Pre-tensioning-method prestressed centrifugally-formed precast high-strength concrete hollow I-shaped support pile

A high-strength concrete, centrifugal forming technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high engineering cost, poor quality and safety controllability, waste of resources, etc. Good social benefits and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

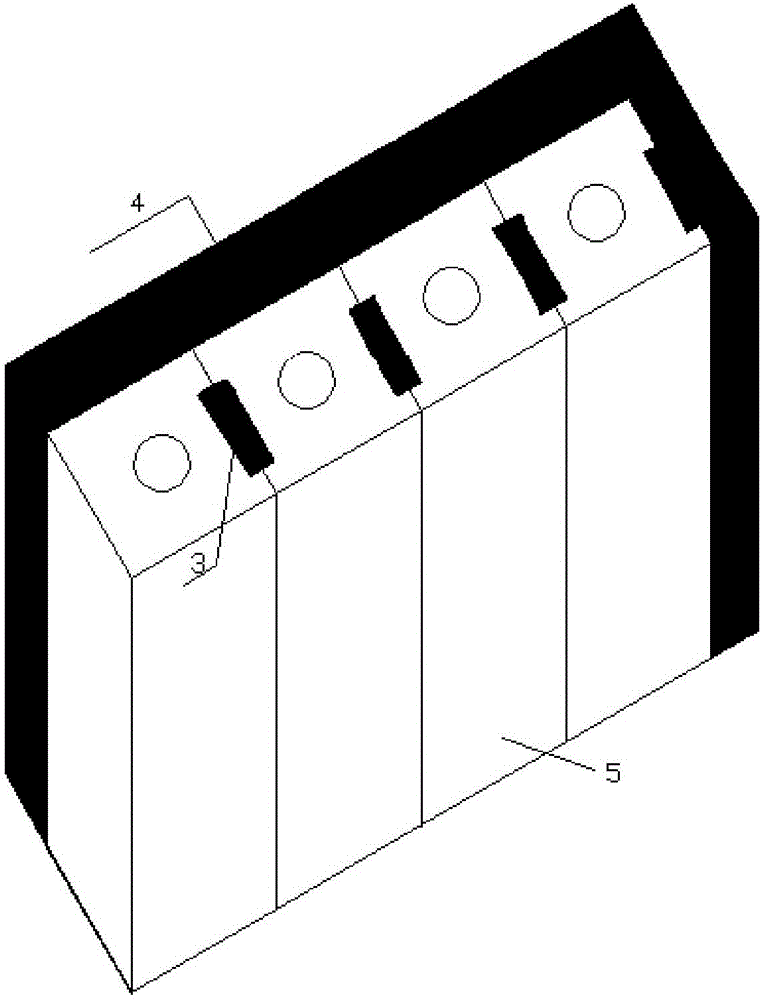

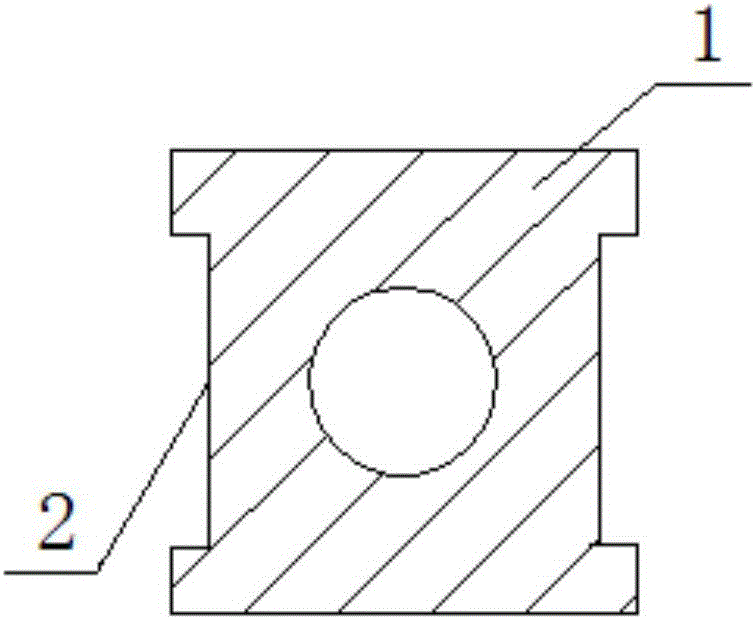

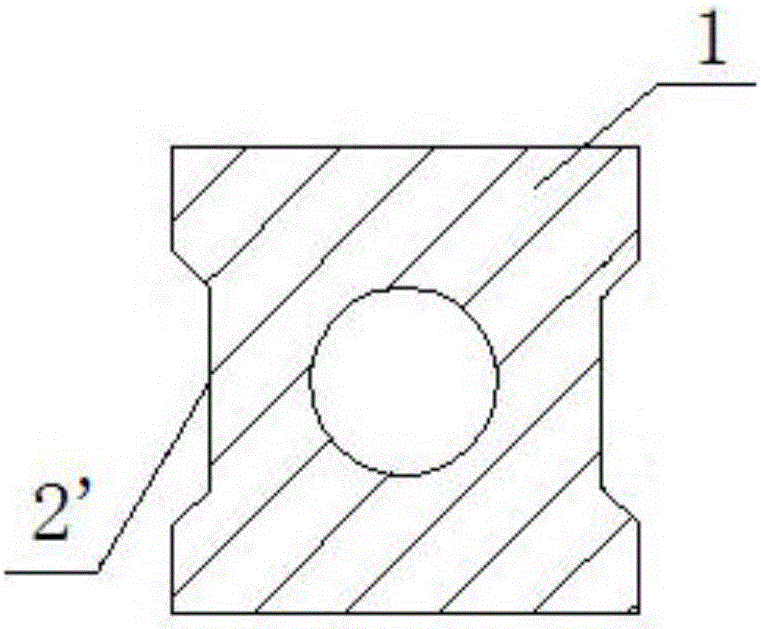

[0018] With reference to the accompanying drawings, a pre-tensioned pre-stressed centrifugal forming high-strength concrete prefabricated hollow I-shaped supporting pile of the present invention will be described.

[0019] The tensioning prestressed centrifugal forming high-strength concrete prefabricated hollow I-shaped supporting piles of the present invention are composed of several piles 1 arranged in close proximity and implanted in the lower section or pressed into the ground. The structure of the pile 1 is: longitudinally from the end to the end Water-stop grooves are arranged symmetrically; the number of water-stop grooves on each side is one (the shape of the water-stop groove is rectangular 2 and trapezoidal 2'); the water-stop holes of two adjacent piles 1 are combined into one (water-stop The hole shape is rectangular 3 and ladder 3'). The column is filled with cement slurry 4; after the cement slurry is hardened and solidified, the precast concrete piles are cemented and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap