Device and method for non-underwater concreting by using drilled pile

A technology of pouring concrete and bored piles, which is applied in construction, foundation structure engineering, etc., can solve the problems of increasing the weight of the pile foundation, entering into the concrete, and complicated operation, so as to save the cost of detection and treatment, and the concrete structure is dense and The effect of simplification of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

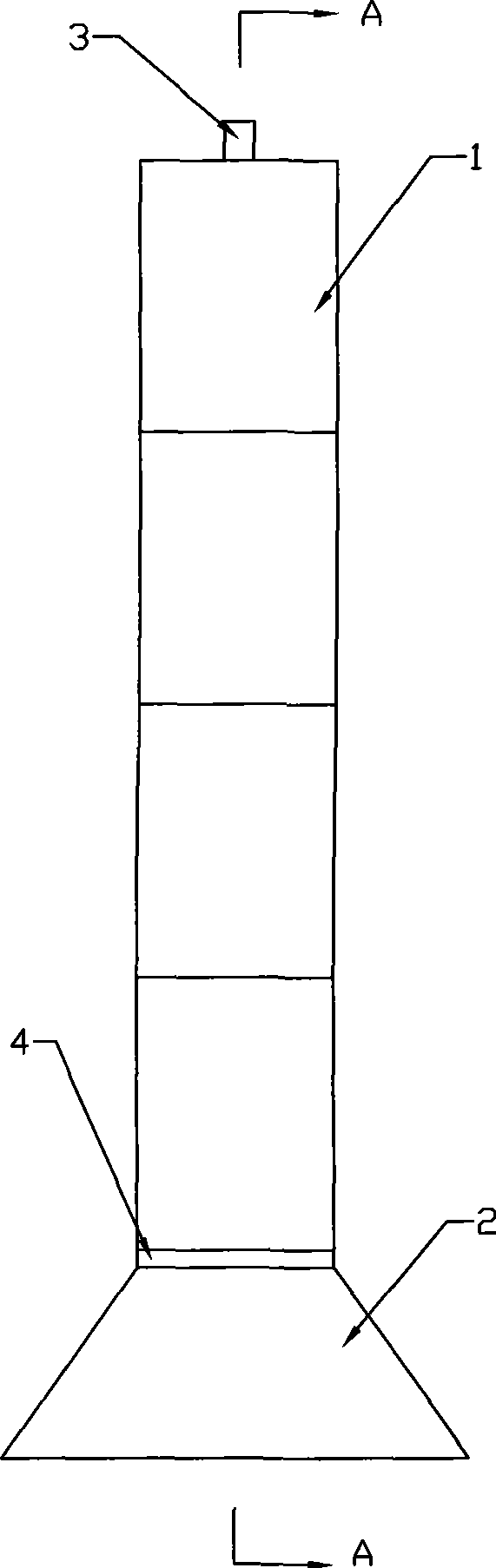

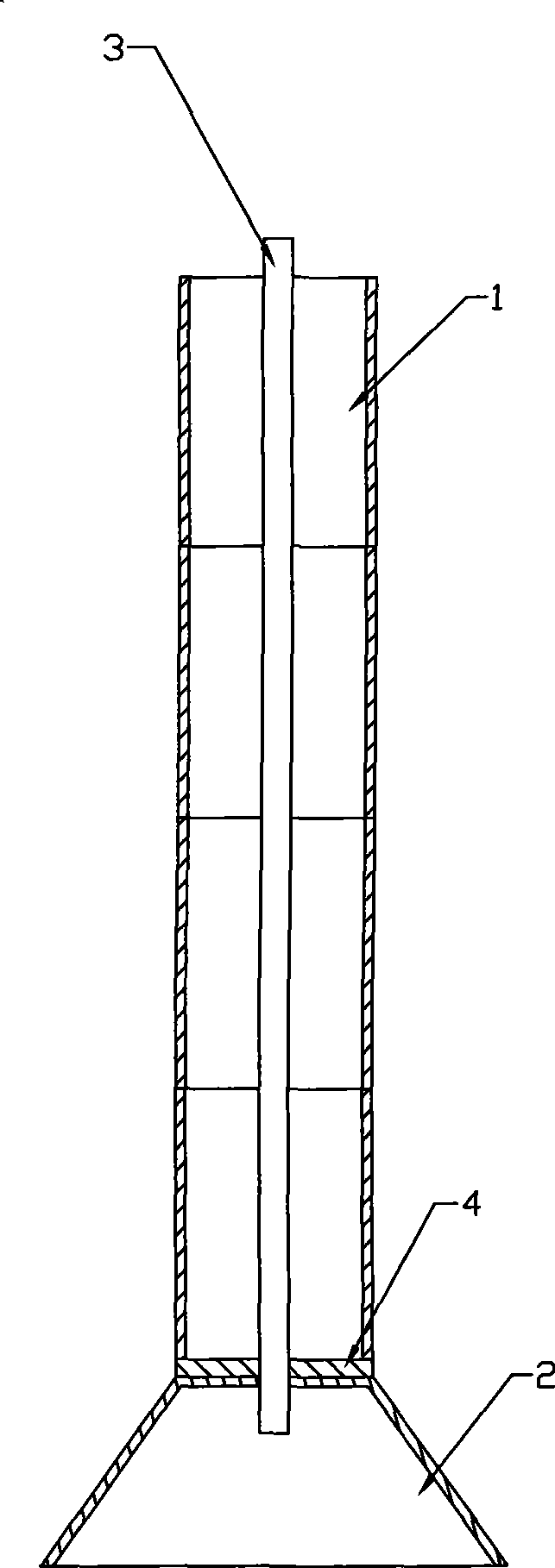

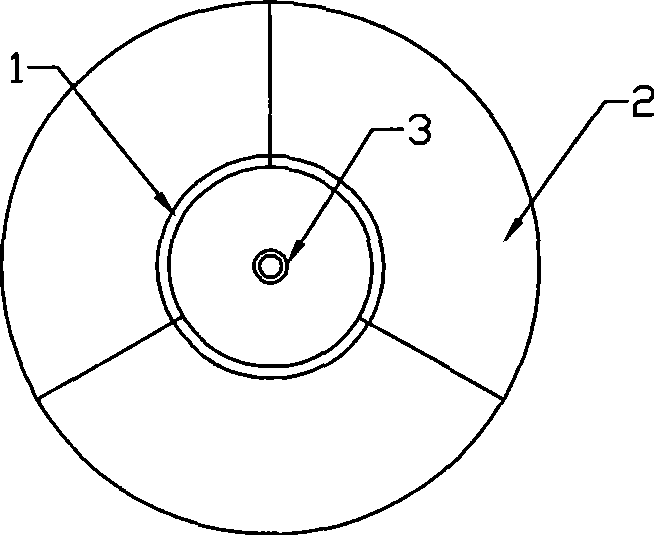

[0042] The method for non-submerged concrete pouring of bored piles as shown in Figures 4 to 6 is the second embodiment of the present invention, which includes the steps in the following order:

[0043] (1) First, lift the device connected by the drain pipe 3, the inner mold unit 1, the sealing cover 4 and the pipe shoe 2 to the opening of the drilled hole, and connect the upper end of the drain pipe 3 to the pumping device (not shown in the figure) ;

[0044] (2) a funnel 5 that is adapted to the inner mold unit and the borehole orifice is installed on the inner mold unit, and the reinforcement cage 6 is set between the outer wall of the inner mold unit and the inner wall of the drilled hole before starting to pour concrete; Then start the water pumping device and pour concrete 7 into the space between the outer wall of the inner mold unit and the inner wall of the borehole while lowering, and at the same time, the same volume of water 9 is discharged from the drain pipe; when

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap