A ball mill hydraulic control system based on amesim

A hydraulic control system and ball mill technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve problems such as large motor mass, circuit tripping, and long operating intervals, and reduce maintenance costs and risks. good effect of anti-pollution and anti-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

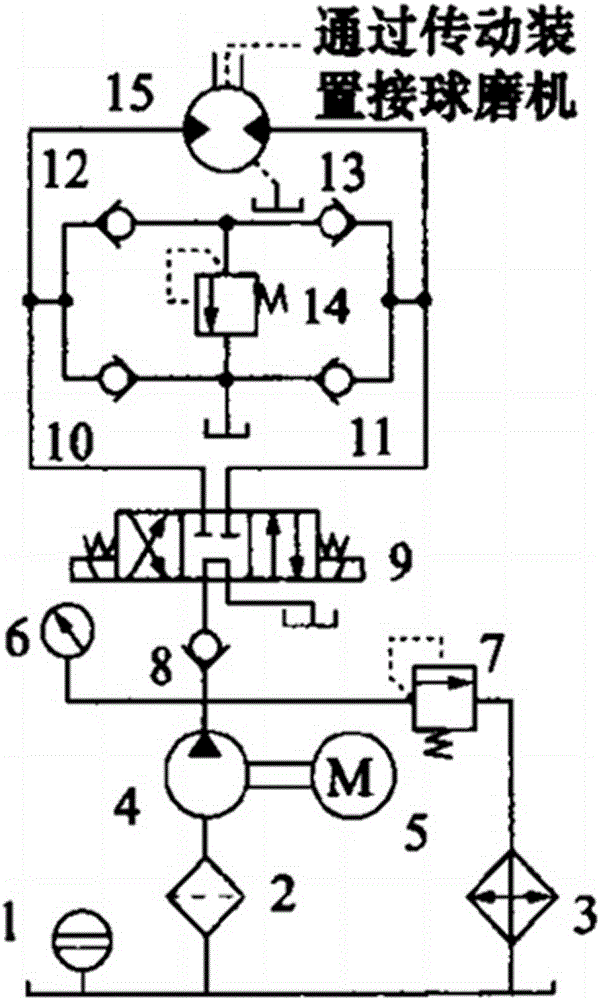

[0012] like figure 1 , the system selects the common one-way hydraulic pump model 4 as the power component of the system, and controls the steering of the ball mill by using the three-position four-way electromagnetic reversing valve 9 . At the same time, considering the large mass of the ball mill itself, a low-speed high-torque hydraulic motor is used as the actuator, and if the speed of the hydraulic motor is appropriate, the deceleration device may not be used. In actual operation, the distance between the hydraulic motor and the hydraulic oil station can be increased to remotely control the ball mill.

[0013] Due to the large inertia of the low-speed high-torque hydraulic motor when braking, the control system uses the overflow bridge circuit to control the hydraulic motor. When the three-position four-way electromagnetic reversing valve 9 returns to the neutral po

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap