Pile-forming method of immersed tube pile

A sinking pile and pile-forming technology, which is applied in the pile-forming field of sinking piles, can solve problems such as difficult quality assurance, large bearing capacity at the loss end, and attenuation of bearing capacity, and achieve quality and safety improvement, strict quality requirements, The effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

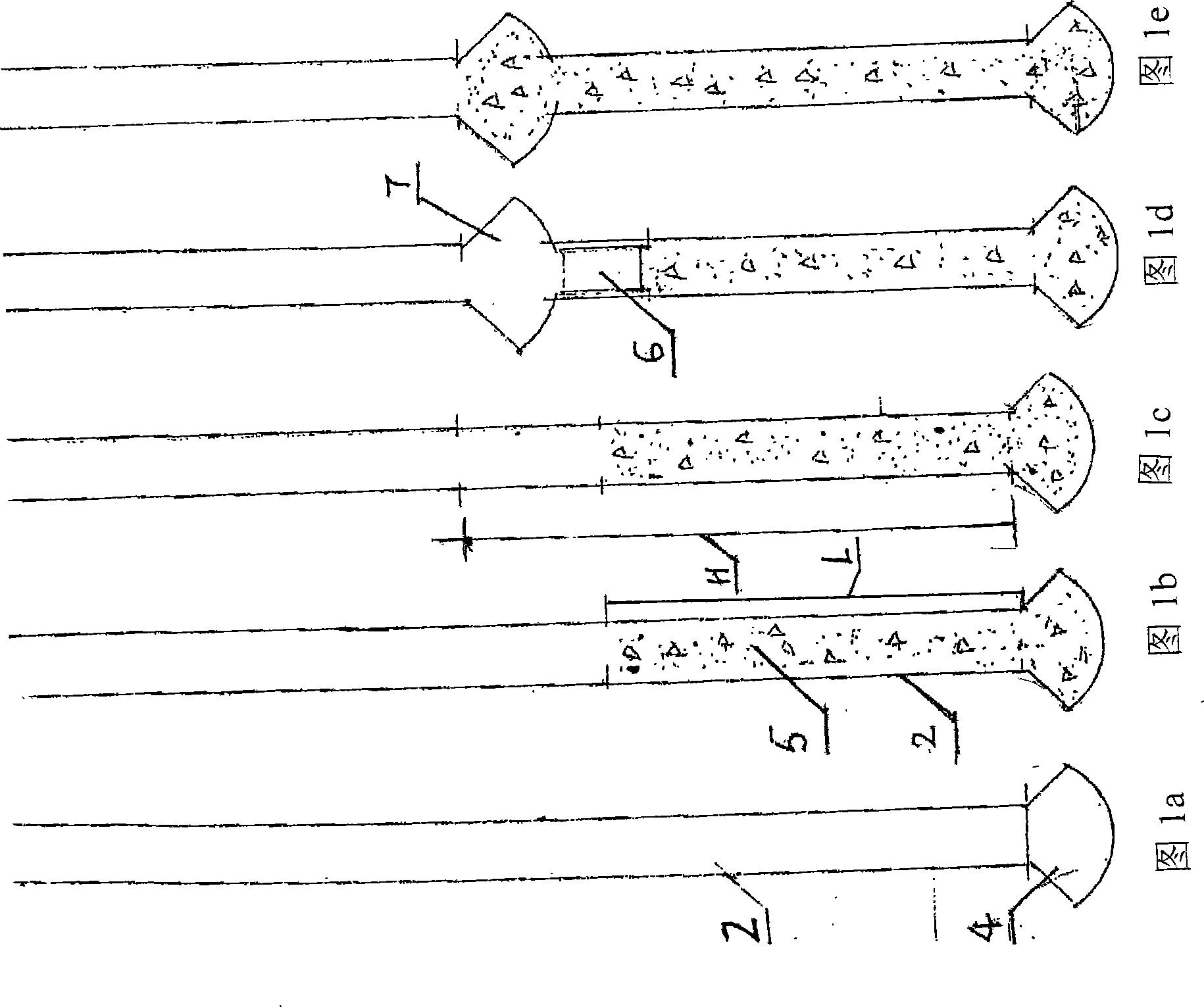

[0014] Embodiments of the present invention are described in detail with reference to Figures 1a-1g.

[0015] The pile-forming method of the sinking tube secondary expansion bottom pile of the present invention comprises the following process steps: a, sinking the sinking tube 2 with the metal pile head into the design elevation of the hard soil layer; b, taking out the metal pile head; Put emulsified oil or ammonium antimony explosive into the nozzle, every 0.5m 3 The dosage is 1-5 kg. After the explosive is detonated, the mouth of the immersed tube is sealed. After the explosion of the explosive is completed, the article that seals the mouth of the immersed tube is opened to take clean broken soil, and the bottom of the bottom is expanded with mechanical bottom expansion equipment to form the lower base space 4. The excavated crushed soil; d, put the flowing concrete 5 from the immersed tube mouth to the set height L, and its L is equal to the distance from the height of the up

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap