Method for preparing calcium sulfate from ardealite

A technology of phosphogypsum and calcium sulfate, applied in the field of solid waste resource utilization, can solve the problem that phosphogypsum cannot be effectively recycled and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

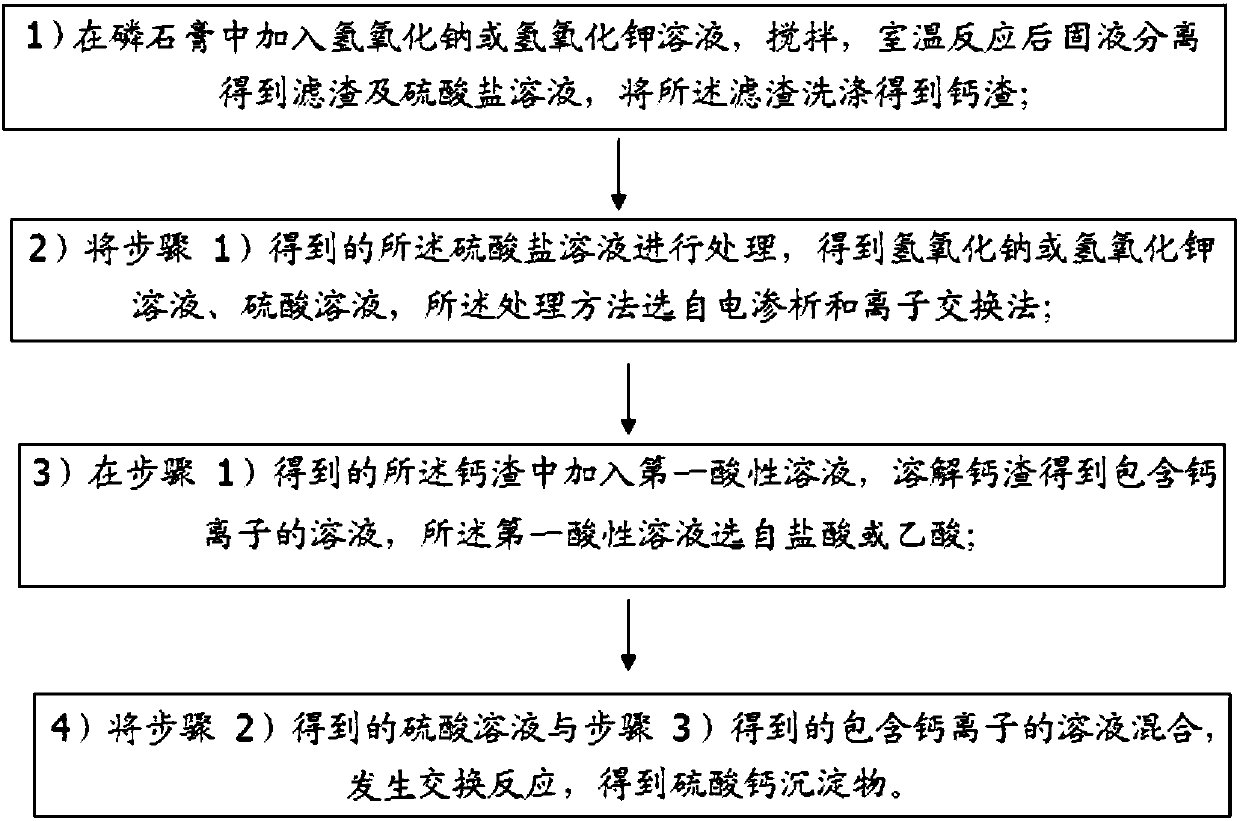

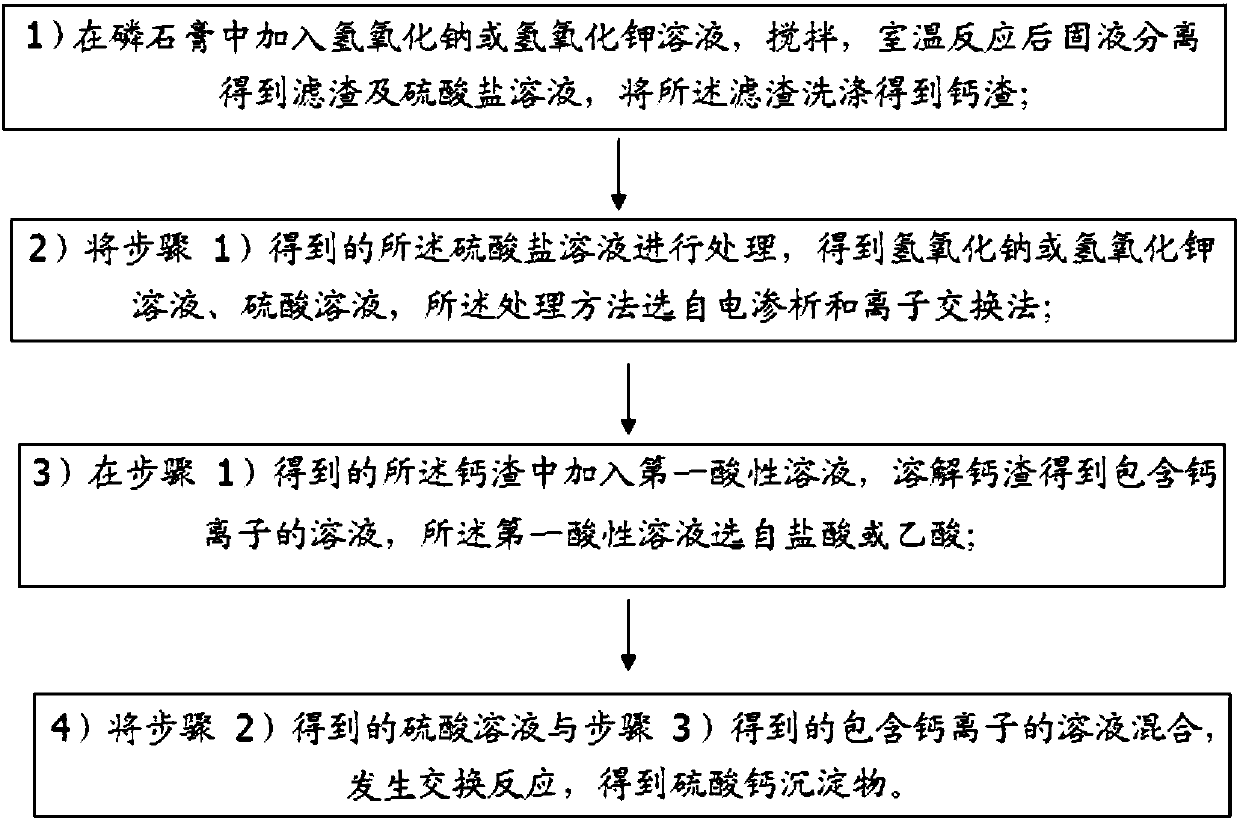

Method used

Image

Examples

Embodiment 1

[0038] The raw material of this embodiment is phosphogypsum provided by Hubei Xingfa Chemical Group Co., Ltd. Its main components are: CaO 28.98%, P 2 o 5 1.09%, SiO 2 6.06%, MgO 0.18%, Al 2 o 3 0.42%, SO 3 42.32%, CaSO 4 70.36%, crystal water 16.01%. X-ray diffraction analysis shows that the main component of phosphogypsum is CaSO 4 , followed by SiO 2 , and a small amount of colloidal phosphate and aluminosilicate.

[0039] The present embodiment prepares the circulation process of high-purity calcium sulfate by phosphogypsum, is characterized in that comprising the steps:

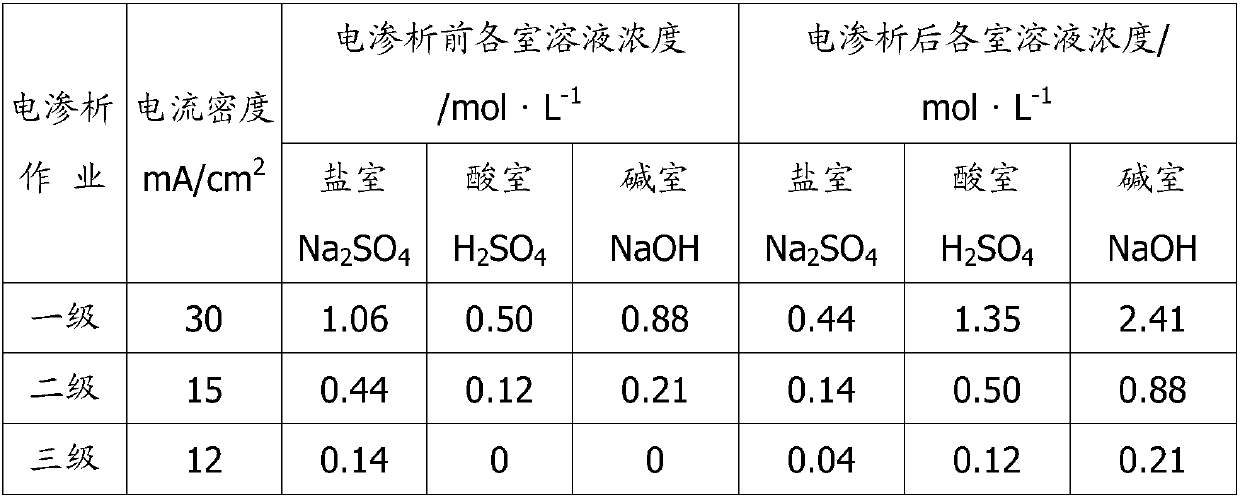

[0040] (1) Decompose phosphogypsum with NaOH solution: slowly add NaOH solution with a concentration of 2.40mol / L to the reactor containing phosphogypsum raw materials according to the dosage of 11.4mol NaOH / 1kg phosphogypsum, and stir while adding , reacted at room temperature for 10 min. Then the slurry is filtered, and the filter residue is countercurrently washed twice to obtain Na wit

Embodiment 2

[0053] The raw material of this embodiment is phosphogypsum provided by Hubei Xingfa Chemical Group Co., Ltd. Its main components are: CaO 28.98%, P 2 o 5 1.09%, SiO 2 6.06%, MgO 0.18%, Al 2 o 3 0.42%, SO 3 42.32%, CaSO 4 70.36%, crystal water 16.01%. X-ray diffraction analysis shows that the main component of phosphogypsum is CaSO 4 , followed by SiO 2 , and a small amount of colloidal phosphate and aluminosilicate.

[0054] The present embodiment prepares the circulation process of high-purity calcium sulfate by phosphogypsum, is characterized in that comprising the steps:

[0055] (1) Decompose phosphogypsum with KOH solution: slowly add KOH solution with a concentration of 1.80mol / L to the reactor containing phosphogypsum raw material according to the amount of 10mol NaOH / 1kg phosphogypsum, and stir while adding, React at room temperature for 20 min. Then the slurry is filtered, and the filter residue is countercurrently washed twice to obtain a K concentrat

Embodiment 3

[0066] The raw material of this embodiment is phosphogypsum provided by Hubei Xingfa Chemical Group Co., Ltd. Its main components are: CaO 28.98%, P 2 o 5 1.09%, SiO 2 6.06%, MgO 0.18%, Al 2 o 3 0.42%, SO 3 42.32%, CaSO 4 70.36%, crystal water 16.01%. X-ray diffraction analysis shows that the main component of phosphogypsum is CaSO 4 , followed by SiO 2 , and a small amount of colloidal phosphate and aluminosilicate.

[0067] The present embodiment prepares the circulation process of high-purity calcium sulfate by phosphogypsum, is characterized in that comprising the steps:

[0068] (1) Decompose phosphogypsum with KOH solution: slowly add the NaOH solution with a concentration of 2.60mol / L to the reactor containing the phosphogypsum raw material according to the amount of 12mol KOH / 1kg phosphogypsum, and stir while adding, React at room temperature for 8 minutes. Then the slurry is filtered, and the filter residue is countercurrently washed twice to obtain a K

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap