Early-dismantling support of aluminum alloy top plate

An aluminum alloy and formwork support technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of inconvenient use, reduced formwork construction efficiency, and complex structure of early dismantling of the support head. , to achieve the effect of improving work efficiency, conducive to civilized construction and on-site management, and easy to ensure project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

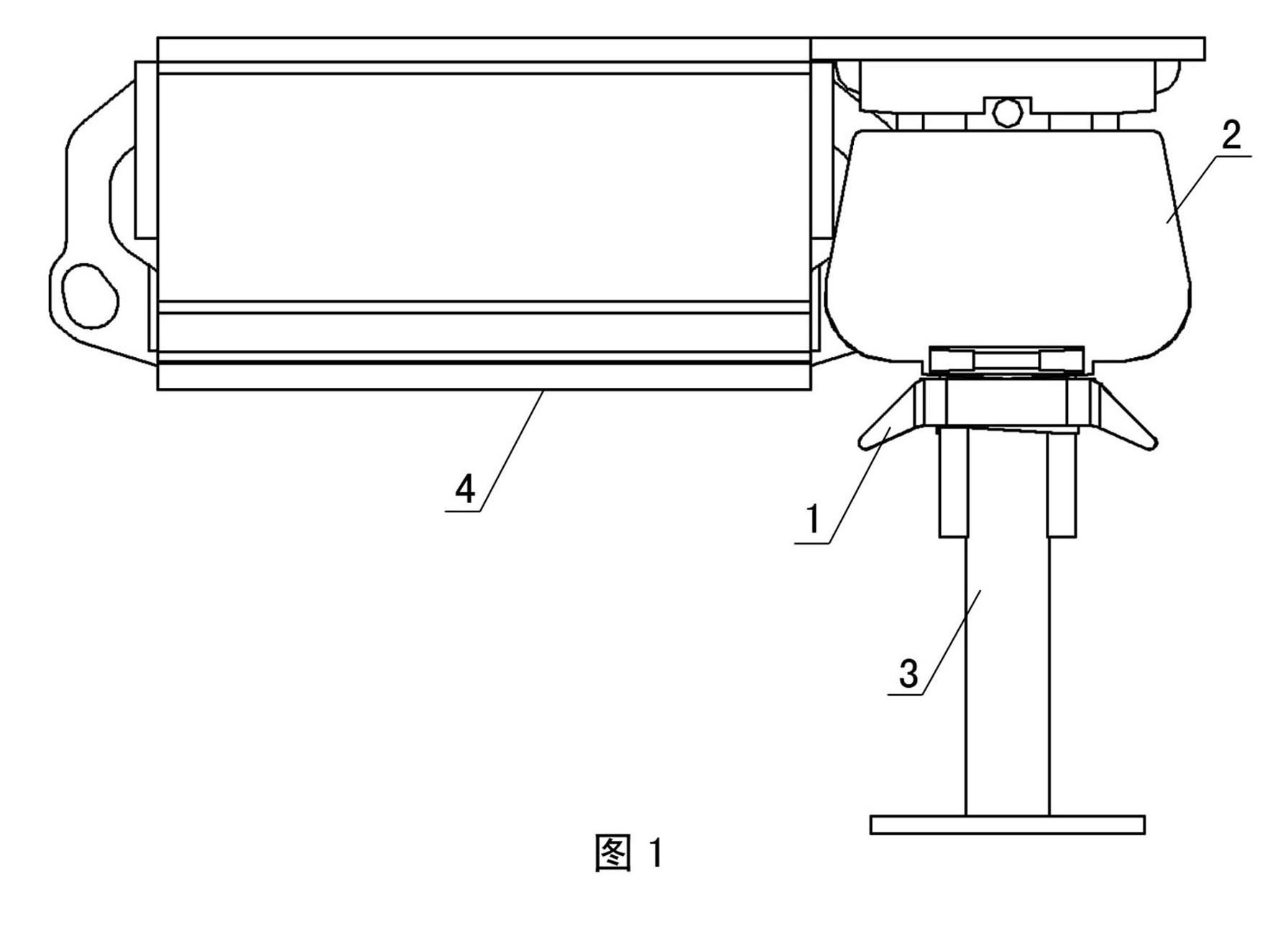

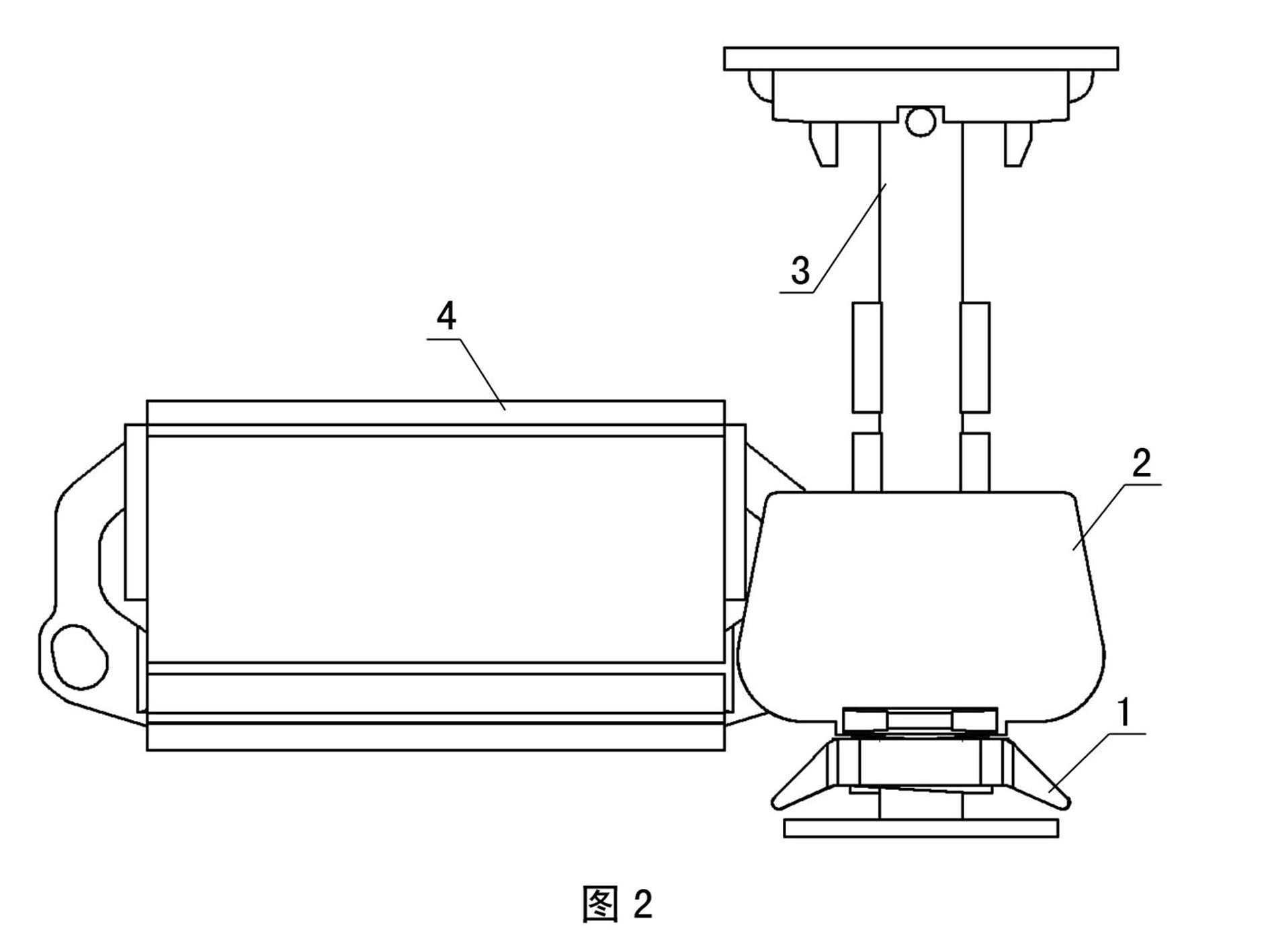

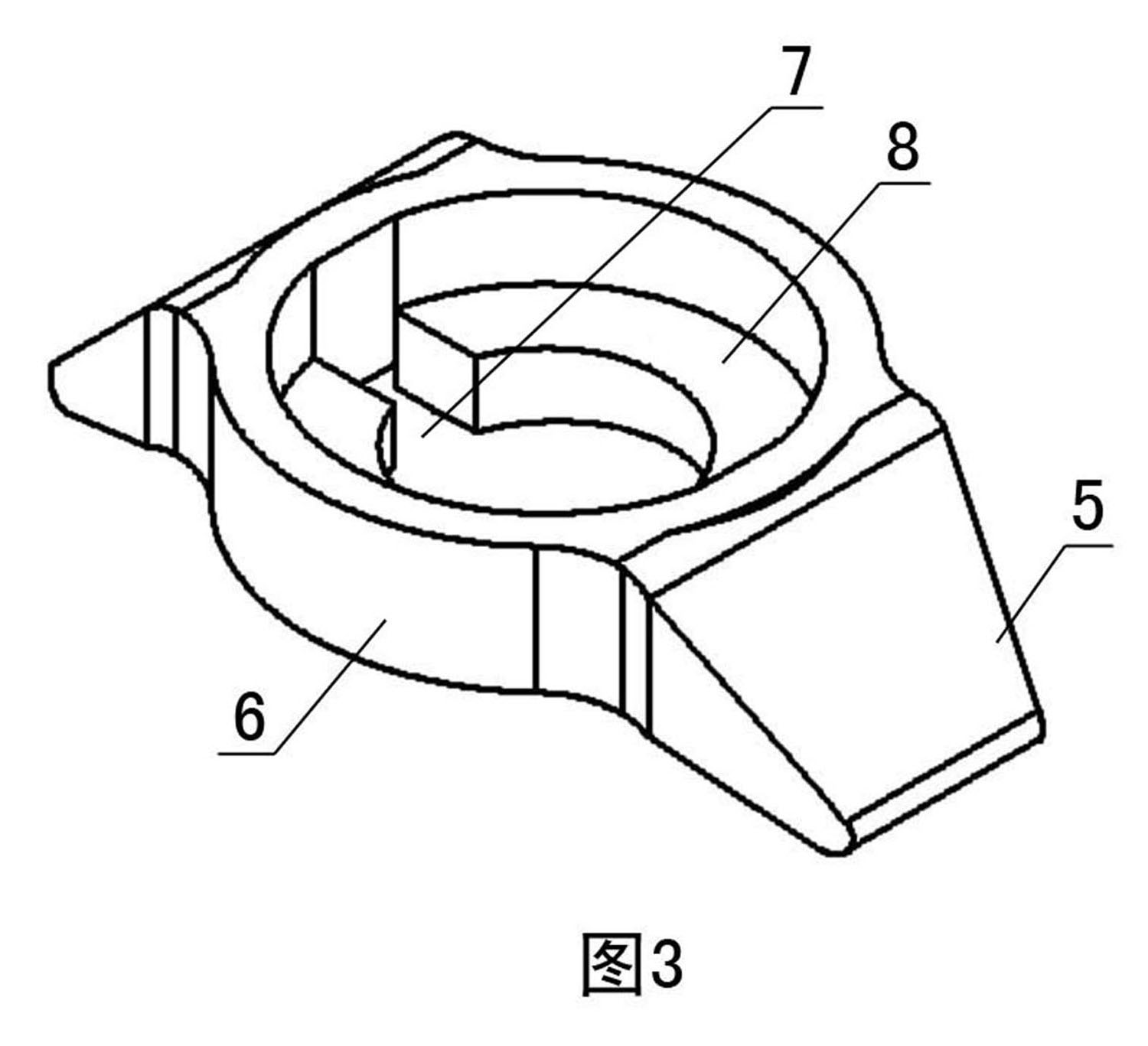

[0033] Examples see figure 1 , figure 2 As shown, the early demolition support of this aluminum alloy roof includes a support body 3 and a formwork support 4 connected to the support body, see Figure 9-11 , the supporting body 3 is composed of a vertical steel pipe 13, a lower connecting plate 14 welded at the lower end of the vertical steel pipe, an upper support plate 16 welded at the upper end of the vertical steel pipe and a stop plate 15 welded at the middle of the vertical steel pipe, wherein the lower connection There are connecting holes 17 on the plate 14, and there are at least two limiting pieces 15 that are symmetrically welded on both sides of the vertical steel pipe 13, and there are four pieces in this embodiment. Limiting pieces respectively limit the axial and rotational positions of the jacking bracket and the sliding support. The lower connecting plate is provided with connecting holes for connecting with the steel support, and the upper supporting plate is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap