Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Material transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transmitting layer depositing organic luminous display device

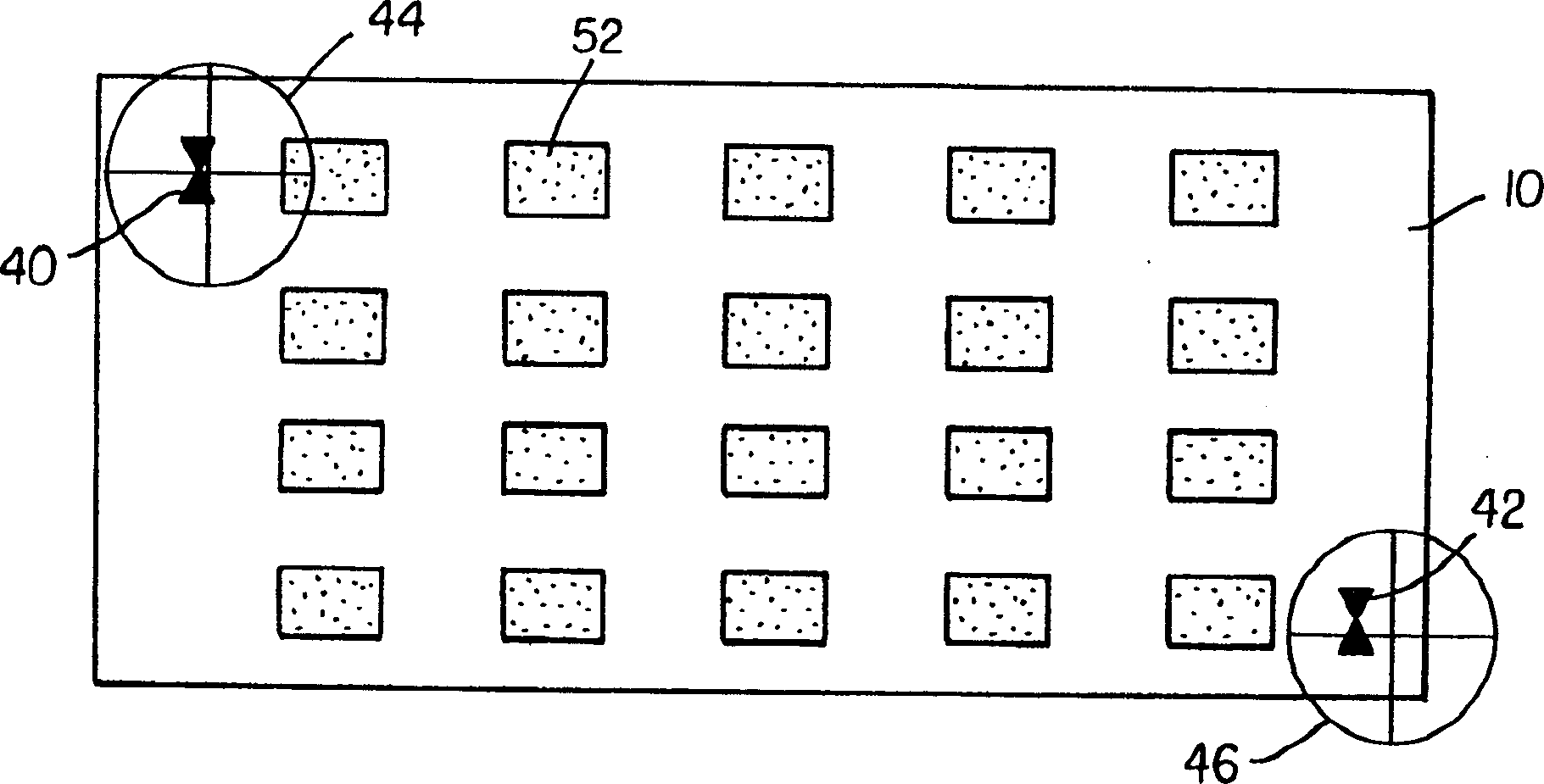

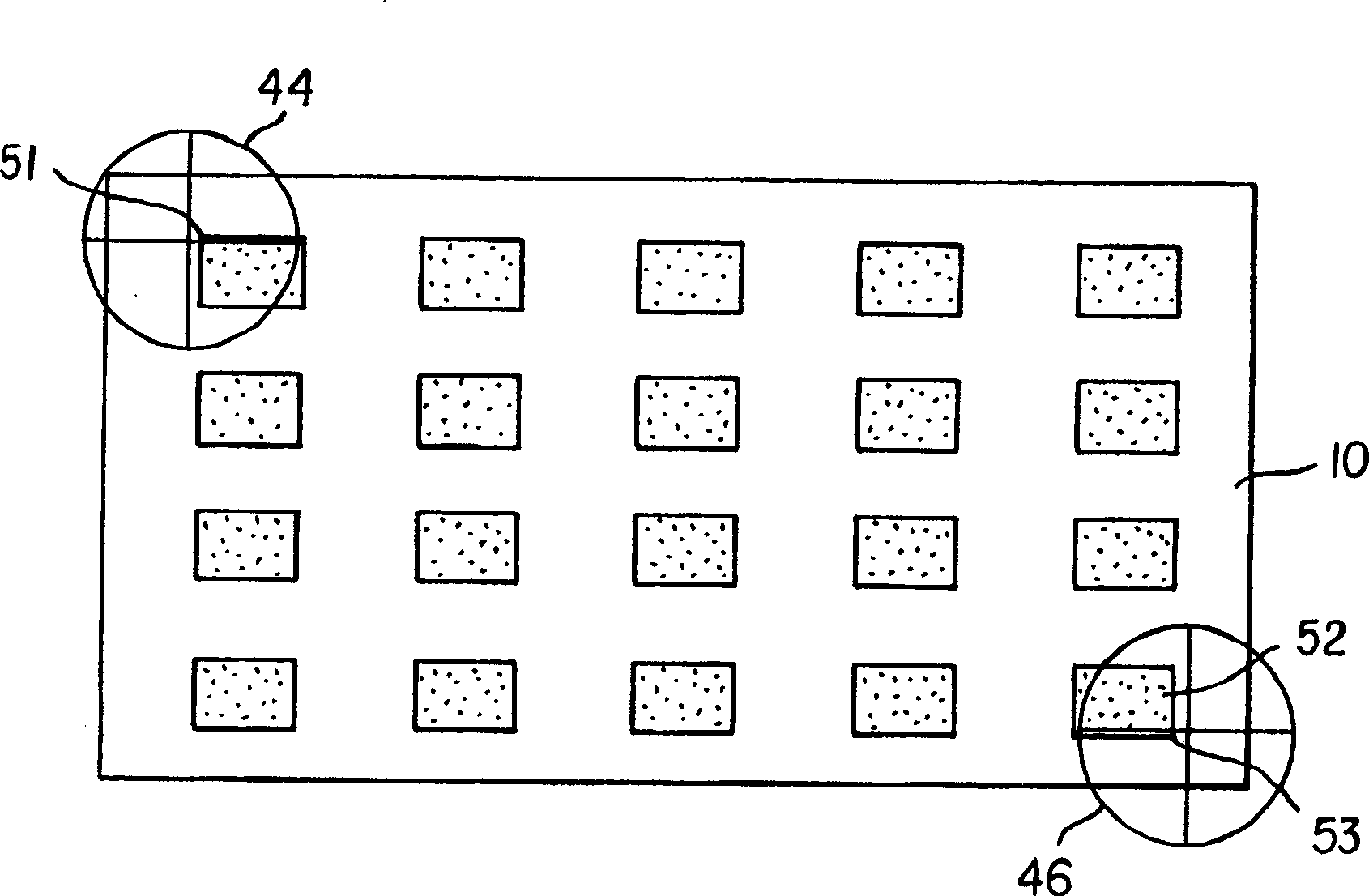

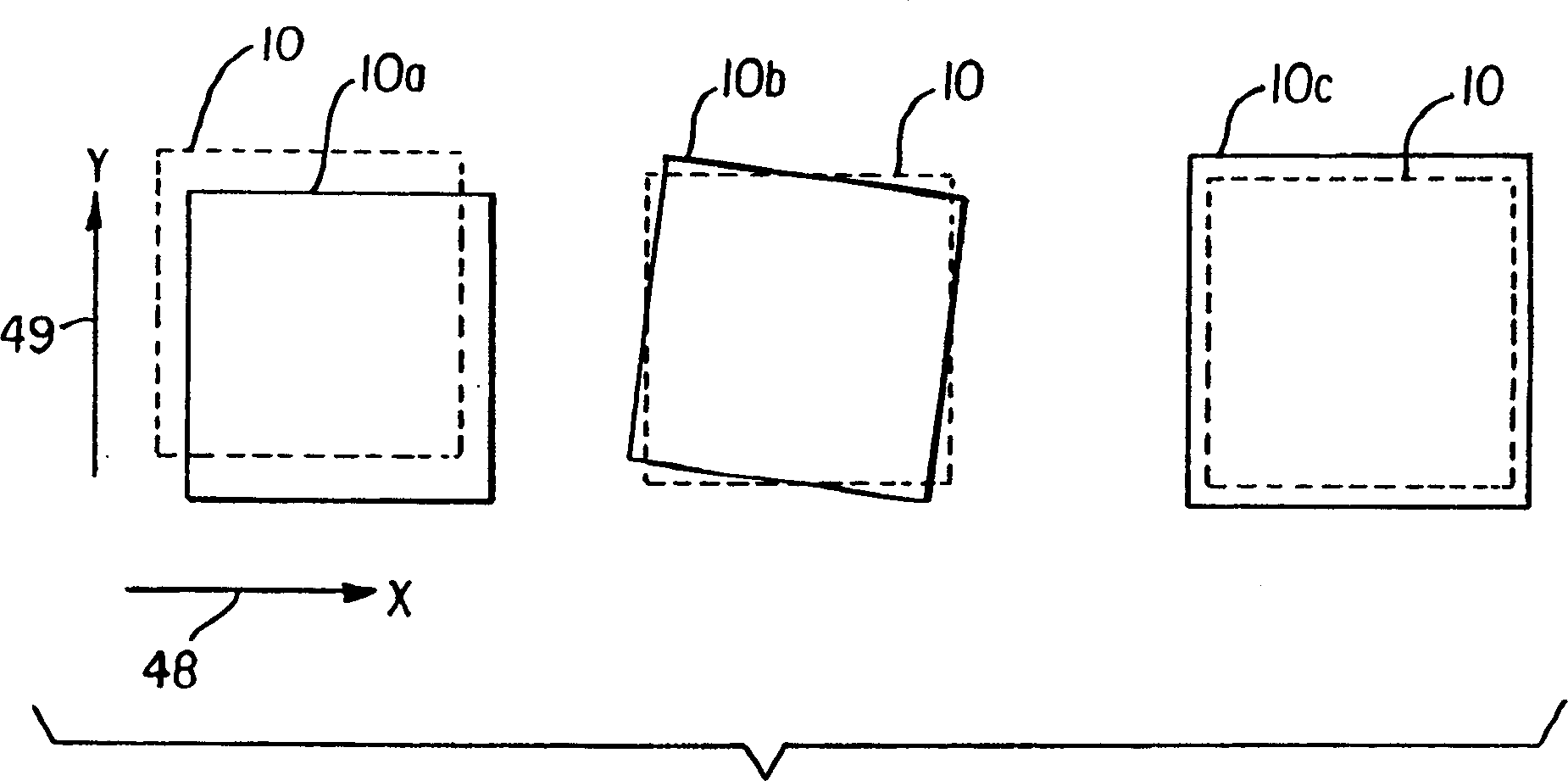

InactiveCN1471342AQuick and easy scalingIncrease productionSolid-state devicesElectroluminescent light sourcesGratingLight beam

Owner:EASTMAN KODAK CO

Full-automatic vacuum packaging unit for chicken feet

ActiveCN113928633ACreate pollutionAvoid artificial pollutionPackaging by pressurising/gasifyingChicken-clawsMaterial transfer

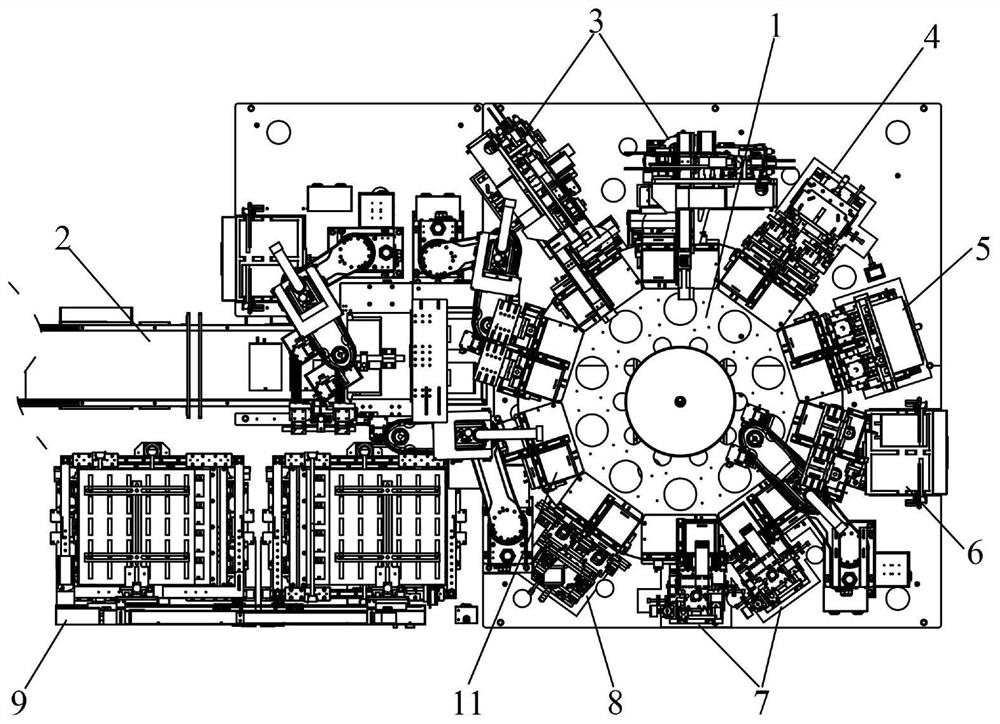

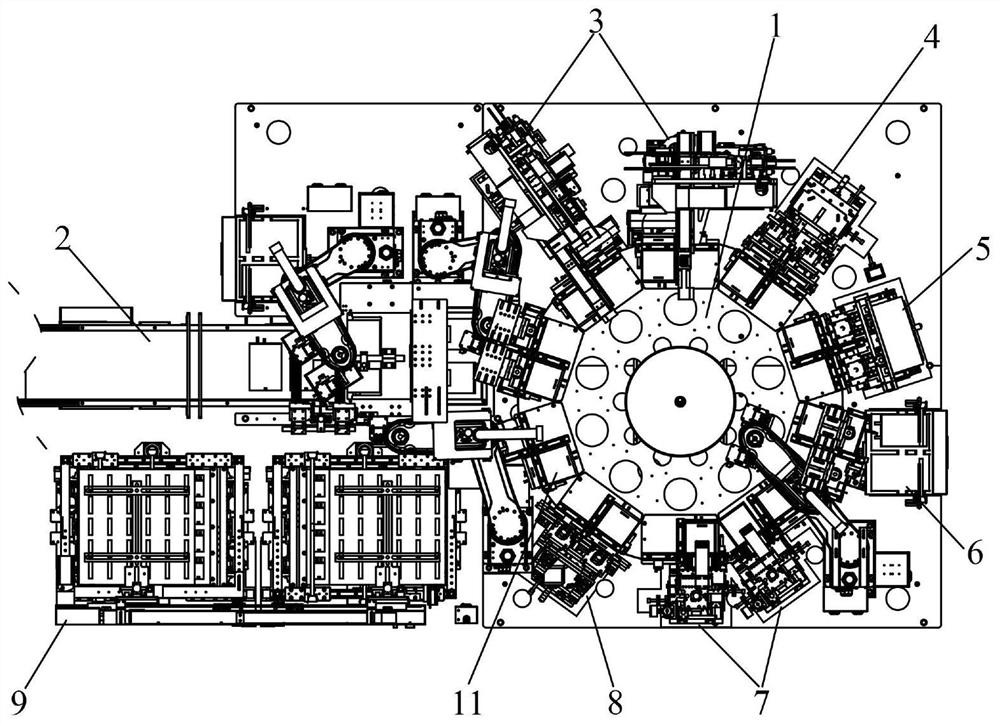

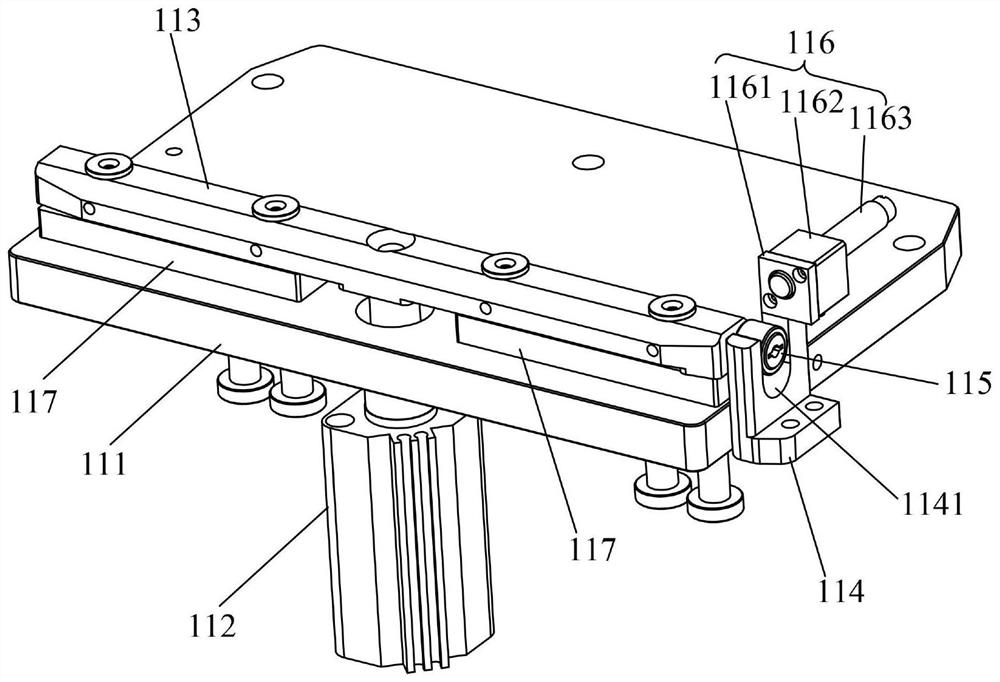

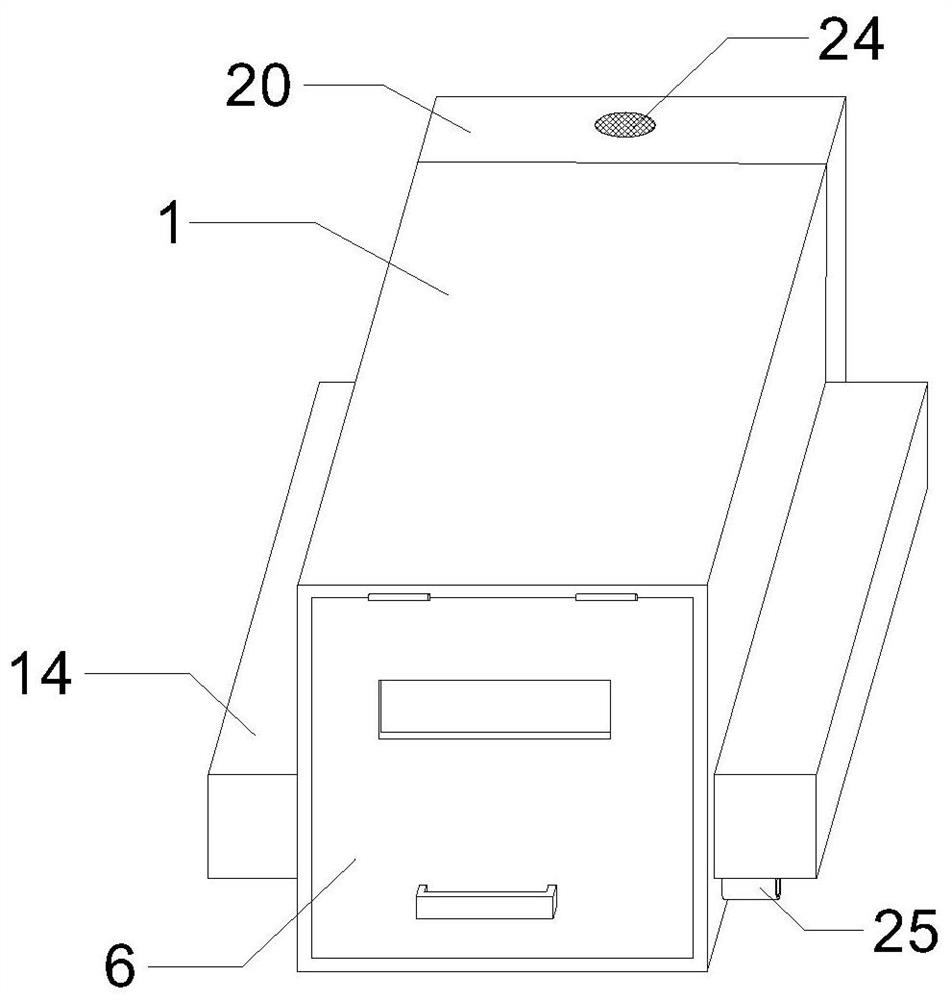

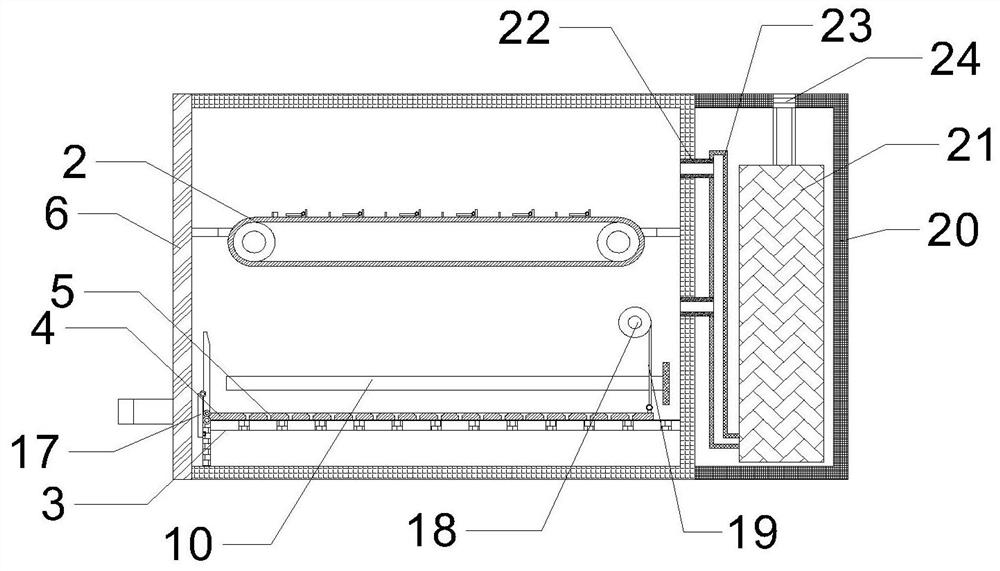

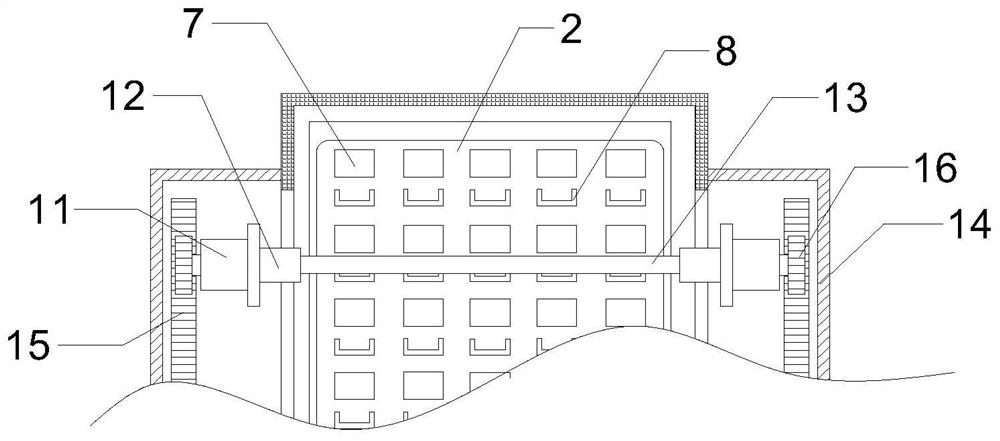

The invention discloses a full-automatic vacuum packaging unit for chicken feet, and relates to the field of food production. The full-automatic vacuum packaging unit comprises a supporting mechanism. A rotary material transferring mechanism is arranged at the top end of the supporting mechanism, a clamping and material conveying mechanism is connected to the top of the rear end of the supporting mechanism, and the clamping and material conveying mechanism is arranged at the front end of the top of the supporting mechanism. A material filling mechanism is arranged on the right side of the clamping and material conveying mechanism, and the rear end of the material filling mechanism is connected to the front end of the top of the supporting mechanism in a chain mode. A slitting mechanism is arranged at the bottom end of the material filling mechanism, a material filling and packaging mechanism is arranged at the top end of the material filling mechanism, and the material filling and packaging mechanism is arranged at the front end of the top of the supporting mechanism. The supporting mechanism comprises a supporting table. The bottom end of the supporting table is fixedly connected with a plurality of supporting bases, and the rear end of the supporting table is fixedly connected with a slitting connecting bracket in a chain mode. Meanwhile, when the full-automatic vacuum packaging unit is used, the rotary material transferring mechanism is arranged and cooperates with the clamping and material conveying mechanism in the feeding process, and therefore the pollution caused by manual errors to the filled chicken feet in the material conveying process is avoided.

Owner:ANHUI XIAOHU DUCK FOOD CO LTD

Automatic battery tail glue sticking and corner pressing machine

PendingCN113964366AReduce transfer processImprove machining accuracyPrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

Owner:东莞市爱康智能技术有限公司

Transfer equipment for waste lead-acid storage batteries and transfer method thereof

ActiveCN112644925AAvoid pollutionImprove stabilityRefuse receptaclesRefuse vehiclesProcess engineeringMaterial transfer

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap