Device for predicting amount of coarse flakes in coating compositions by wet color measurement

A technology for predicting devices and compositions, applied in the field of quantitative devices, can solve problems affecting the quality of coating compositions between batches, frequent interruptions of the preparation process, and tediousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

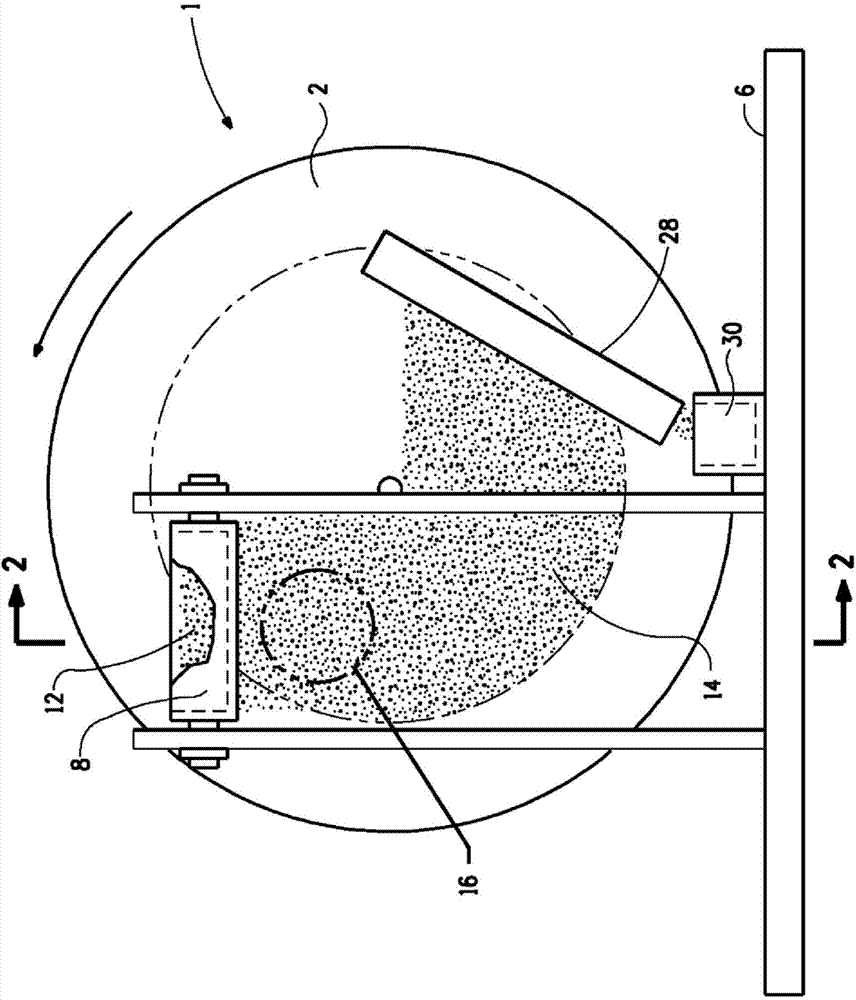

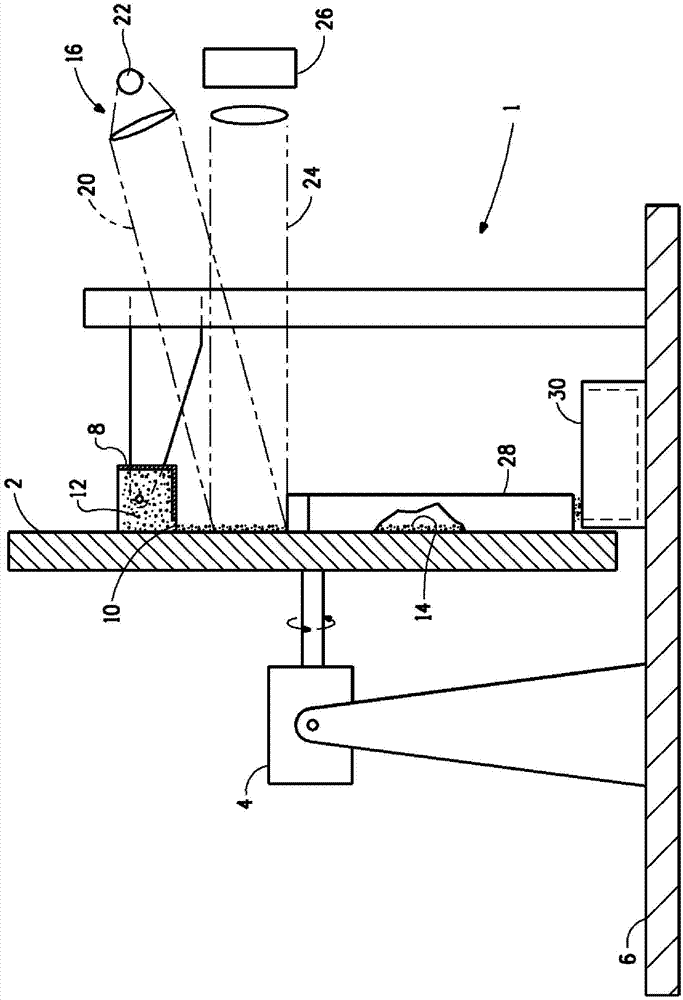

Method used

Image

Examples

Embodiment

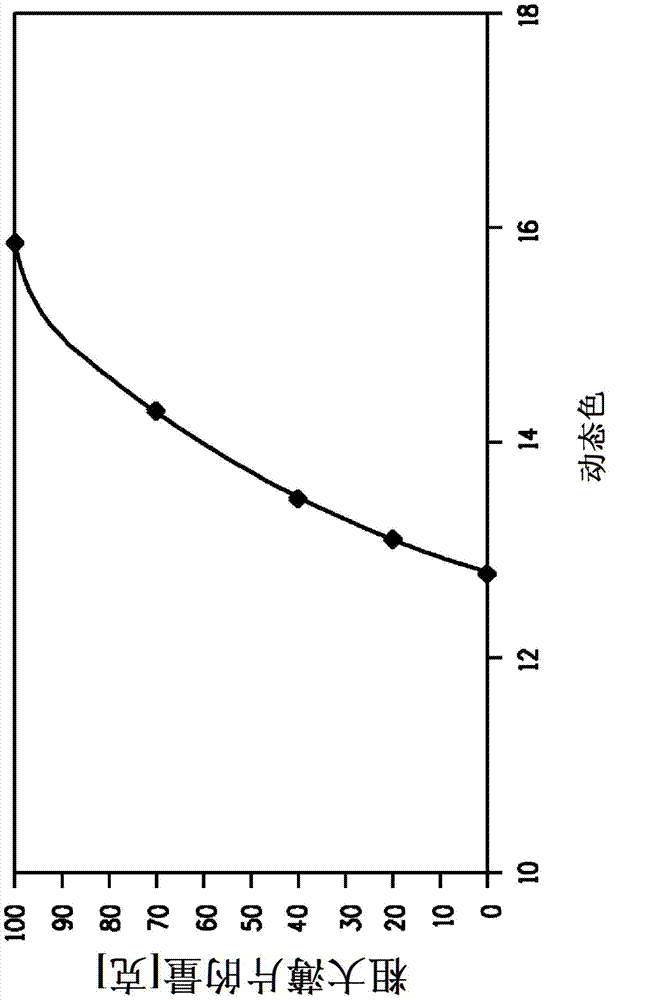

[0041] Table 1 below lists a sample of the coating composition, which includes the same as the 780 supplied by DuPont Company of Wilmington (DuPont Company of Wilmington). TM A variety of mixtures of polymer-mixed coarse flakes and fine flakes. The coarse flakes are Sparkle Silver 3641 flakes with an average size of 31 micrometers, which are produced by Silberline of Tamaqua, Pennsylvania (Pennsylvania). The thin flakes were aluminum paste 33313 flakes with an average size of 15 microns, which were supplied by Eckart of Louisville, Kentucky. The layers of these samples were applied to the substrate 2 of the device 1, and the MA-68 colorimeter 26 (MA-Rite) supplied by X-Rite of Grand Rapids, Michigan was used. 68color instrument) to measure the dynamic color of the layer:

[0042] Table 1

[0043]

Sample 1

Sample 2

Sample 3

Sample 4

Sample 5

Weight of thin flakes

100

80

60

30

0

Weight of thick slices

0

20

40

70

100

Weight of polymer

900

900

900

900

900

total weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap