Dragon fruit pulp and concentration time shortening preparation method thereof

A technology for pitaya and fruit pulp is applied in the field of preparation of pitaya pulp and shortening of concentration time, can solve problems such as loss, unsatisfactory storage effect, short storage and fresh-keeping period of pitaya, and achieves the effect of increasing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

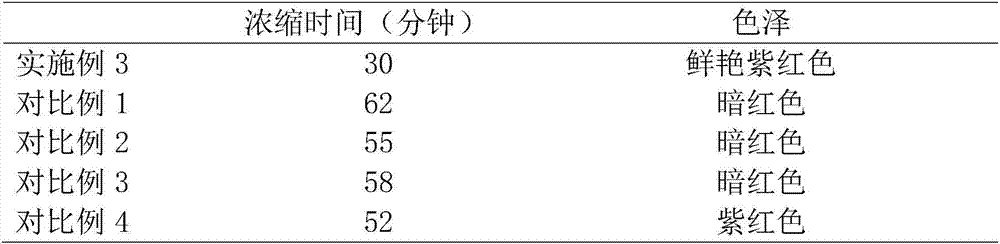

Examples

Embodiment 1

[0029] A preparation method for shortening the concentration time of dragon fruit pulp, comprising the steps of:

[0030]1) Pre-treatment: sort fresh dragon fruits, remove rotten fruits and small immature fruits, cut off moth-eaten parts and dry scabs before cleaning, dig more rotten parts, pour the selected dragon fruits into the conveyor Belt, transported to the bubble washing machine, pay attention to the short cleaning time, and wash as you put it;

[0031] 2) Beating: Send the cleaned fruit into a beater with a sieve plate aperture of 0.7-1.0 mm for beating;

[0032] 3) Heating and degumming: Add the pulp prepared in step 2) into pure water of equal weight, heat it to 100°C in a stainless steel jacketed pot, keep it for 5 minutes, filter out the floating foam, and filter the sediment with a 100-mesh filter cloth;

[0033] 4) Ingredients and concentration: Mix white sugar and xanthan gum evenly in a weight ratio of 48:2 to obtain a mixture, then add it to the material obtain

Embodiment 2

[0036] A preparation method for shortening the concentration time of dragon fruit pulp, comprising the steps of:

[0037] 1) Pre-treatment: sort fresh dragon fruits, remove rotten fruits and small immature fruits, cut off moth-eaten parts and dry scabs before cleaning, dig more rotten parts, pour the selected dragon fruits into the conveyor Belt, transported to the bubble washing machine, pay attention to the short cleaning time, and wash as you put it;

[0038] 2) Beating: Send the cleaned fruit into a beater with a sieve plate aperture of 0.7-1.0 mm for beating;

[0039] 3) Heating and degumming: Add the pulp prepared in step 2) into pure water of equal weight, heat it to 100°C in a stainless steel jacketed pot, keep it for 5 minutes, filter out the floating foam, and filter the sediment with a 100-mesh filter cloth;

[0040] 4) Ingredients and concentration: Mix white sugar and xanthan gum evenly in a weight ratio of 48:2 to obtain a mixture, then add it to the material obtai

Embodiment 3

[0043] A preparation method for shortening the concentration time of dragon fruit pulp, comprising the steps of:

[0044] 1) Pre-treatment: sort fresh red dragon fruit, remove rotten fruit and immature small fruit, cut off moth-eaten parts and dry scabs before cleaning, dig more rotten parts, pour the selected dragon fruit into Conveyor belt, transported to the bubble washing machine, pay attention to the short cleaning time, and wash as you put it;

[0045] 2) Beating: Send the cleaned fruit into a beater with a sieve plate aperture of 0.7-1.0 mm for beating;

[0046] 3) Heating and degumming: Add the pulp prepared in step 2) into pure water of equal weight, heat it to 100°C in a stainless steel jacketed pot, keep it for 5 minutes, filter out the floating foam, and filter the sediment with a 100-mesh filter cloth;

[0047] 4) Ingredients and concentration: Mix white sugar and xanthan gum evenly in a weight ratio of 48:2 to obtain a mixture, then add it to the material obtained

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap