Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Time changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

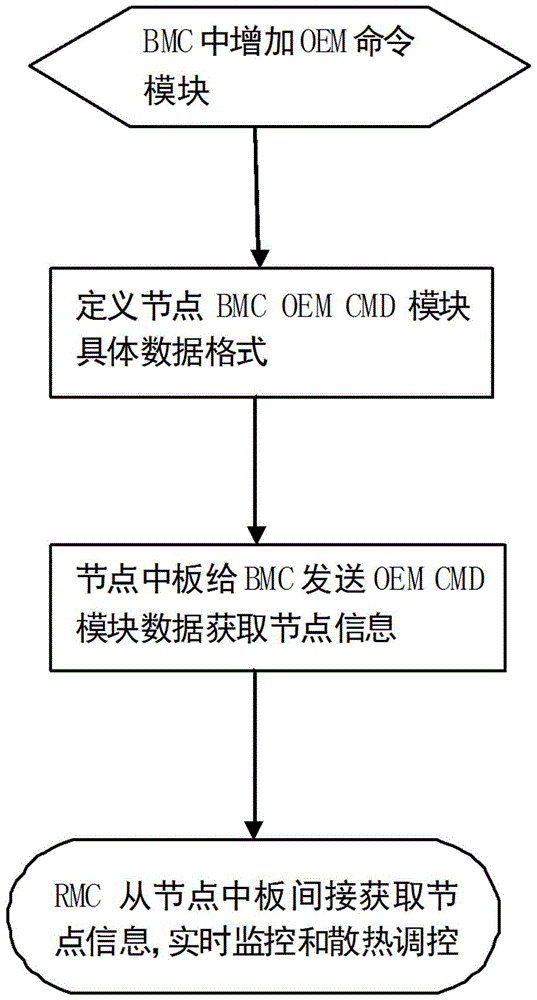

Method for obtaining monitoring information of complete cabinet server nodes

ActiveCN105868077ASimplify communicationQuickly adjust the speedHardware monitoringBaseboardTime changes

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

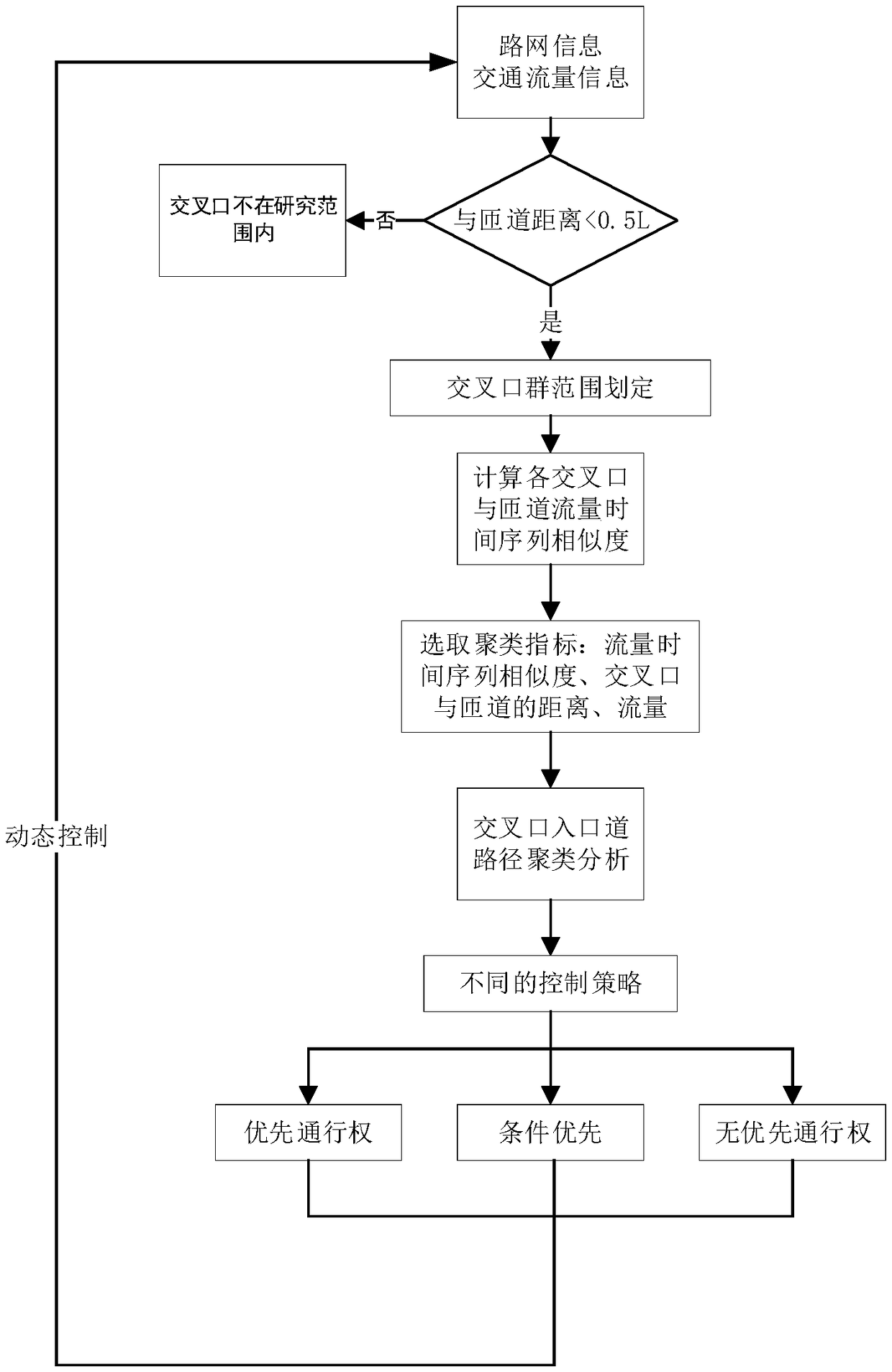

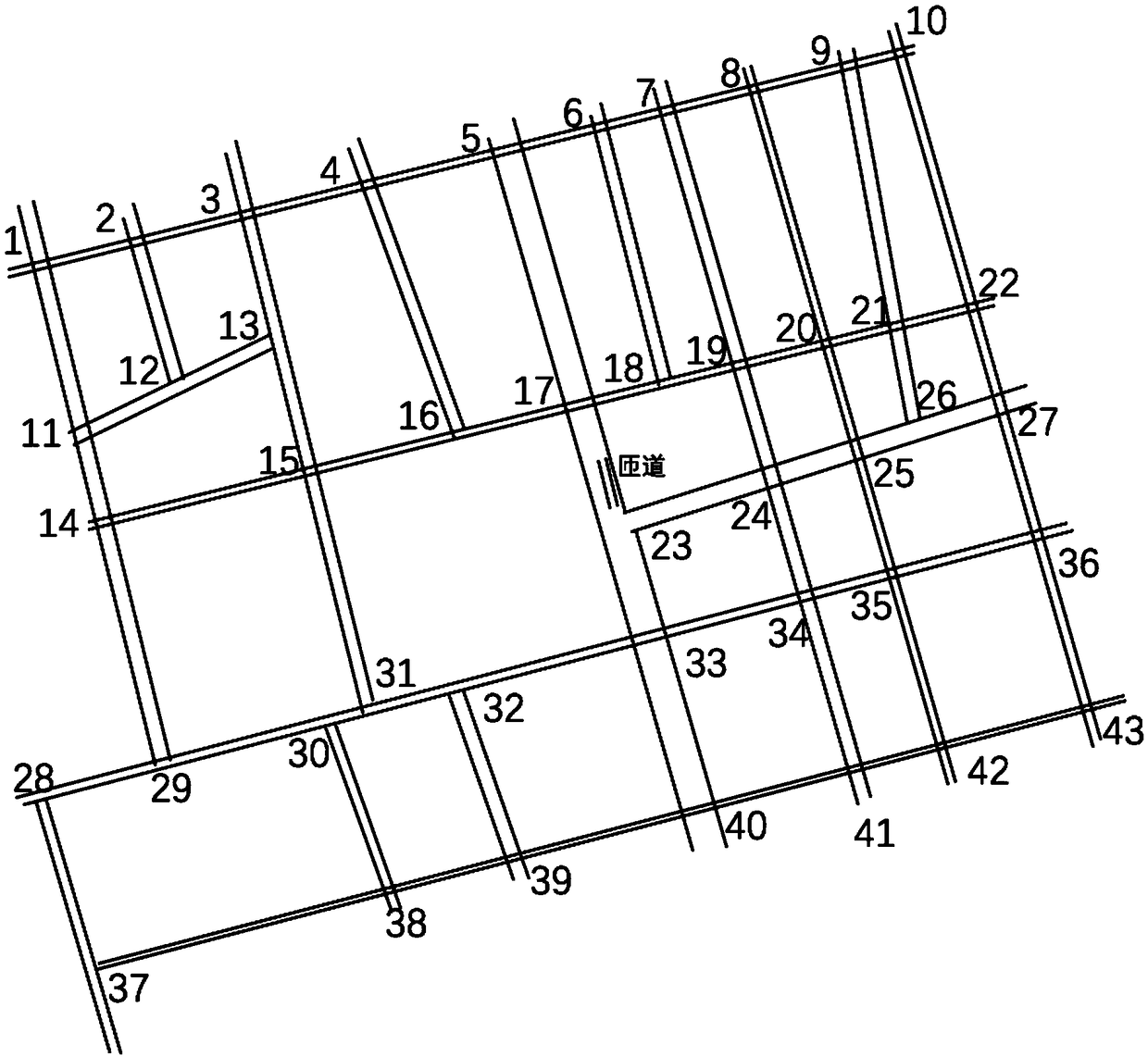

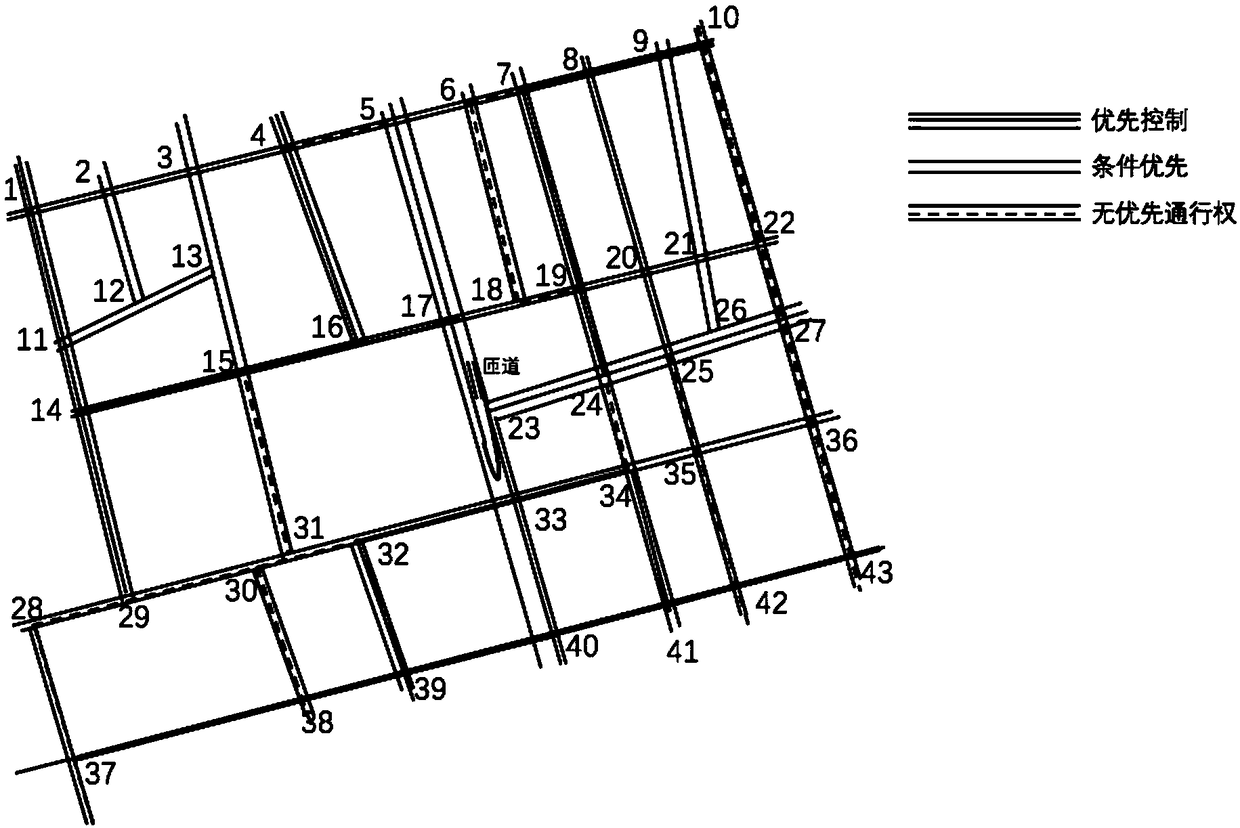

Path dynamic grading method of intersection group surrounding express way entrance ramp

ActiveCN108922174AControlling traffic signalsDetection of traffic movementTime changesTraffic volume

Owner:TONGJI UNIV

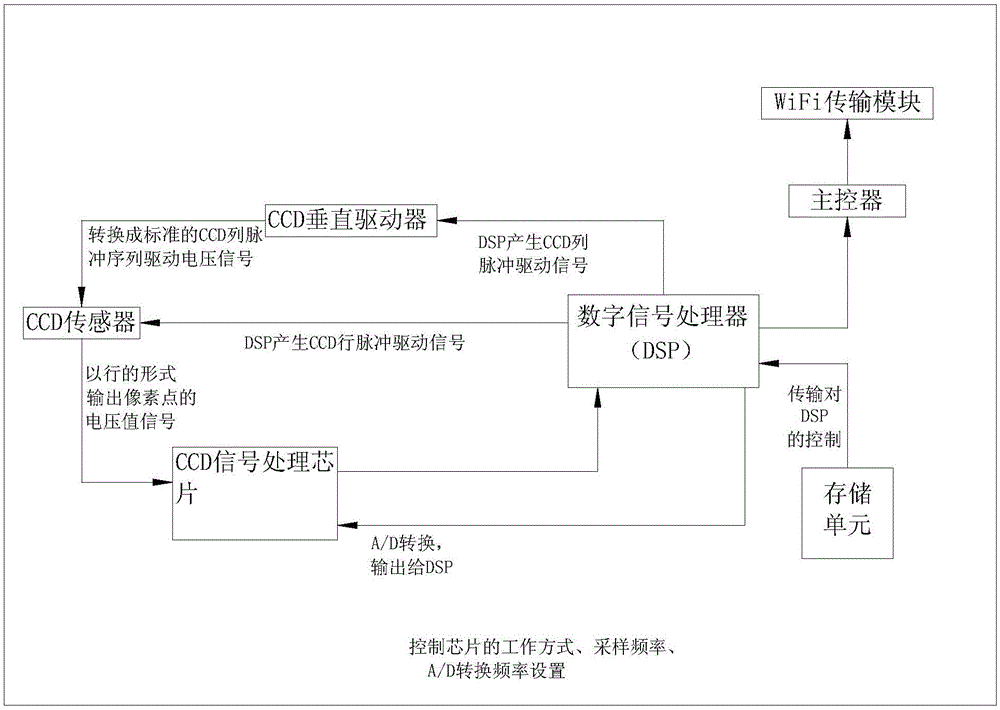

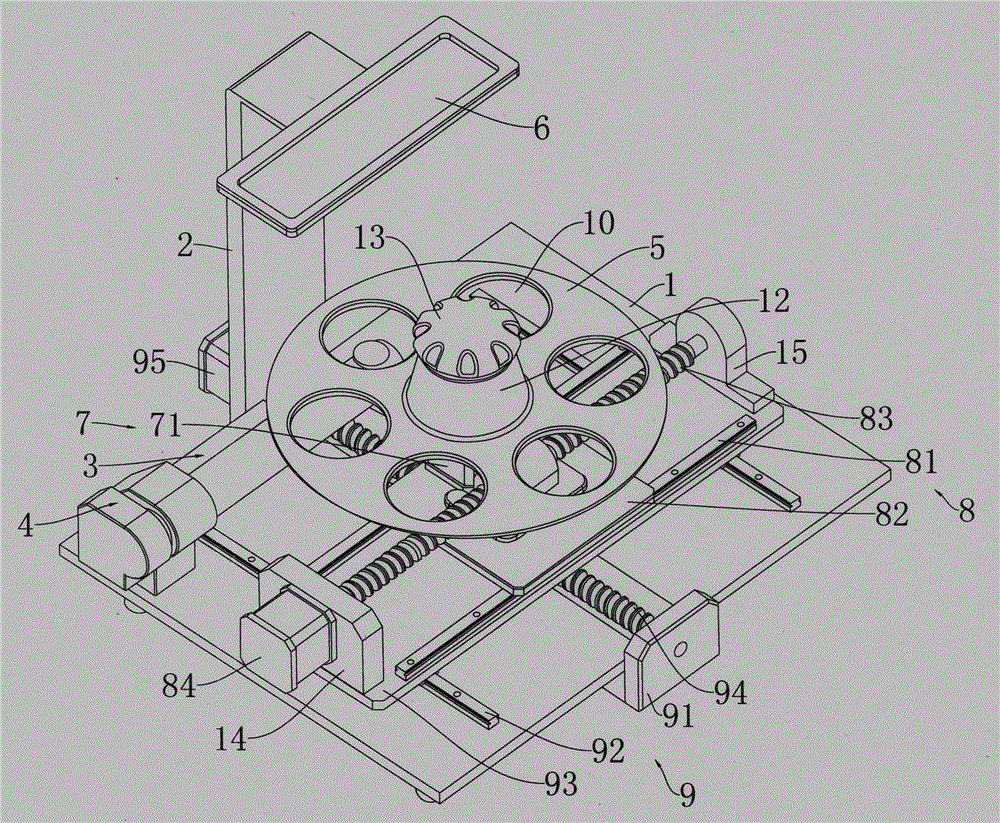

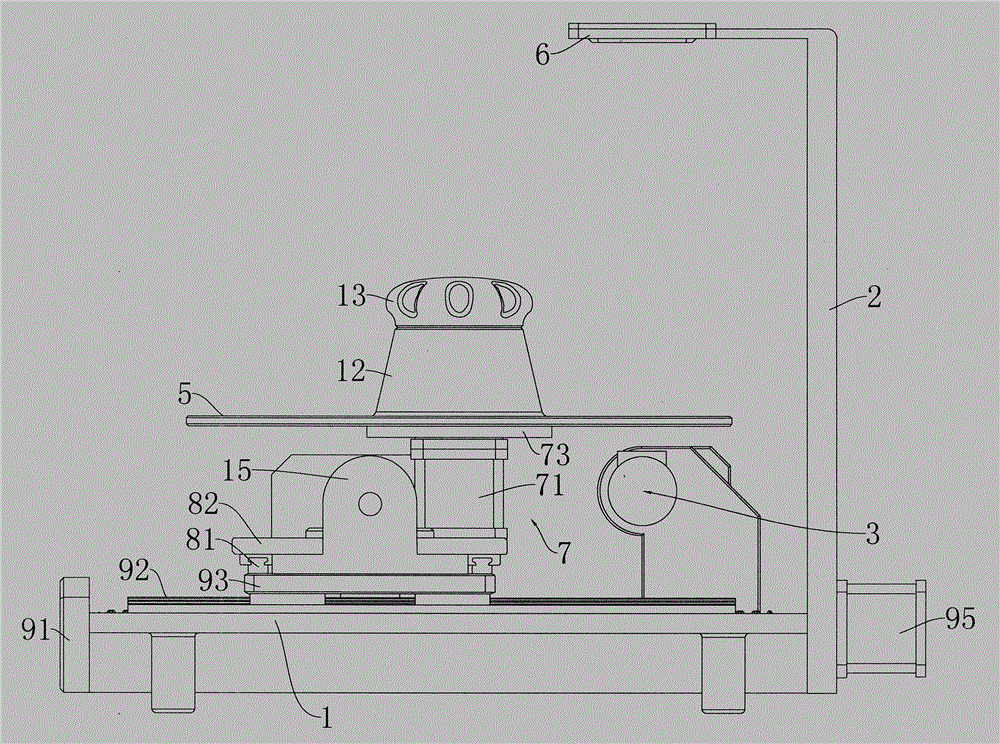

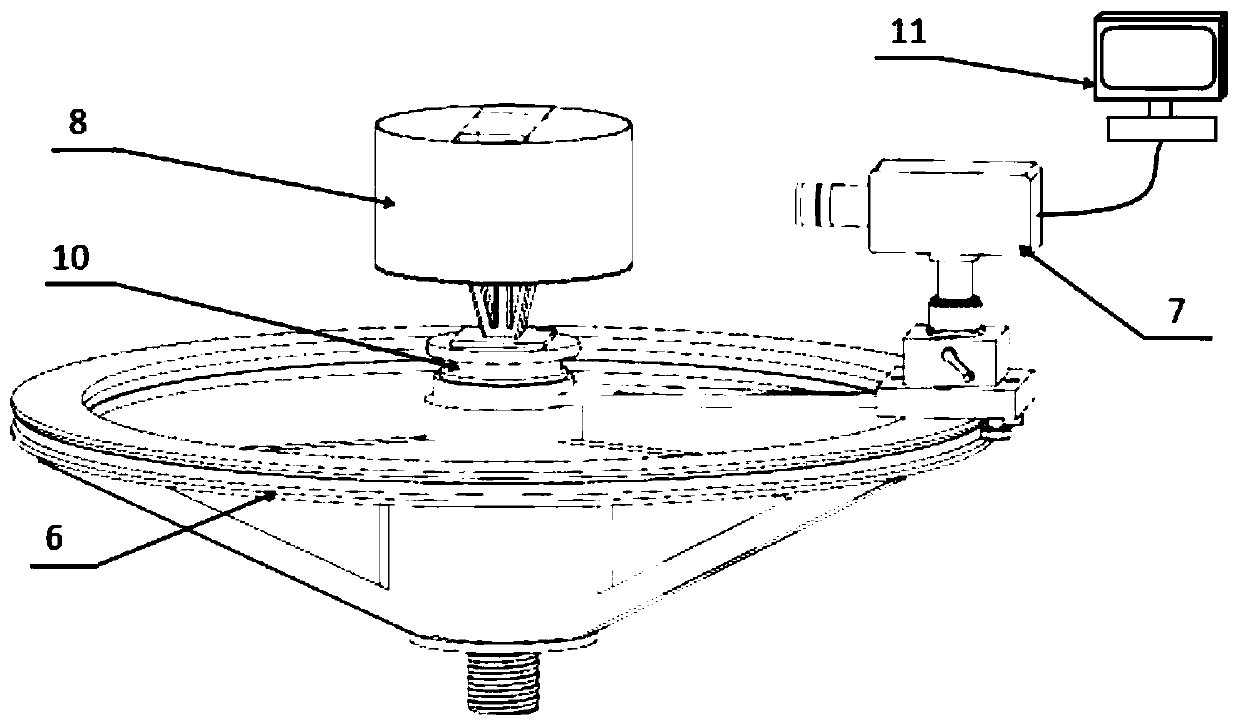

Network-based intelligent imaging analyzer for living cell culture in box

ActiveCN105136665ARealize the screenEnable mobilityMaterial analysis by optical meansRotary stageStudy observation

Owner:NINGBO JIANYI ELECTRONICS INFORMATION TECH CO LTD

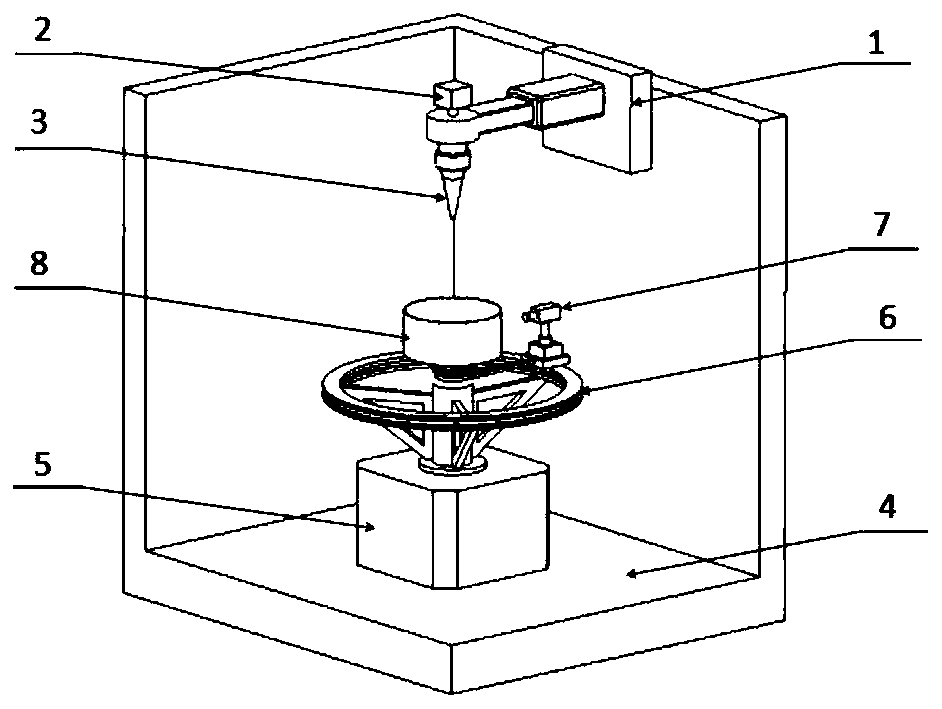

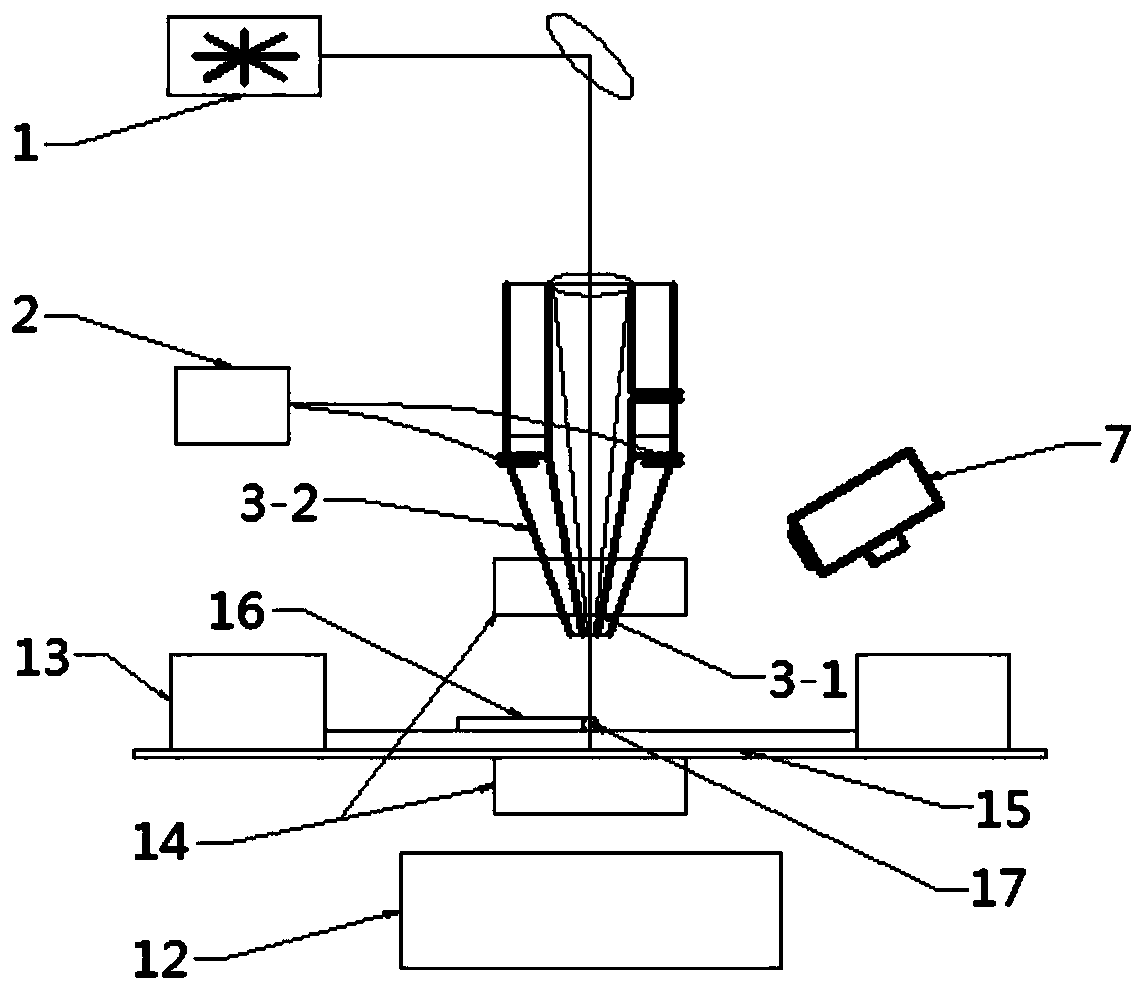

Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

InactiveCN110280904AWide range motion captureComprehensive perspectiveLaser beam welding apparatusUltrasonic assistedLaser Nozzle

Owner:JIANGSU UNIV

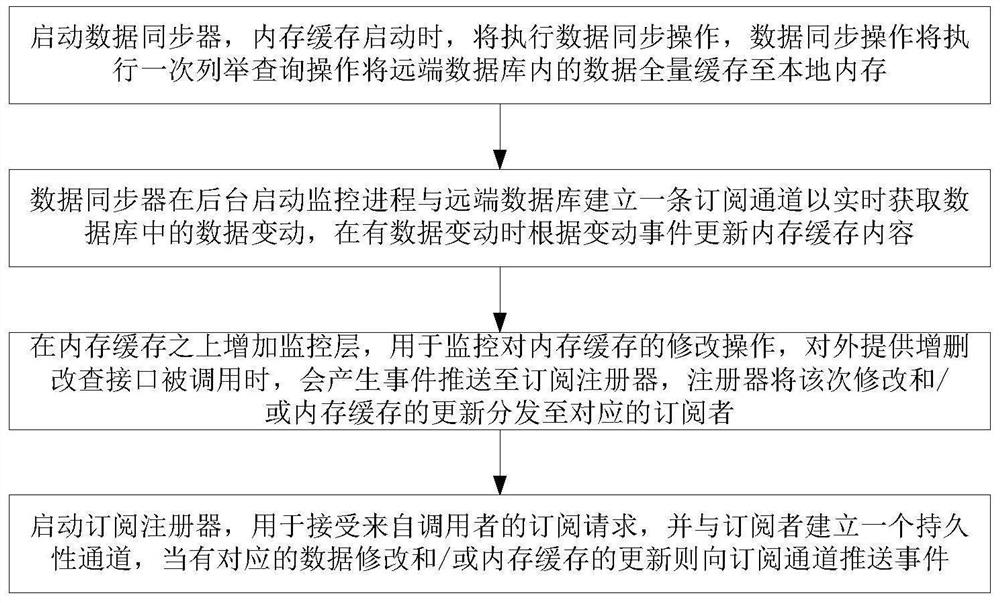

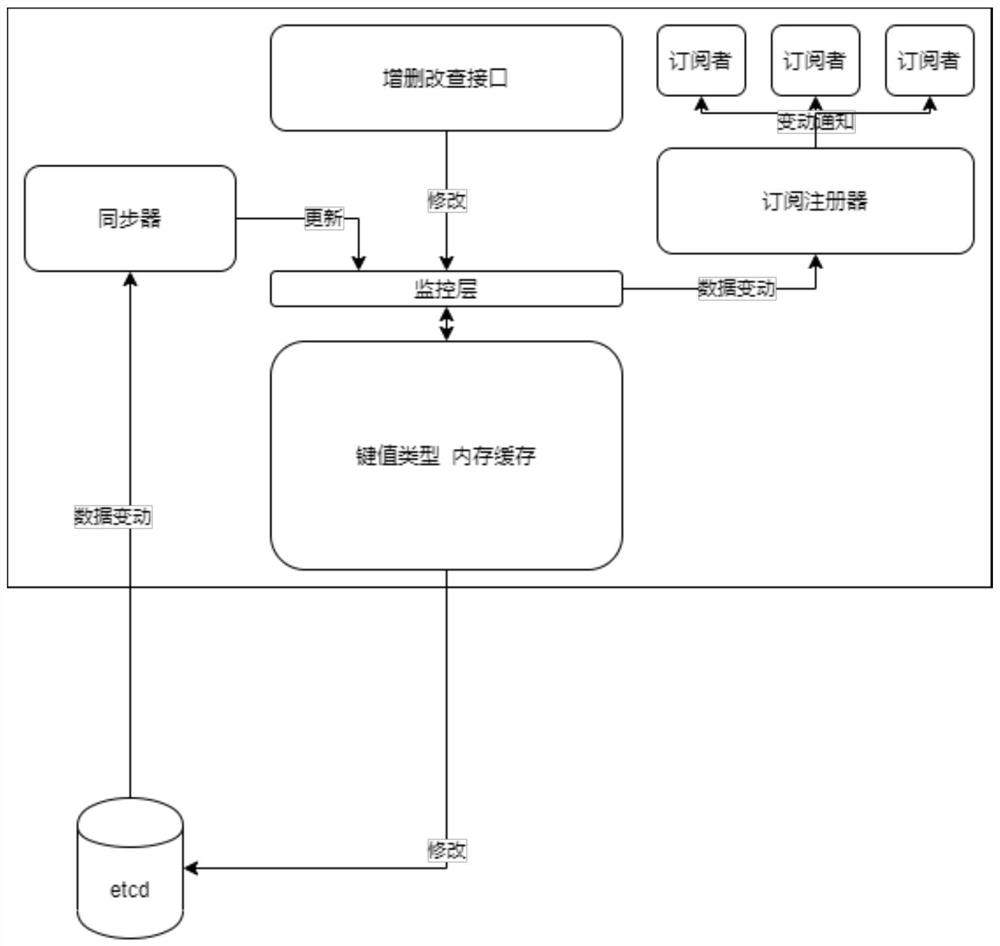

Cache system and method supporting real-time change notification and real-time data synchronization

Owner:成都精灵云科技有限公司

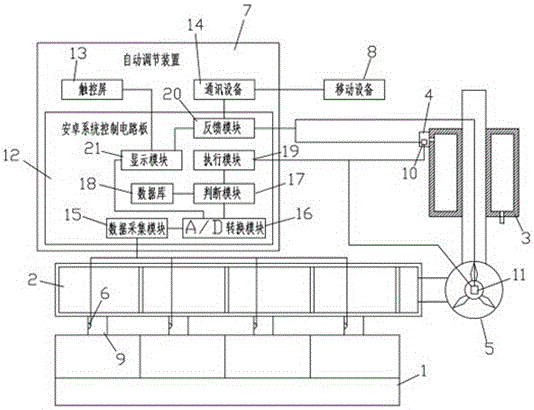

Setting machine exhaust gas processing equipment energy consumption automatic adjusting system

InactiveCN106647864AChange speed in real timeControl consumptionTemperatue controlFrequency changerCommunication device

Owner:SUZHOU GUANGSHENG ENVIRONMENTAL TECH CO LTD

Moving image processing apparatus and reproduction time offset method

InactiveUS20100202756A1Television system detailsPicture reproducers using cathode ray tubesImaging processingMotion vector

A moving image processing apparatus comprises a moving image encoder which outputs the motion vectors of an encode frame, a reproduction time changing unit which, on the basis of the motion vectors, determines a motion quantity between a moving image frame with the motion vectors and the preceding moving image frame and calculates an offset for a reproduction time, a reproduction time generating device which generates a reproduction time of a target frame from a reference time and the offset for the reproduction time, and a reproduction time adding device which adds the reproduction time generated at the reproduction time generating device to moving image data output and encoded by the moving image encoder.

Owner:KK TOSHIBA

Quantitative aflatoxin distinguishing method by using quantitative change of chemical constituents

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap