Method for producing photocatalysis ceramics with adjustable surface gloss

A technology of photocatalytic ceramics and production methods, applied in chemical instruments and methods, physical/chemical process catalysts, titanium dioxide, etc., can solve problems such as gloss changes, achieve consistency, ensure decorative effects, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

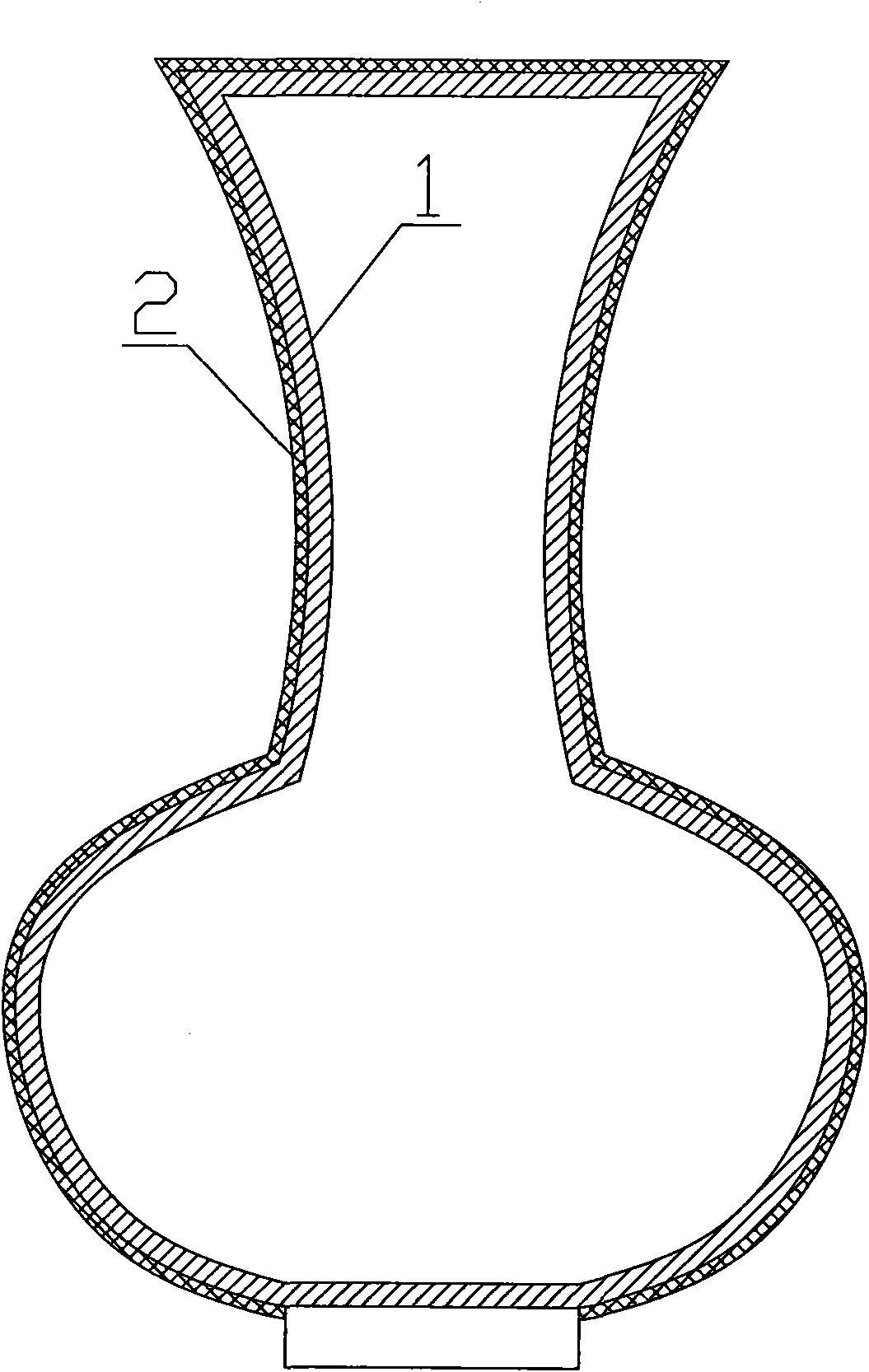

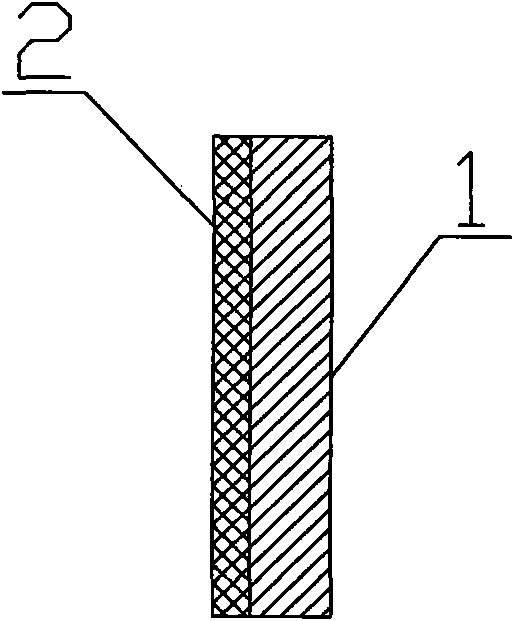

Image

Examples

Embodiment Construction

[0011] The preparation method of the present invention is carried out according to the following steps:

[0012] (1) Carry out the preparation of catalyst first, prepare pure titanium dioxide sol, adjust the pH value of sol, make the sol-type titanium dioxide photocatalyst of corresponding pH value,

[0013] (2) Carry out the coating of catalyst, make the sol-type titanium dioxide photocatalyst by 5~50mL / m 2 The amount of the photocatalytic ceramics with adjustable surface gloss is obtained by spraying, pulling, brushing or dipping on the surface of the ceramics, and then heat-treated or directly dried. The heat treatment conditions are: 100-600 ° C, time 10 to 120 minutes.

[0014] The preparation of the above catalyst is to hydrolyze titanium alkoxide (such as tetraisopropyl titanate, tetrabutyl titanate) under the condition of acidic pH<5 to obtain a uniform and transparent sol, and adjust the sol by dialysis according to the glossiness. The pH value is a certain value in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap