Novel sand making machine

A sand making machine, a new type of technology, applied in the direction of grain processing, etc., can solve the problems of limited strength of crushed materials, slipping and wear of roller bodies and belts, and large damage to V-belts, so as to improve market competitiveness, reduce energy consumption, and maintain The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

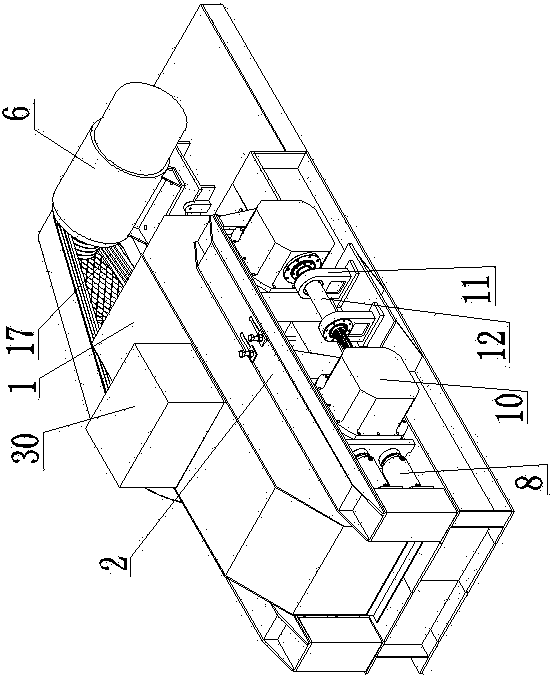

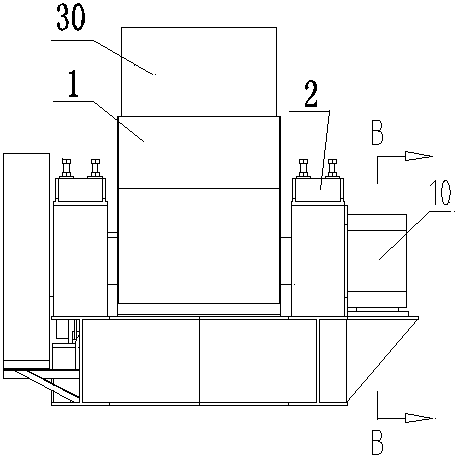

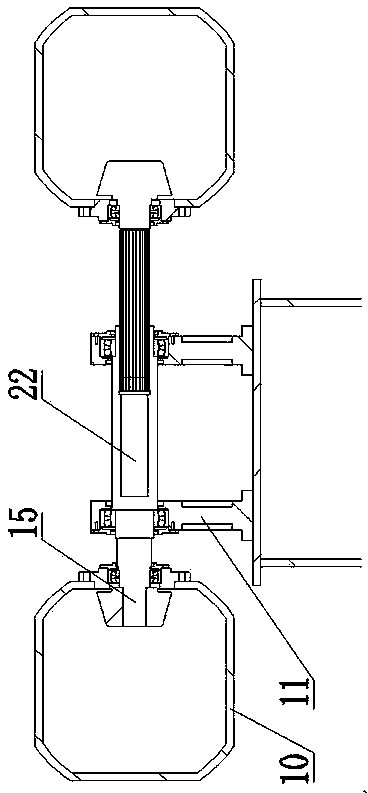

[0022] Such as figure 1 , figure 2 , Figure 4 As shown, the new sand making machine includes a frame 4, a casing 1 arranged on the frame 4, a feed port 30 is arranged above the casing 1, and a motor 6 arranged on the frame 4 through a motor base 7, The spiral bevel gear transmission 22, the fixed roller assembly 3 and the movable roller assembly 9 connected with the motor 6 through the V-belt 17 and arranged on the frame 4; and the fixed roller assembly 3 and the movable roller assembly 9 The sand-returning repairing device 21 under the two rollers, such as Figure 6 shown;

[0023] Such as Figure 4 , Figure 5 As shown, the fixed roller assembly 3 and the movable roller assembly 9 include rollers respectively arranged on the fixed shaft 19 and the movable shaft 20, and the rollers are fixed on the fixed shaft 19 and the movable shaft by rubber tires 29 and steel ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap