Waterborne quick-drying anticorrosive primer for high-speed rail train body

An anti-corrosion paint, water-based technology, applied in anti-corrosion coatings, coatings, chitin polysaccharide coatings and other directions, can solve the problems of water-based anti-corrosion paint fast drying and mechanical properties can not meet the needs of specific occasions, to achieve low VOC emissions, improve Overall performance, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

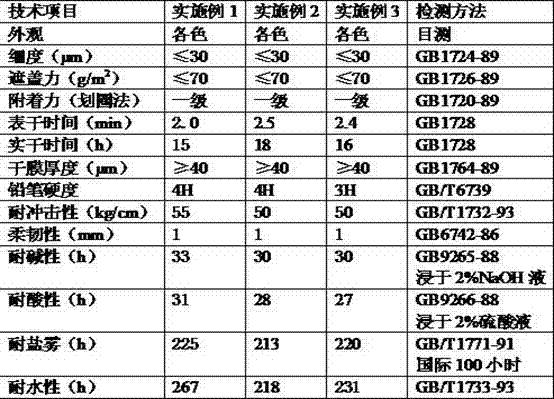

Examples

Embodiment 1

[0020] Raw material composition: 10 parts of water-based methacrylic epoxy resin, 10 parts of water-based acrylic resin, 4 parts of chitosan, 11 parts of antirust pigment, 18 parts of talcum powder, 0.1 part of cationic FM emulsifier, polycarboxylate sodium salt dispersant 0.1 part, 1 part of sodium nitrite, 0.1 part of water-based acrylic drier, 0.3 part of pH regulator, and 35 parts of deionized water.

[0021] Preparation method steps: antirust pigment, talcum powder, 1 / 2 cationic FM emulsifier, 1 / 2 polycarboxylate sodium salt dispersant, sodium nitrite, 1 / 2 water-based acrylic drier and pH regulator Stir evenly after mixing; disperse the mixed slurry at high speed, and then grind until the fineness of the slurry is ≤30μm; then add water-based methacrylic epoxy resin, water-based acrylic resin, and the remaining cationic FM emulsification to the slurry agent, the remaining polycarboxylate sodium salt dispersant, the remaining water-based acrylic acid drier and water, sti

Embodiment 2

[0023] Raw material composition: 8 parts of water-based methacrylic epoxy resin, 9 parts of water-based acrylic resin, 4 parts of chitosan, 9 parts of anti-rust pigment, 17 parts of talcum powder, 0.2 parts of cationic FM emulsifier, polycarboxylate sodium salt dispersant 0.1 part, 1 part of sodium nitrite, 0.1 part of water-based acrylic drier, 0.2 part of pH regulator, 33 parts of deionized water.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Raw material composition: 10 parts of water-based methacrylic epoxy resin, 9 parts of water-based acrylic resin, 4 parts of chitosan, 13 parts of antirust pigment, 18 parts of talcum powder, 0.1 part of cationic FM emulsifier, polycarboxylate sodium salt dispersant 0.1 parts, 2 parts of sodium nitrite, 0.2 parts of water-based acrylic acid drier, 0.2 parts of pH regulator, 40 parts of deionized water.

[0027] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap