Ball grinding machine for improving discharging quality and with classification function

A ball mill and quality technology, which is applied in the direction of filtration separation, separation method, grain processing, etc., can solve the problems of affecting product quality, not undergoing very strict grading treatment, reducing the utilization rate of raw materials and added value, and achieving the improvement of product added value. Value, simple structure, good promotion and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

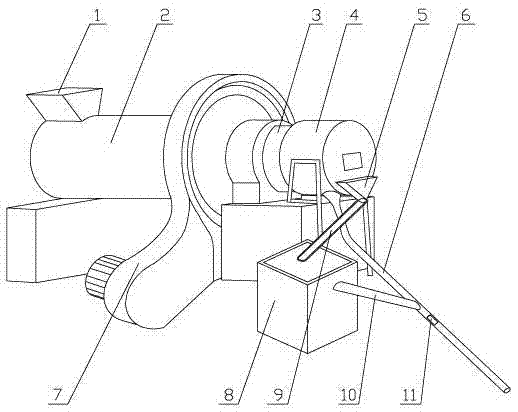

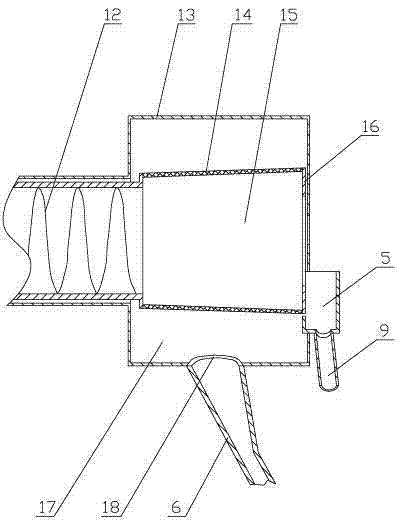

[0013] see figure 1 , figure 2 , the present invention is a ball mill with a classification function for improving the discharge quality. It has a ball mill cylinder 2, the cylinder is provided with a feed port 1, and the front of the cylinder is provided with a transmission device 7 and a discharge device 3. The discharge device A spiral material guide device 12 is provided inside, and a discharge grading device 4 is provided at the front of the discharge device, and the discharge grading device includes a cylindrical cover 13 fixedly connected with the cylinder laterally, the cylindrical cover There is a truncated conical screen 14 in the horizontal direction, the screen is fixedly connected to the screw guide device and rotates with it, the two ends of the screen are open, and the end with a small opening diameter of the screen is fixed to the screw guide device. Connection, the end of the screen with a large opening diameter is provided with a ring-shaped baffle 16, and a c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap