Composite filter plant for fresh air fan

A technology of composite filtration and fresh air blower, applied in the field of filtration devices, can solve the problems of inability to perform water washing, increase cost, increase operation complexity, etc., and achieve the effect of high storage charge density and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

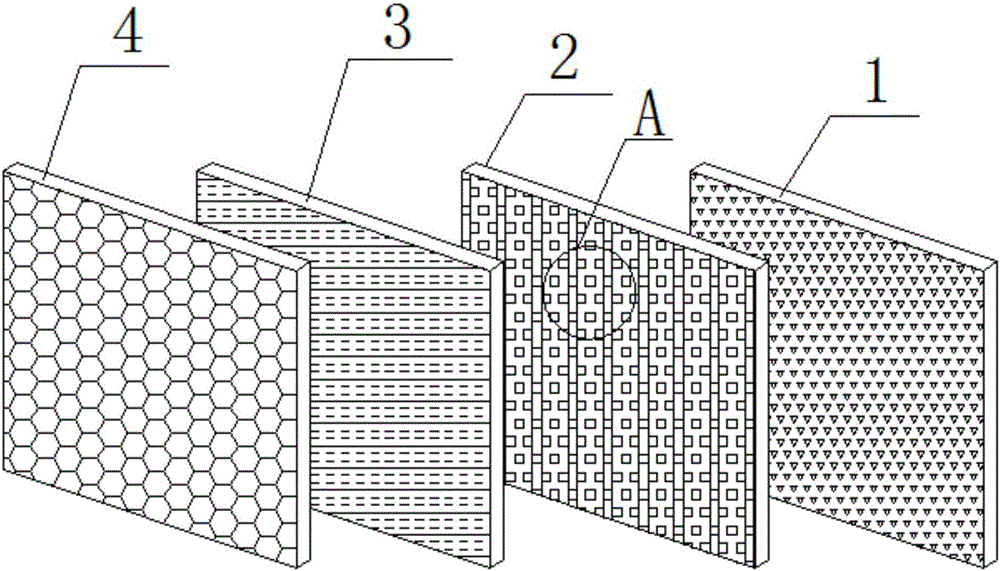

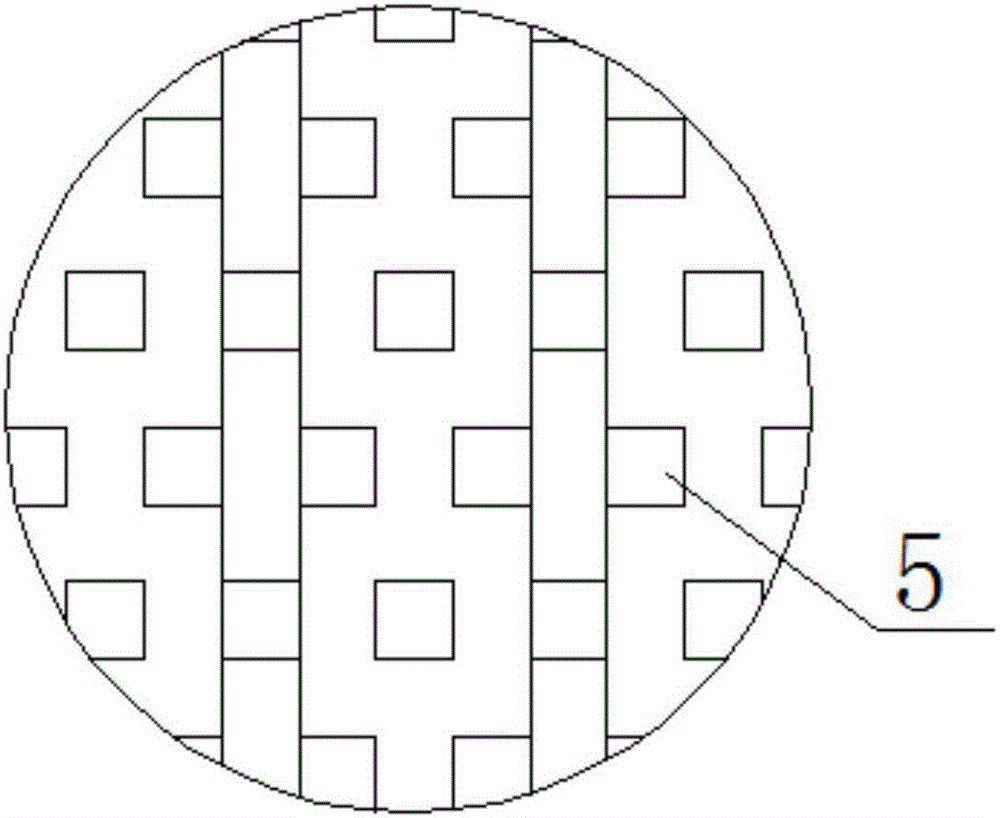

[0020] Such as Figure 1 to Figure 2 As shown, the present invention includes primary effect filter screen 1, high-efficiency air filter screen 4, electrostatic dust removal filter screen 2 and photocatalyst filter screen 3, and electrostatic dust removal filter screen 2 and photocatalyst filter screen 3 are arranged on primary effect filter screen 1 and high-efficiency air filter screen Between the nets 4, the photocatalyst filter screen 3 is made of a film filter screen mixed with nano-scale titanium dioxide and tolyltriazole and the surface is coated with a transition metal complex; the material of the electrostatic dust filter screen 2 is adopted Polypropylene after electrostatic electret treatment.

[0021] Further, the transition metal complex is a ruthenium complex or a porphyrin platinum or palladium complex.

[0022] Further, the electrostatic electret method is corona discharge.

[0023] Further, the tol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap