Submicron lithium manganite for positive electrode of lithium ion battery and preparation method of submicron lithium manganite

A lithium-ion battery, grade lithium manganate technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of short electron and ion transport channels, unsuitable for commercial applications, capacity decay, etc. The effect of good performance, low cost and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

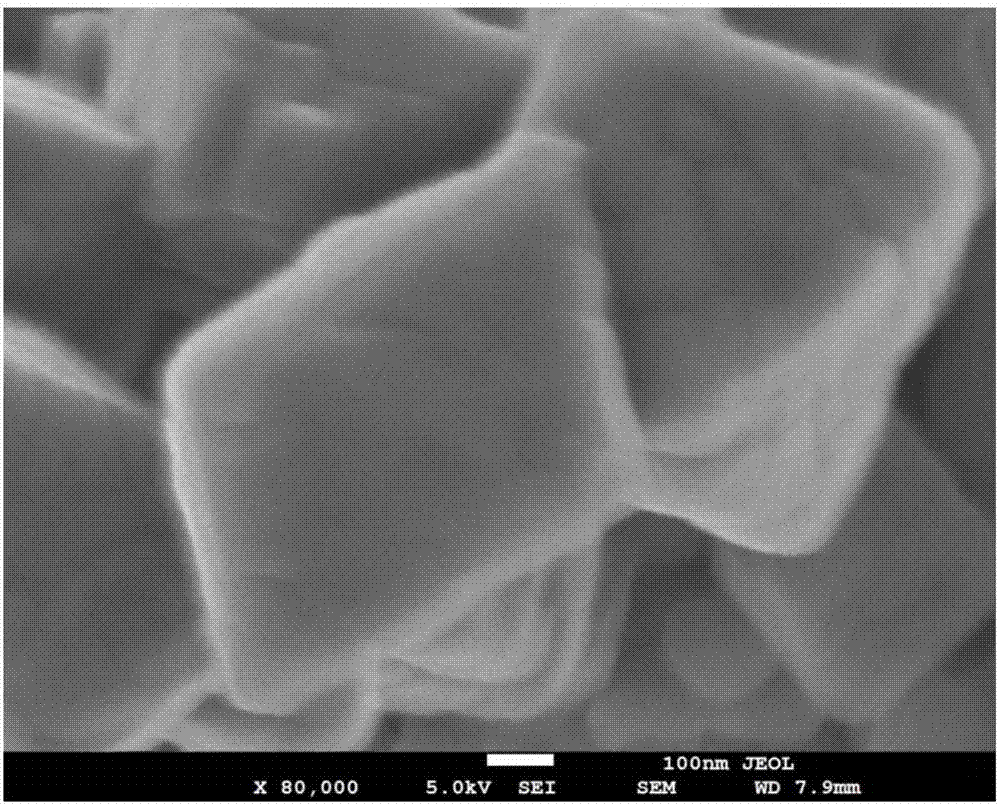

[0034] A preparation method of submicron lithium manganese oxide for positive electrode of lithium ion battery, comprising the steps of:

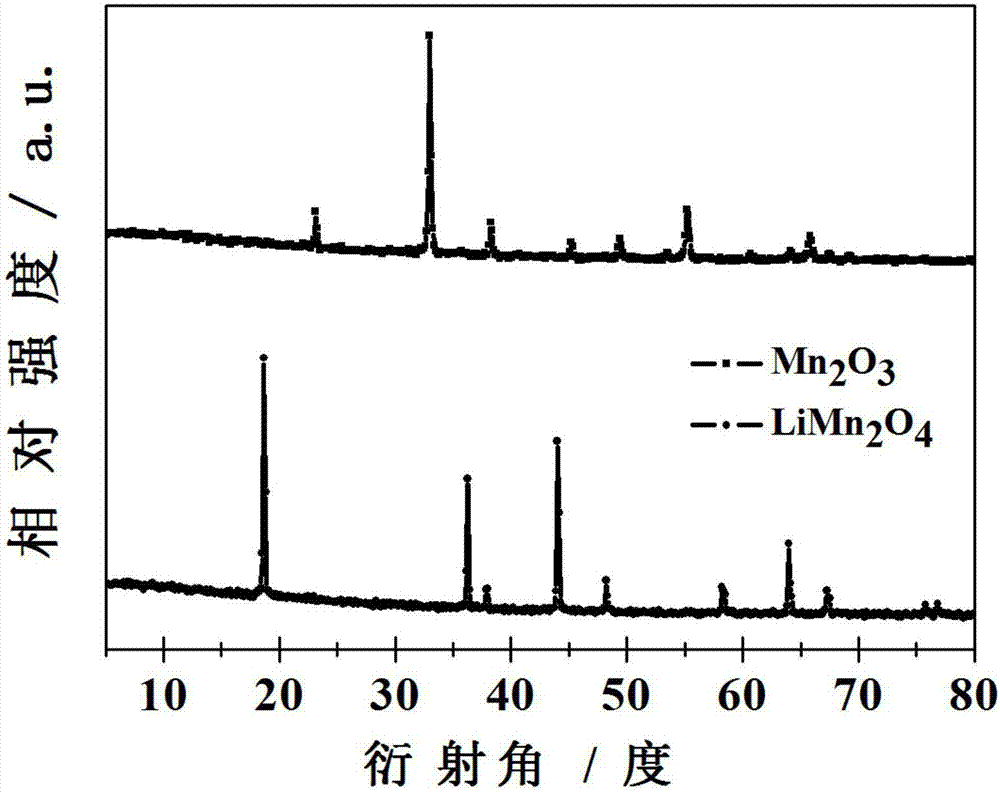

[0035] S1. Add cetyltrimethylammonium bromide to cyclohexane to obtain the first material; add manganese salt to the oxalic acid solution to obtain the second material; uniformly mix the first material and the second material to obtain the third material; The third material is heated until the volatilization is complete, and then solid-phase sintering is carried out to obtain the black product Mn 2 o 3 ;

[0036] S2, lithium salt, black product Mn 2 o 3 After mixing with the dispersant, grinding, drying, followed by solid phase sintering and cooling to obtain submicron lithium manganese oxide for lithium ion battery positive electrode.

Embodiment 2

[0038] A preparation method of submicron lithium manganese oxide for positive electrode of lithium ion battery, comprising the steps of:

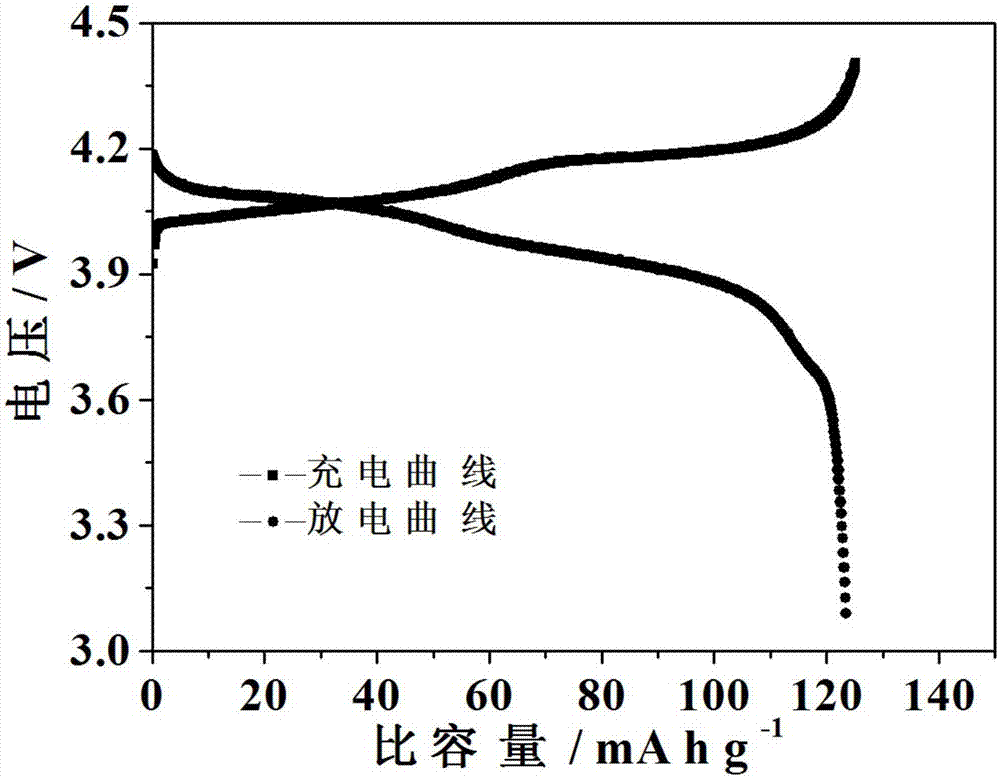

[0039] S1. Add cetyltrimethylammonium bromide to cyclohexane to obtain the first material with a concentration of 0.03g / mL; add manganese acetate dihydrate to an oxalic acid solution with a concentration of 0.8mol / L to obtain the second material , the concentration of manganese acetate in the second material is 0.12g / mL; the first material and the second material are mixed evenly to obtain the third material; Sintered for 5h to get the black product Mn 2 o 3 ;

[0040] S2, lithium hydroxide monohydrate, black product Mn 2 o 3 Mix with ethanol or acetone, lithium hydroxide monohydrate and black product Mn 2 o 3 The molar ratio is 1.02:1, grind for 35min, dry, then raise the temperature to 450°C, keep it for 5h, raise the temperature to 750°C, keep it for 7h, the heating rate is 4.5°C / min, and cool to obtain submicron manganic acid

Embodiment 3

[0042] A preparation method of submicron lithium manganese oxide for positive electrode of lithium ion battery, comprising the steps of:

[0043] S1. Add cetyltrimethylammonium bromide to cyclohexane to obtain the first material with a concentration of 0.05g / mL; add manganese acetate dihydrate to an oxalic acid solution with a concentration of 0.5mol / L to obtain the second material , the concentration of manganese acetate in the second material is 0.13g / mL; the first material and the second material are mixed evenly to obtain the third material; Sintered for 3h to get the black product Mn 2 o 3 ;

[0044] S2, lithium hydroxide monohydrate, black product Mn 2 o 3 Mix with ethanol or acetone, lithium hydroxide monohydrate and black product Mn 2 o 3 The molar ratio is 1.08:1, grind for 25min, dry, then raise the temperature to 500°C, keep it for 3h, raise the temperature to 850°C, keep it for 5h, the heating rate is 5.2°C / min, and cool to get submicron manganic acid fo

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap