Carbon fiber composite plate and manufacturing method thereof

A technology of carbon fiber board and production method, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, building materials, etc., can solve the problems of easy expansion and delamination of carbon fiber board, and achieve the purpose of improving static bending strength, improving anhydrous, Avoid the effect of board expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

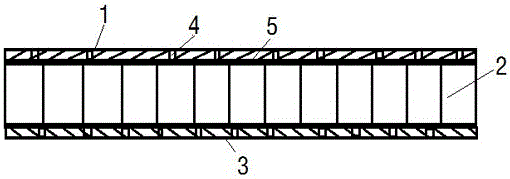

[0020] As shown in Figure 1, the present invention provides a carbon fiber composite board, including a protective layer; the protective layer includes a first protective layer 1 plate and a second protective layer 2; the first protective layer 1 and the second protective layer plate There is a board core inlaid between 2 and the board core is a carbon fiber board core 2. The first protective layer 1 and the second protective layer 2 are provided with through holes 4; the through holes 4 respectively pass through the first protective layer and the second protective layer. The sheath plate is connected with the plate core; the arrangement of the through hole 4 is mainly to improve the removal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap