Cemented carbide screw chaser material

A cemented carbide and thread comb technology, which is applied in the field of cemented carbide materials, can solve the problem that high strength and high hardness of cemented carbide cannot coexist, and achieve high strength and high hardness, high red hardness and wear resistance. Good results

Inactive Publication Date: 2014-02-19

KUNSHAN HIECISE PRECISION TOOL

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology improves how well tools made from ceramic material have their ability to resist damage during extreme temperatures without losing its effectiveness or causing issues like poor performance at these elevated temperatures. It involves combining certain metals together into specific structures called tungsten-cobalt composite particles, resulting in improved properties such as better heat conduction for cooling downsides caused by friction between them and increased durability against abrasion compared to traditional steel cutters used on metal workpieces.

Problems solved by technology

This patented technology describes how certain types of ceramic are made from tungsten powder that can be sintered together at very low temperatures without losing its effectiveness or causing damage when exposed to extreme conditions like heat generated by machining processes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

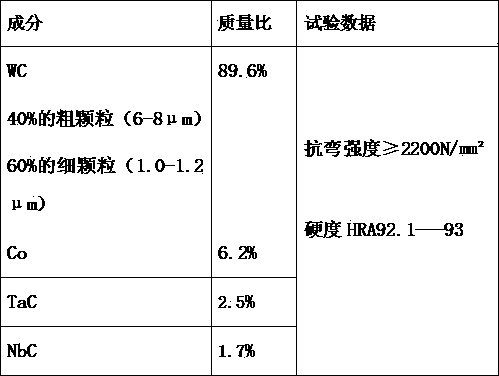

Embodiment 1

[0016]

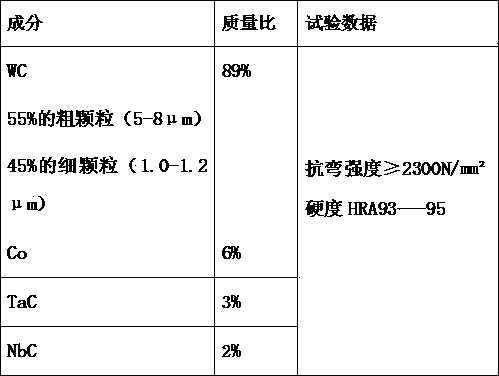

Embodiment 2

[0018]

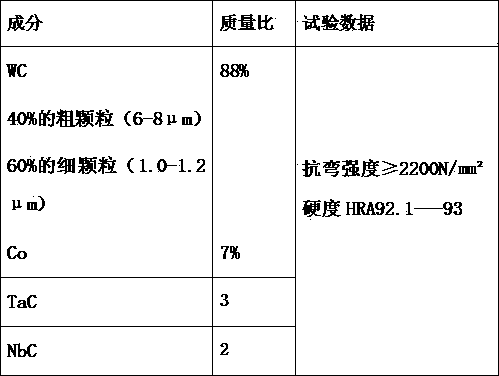

Embodiment 3

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention adopts (TaC + NbC) combined trace elements to improve the red hardness of a product, so a cutter has the advantages of high red hardness, good wear resistance, and no point folding or tipping of a cutter point under a high temperature cutting condition. The matching of a WC material belongs to a thick-thin-matched mixed crystal structure, so the high lightness and the high hardness are realized, and a problem that the high strength and the high hardness of cemented carbide cannot coexist is solved.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner KUNSHAN HIECISE PRECISION TOOL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap