Oil leakage prevention motorcycle oil tank

A technology for motorcycles and oil leakage prevention, which is applied in the direction of gasoline barrels, bicycle accessories, transportation and packaging, etc. It can solve the problems of easy damage to the auxiliary fuel tank, oil leakage, and oil leakage, so as to reduce losses, reduce noise, and avoid resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

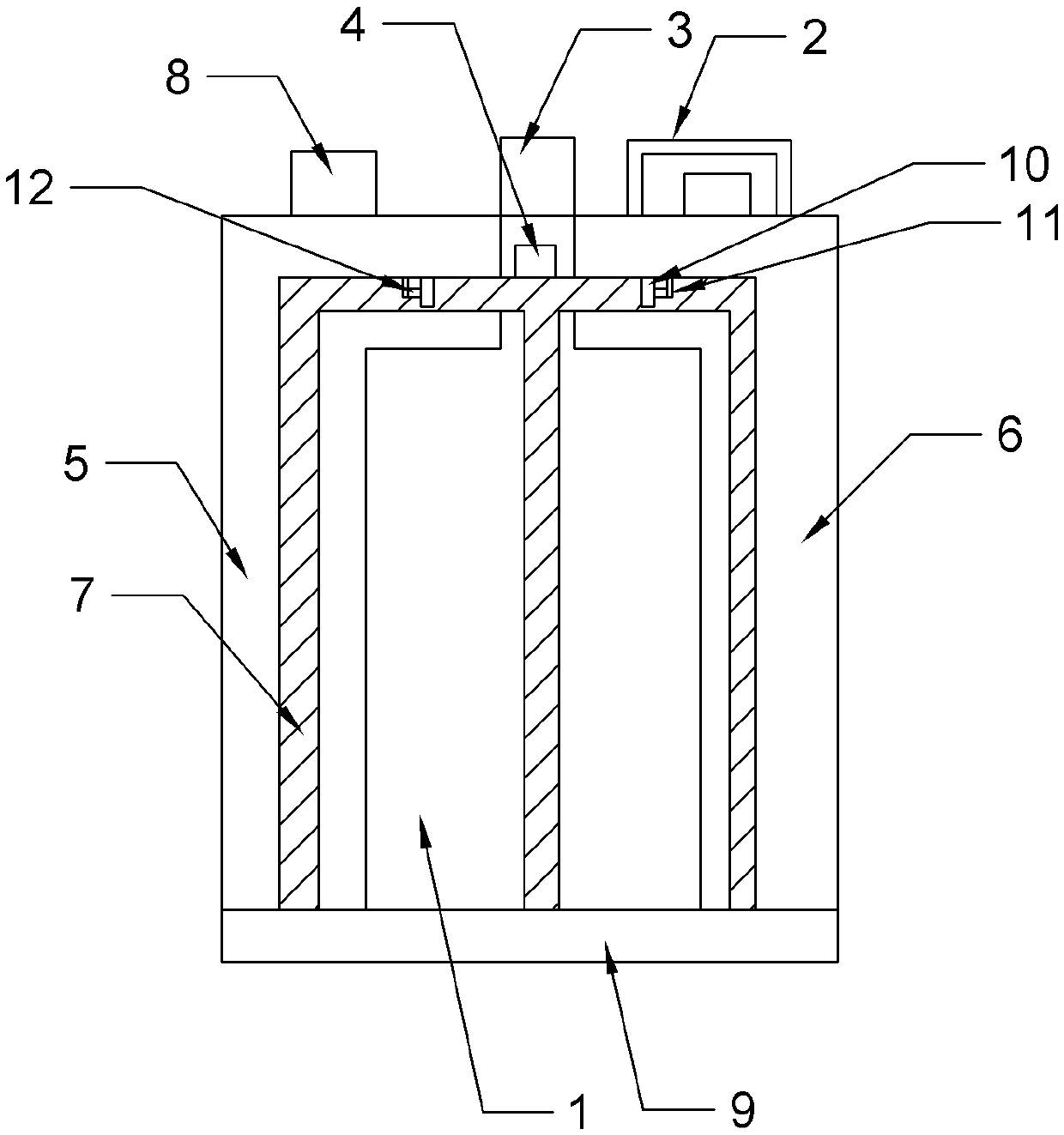

[0017] Example 1, such as figure 1 As shown, the anti-leakage motorcycle fuel tank includes a main fuel tank 1, and the upper end of the main fuel tank 1 is provided with a handle 2. A fuel filler cap 3 is provided at the opening of the main fuel tank 1, a fuel tank well 4 is provided between the main fuel tank 1 and the fuel cap 3, a first auxiliary fuel tank 5 is installed on the right side of the main fuel tank 1, and a second fuel tank is installed on the left side of the main fuel tank 1. The auxiliary fuel tank 6 also includes a three-way pipe 7. The first auxiliary fuel tank 5, the second auxiliary fuel tank 6 and the main fuel tank 1 are connected by a three-way pipe 7. The three-way port of the three-way pipe 7 is located in the wellhead 4 of the fuel tank. The upper ends of the two auxiliary oil tanks 6 are respectively provided with an oil inlet cover 8, the bottom of the main oil tank 1 is provided with a bearing frame 9, and the bottoms of the first auxiliary oil tank

Example Embodiment

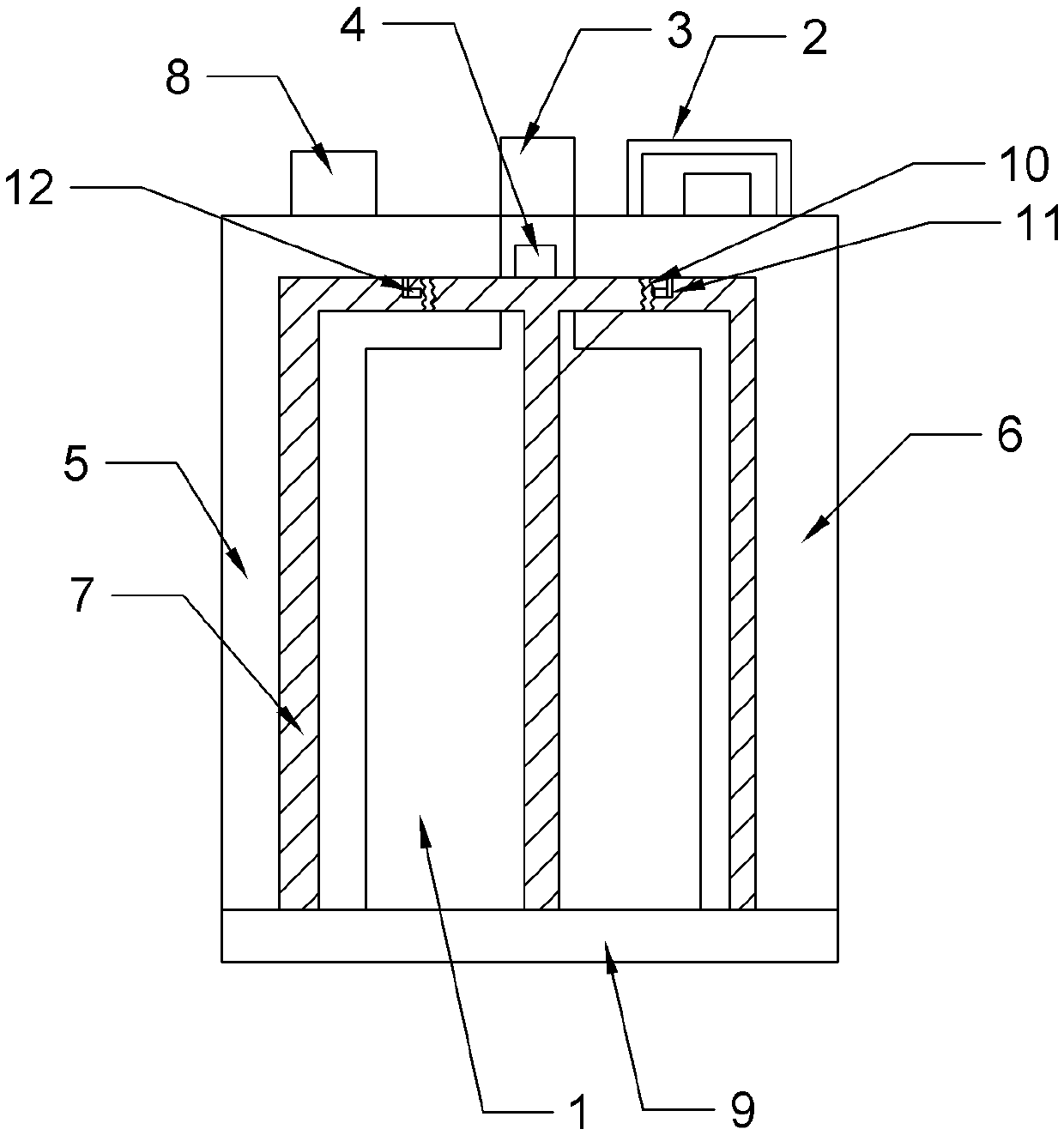

[0018] Example 2, such as figure 2 As shown, the difference from Embodiment 1 is that the cross section of the movable plate 10 is wave-shaped.

[0019] Set the oil inlets of the main oil tank 1, the first auxiliary oil tank 5 and the second auxiliary oil tank 6 respectively, and fill the main oil tank 1 first. In case of emergency, you can fill the first auxiliary oil tank 5 and the second auxiliary oil tank 6 on both sides. In this way, the three fuel tanks can be filled with oil separately without affecting each other. At the same time, the three-way pipe 7 enables the first auxiliary tank 5 and the second auxiliary tank 6 to automatically supply oil to the main tank to avoid trouble. At the same time, a movable plate 10 is set on the branch pipe of the three-way pipe 7, and the baffle 12 is used to block it below, so that the oil in the main tank 1 cannot leak into the first auxiliary tank 5 and the second auxiliary tank 6, but the first auxiliary tank The oil in 5 and the se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap