Carbon fiber composite material for main rotor of helicopter and preparation method of composite material

A composite material and main rotor technology, applied in the direction of rotorcraft, motor vehicles, coatings, etc., can solve the problems of poor coating effect, inconvenient cleaning of the coating chamber, and low efficiency of carbon fiber plate coating, so as to improve Effect of improving tensile strength and friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A carbon fiber composite material for a helicopter main rotor, prepared from the following raw materials in parts by weight: 30 parts of graphene modified phenolic resin, 3 parts of carbon fiber board, 4 parts of hexamethylenetetramine, 10 parts of wollastonite, 2 parts carbon black, 1 part calcium hydroxide;

[0033] Among them, the preparation process of the carbon fiber composite material for the main rotor of the helicopter is as follows:

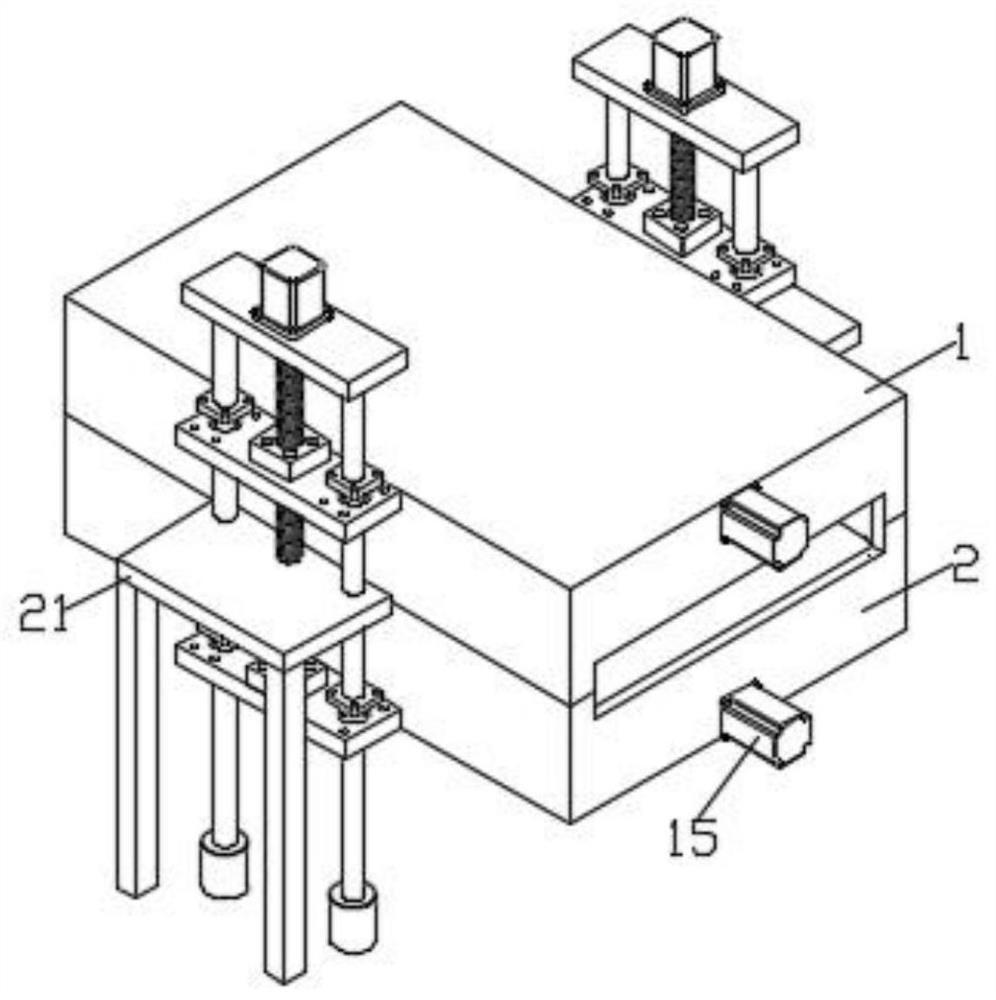

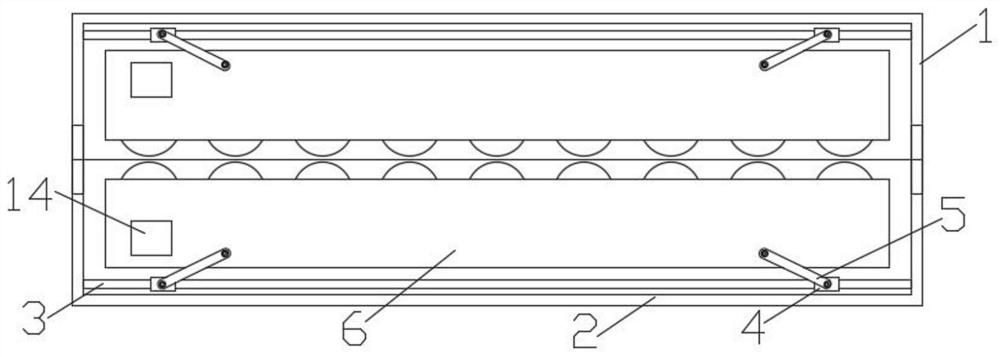

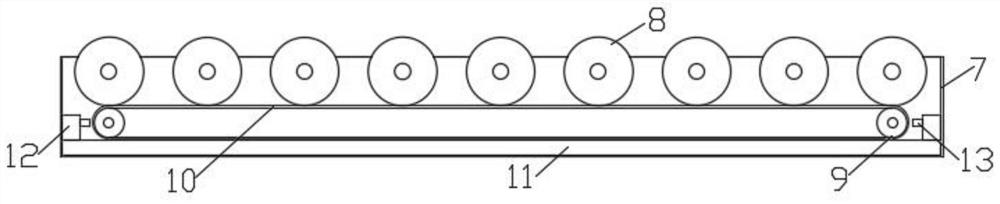

[0034] Step 1: Put the carbon fiber plate into the openings on the side of the upper coating chamber 1 and the lower coating chamber 2, turn on the adjustment motor 15, the output shaft of the adjustment motor 15 drives the first lead screw 3 to rotate, and the first lead screw 3 drives the two The two adjusting blocks 4 move towards each other, the adjusting block 4 drives the two rotating rods 5 to rotate, the four rotating rods 5 drive the lifting shell 7 to move, and then the two lifting shells 7 move towards each other, the con

Embodiment 2

[0044] A carbon fiber composite material for a helicopter main rotor, prepared from the following raw materials in parts by weight: 35 parts of graphene modified phenolic resin, 5 parts of carbon fiber board, 6 parts of hexamethylenetetramine, 15 parts of wollastonite, 4 parts Carbon black, 2 parts calcium hydroxide;

[0045] Among them, the preparation process of the carbon fiber composite material for the main rotor of the helicopter is as follows:

[0046] Step 1 is the same as in Example 1.

[0047] Step 2: Weigh phenol, formaldehyde, and zinc oxide according to the mass ratio of 55:55:1.2, and then sequentially add them into a four-neck bottle containing condensed water, heat up the reaction, and dehydrate under vacuum until the water content is less than 4%. Adjust the viscosity with methanol and cool it below 38°C to obtain phenolic resin;

[0048] Step 3: Disperse graphene in phenolic resin according to the mass ratio of 2:3, then add it into a four-necked flask contain

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap