technical field of steel drum packaging. The thermal shrinkage treatment device comprises locating trays, a conveying device, a thermal shrinkage device, a hot air blowing device, a driving device, a baking device and a controller, wherein the locating traysare arranged on the conveying device; film packaged steel drums are arranged on the locating trays; the thermal shrinkage device is arranged above the conveying device; the hot air blowing device is arranged in the thermal shrinkage device; the thermal shrinkage device is connected with the driving device for driving the thermal shrinkage device to move up and down; the conveying device passes through the baking device; and the conveying device, the thermal shrinkage device, the hot air blowing device, the driving device and the baking device are connected with the controller. The steel drum film packaging thermal shrinkage treatment device achieves the technical effect that a film is attached to the steel drum closely, and no bubbles are generated in the plastic film packaging thermal shrinkage and fixing process of the plastic film packaged steel drum.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

Die-casting equipment for 5G automobile parts

Owner:广西润启互联网科技有限公司

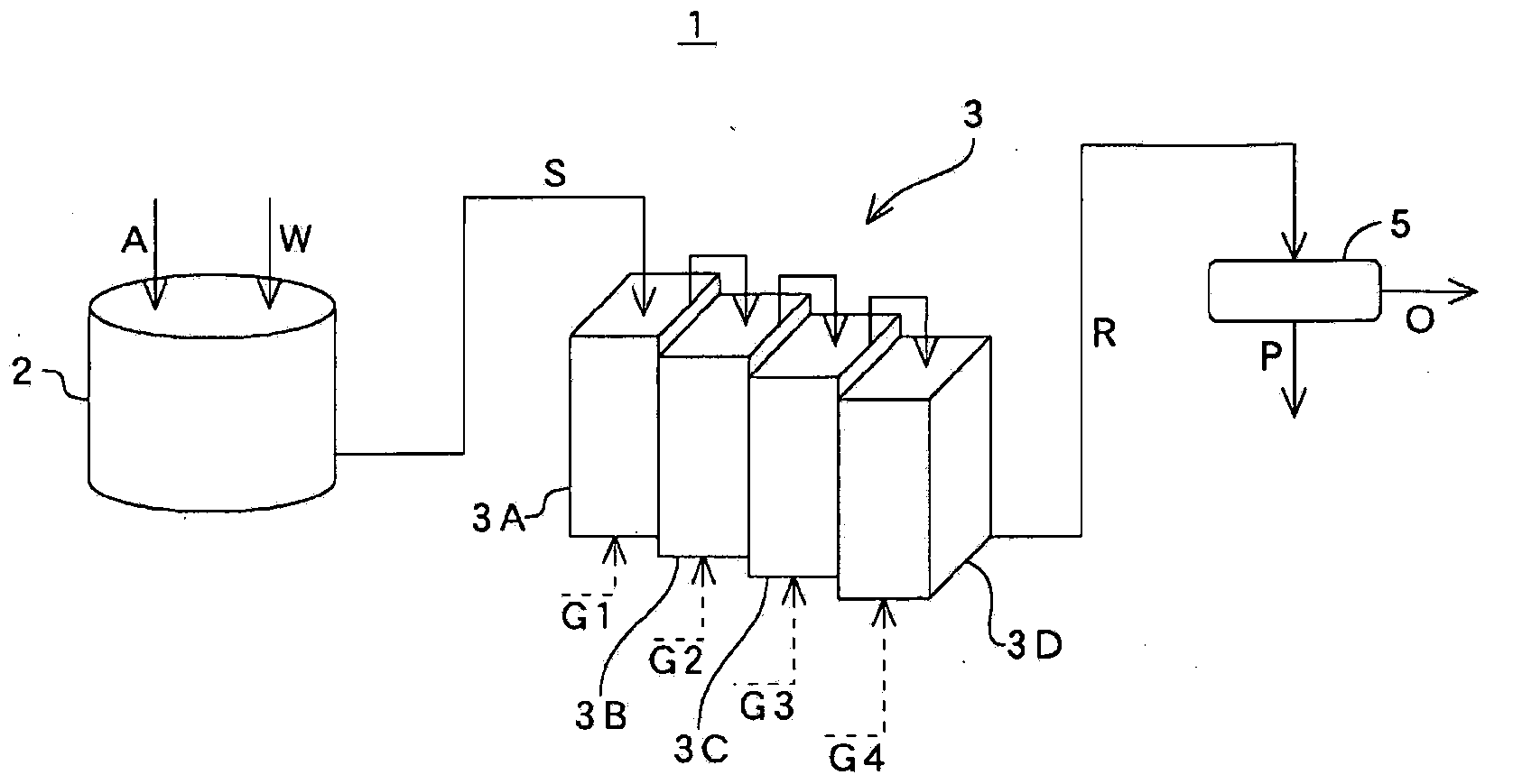

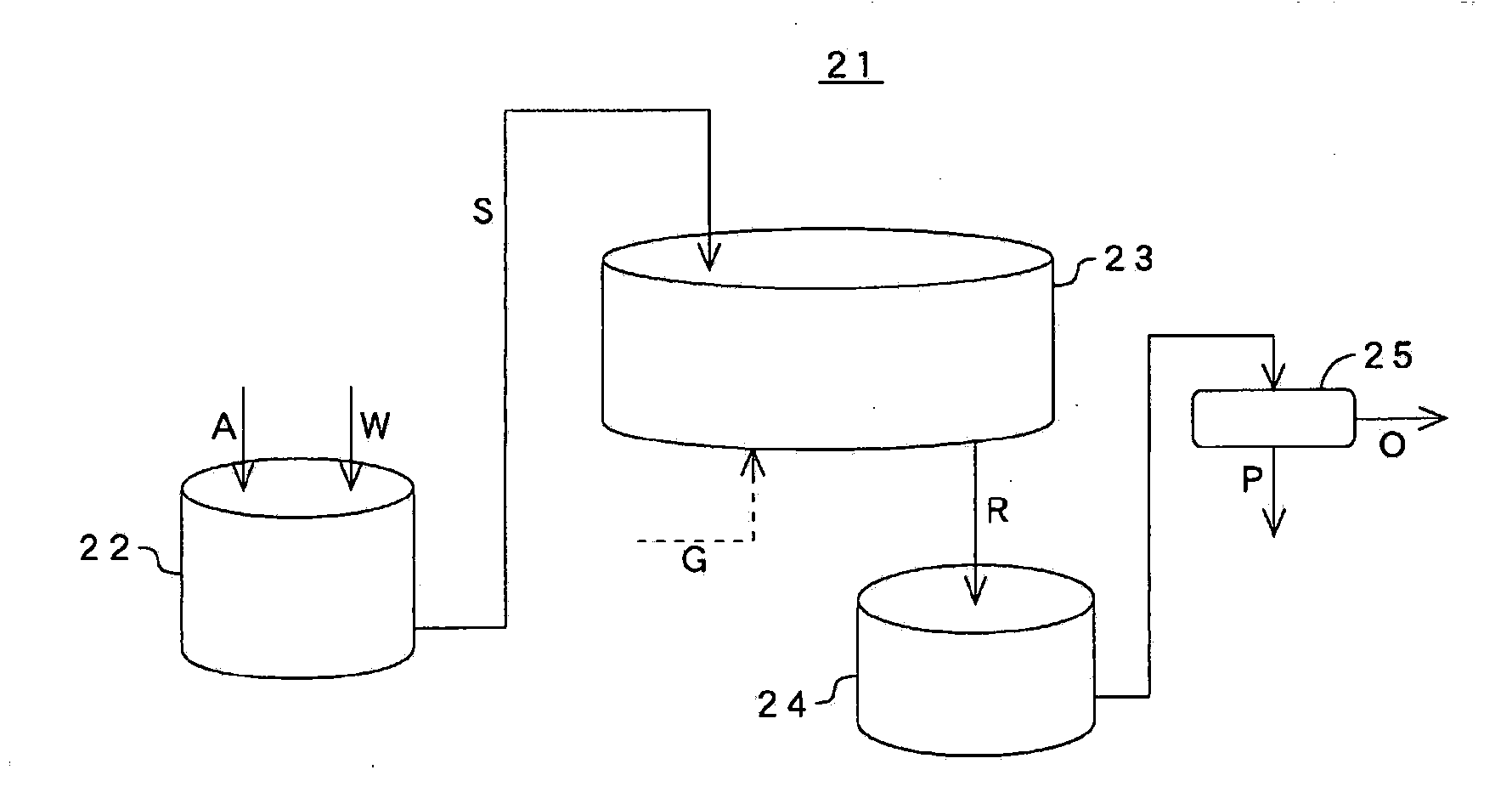

Continuous gas reaction device, and continuous dissolved gas reaction device

InactiveCN104203398AImprove processing efficiencyProhibition of useSolid waste disposalTransportation and packagingDissolutionSlurry

Owner:TAIHEIYO CEMENT CORP

Hydraulic casting equipment with defoaming function

Owner:广州市欧伊若科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap