Automobile part cleaning device and production technique of automobile parts

A technology for cleaning devices and auto parts, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability to circulate water and prevent slipping effects, poor filtering effects, etc., and achieve poor anti-slip effects and prevent Slipping, good effect of fixing the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

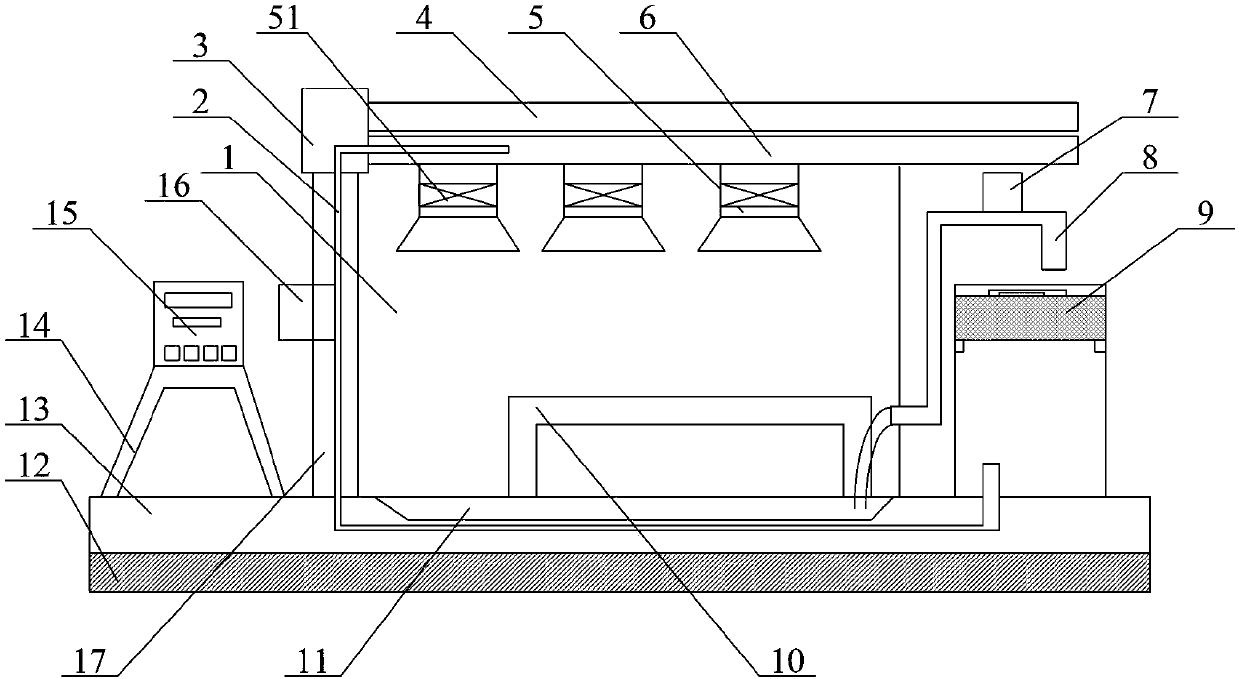

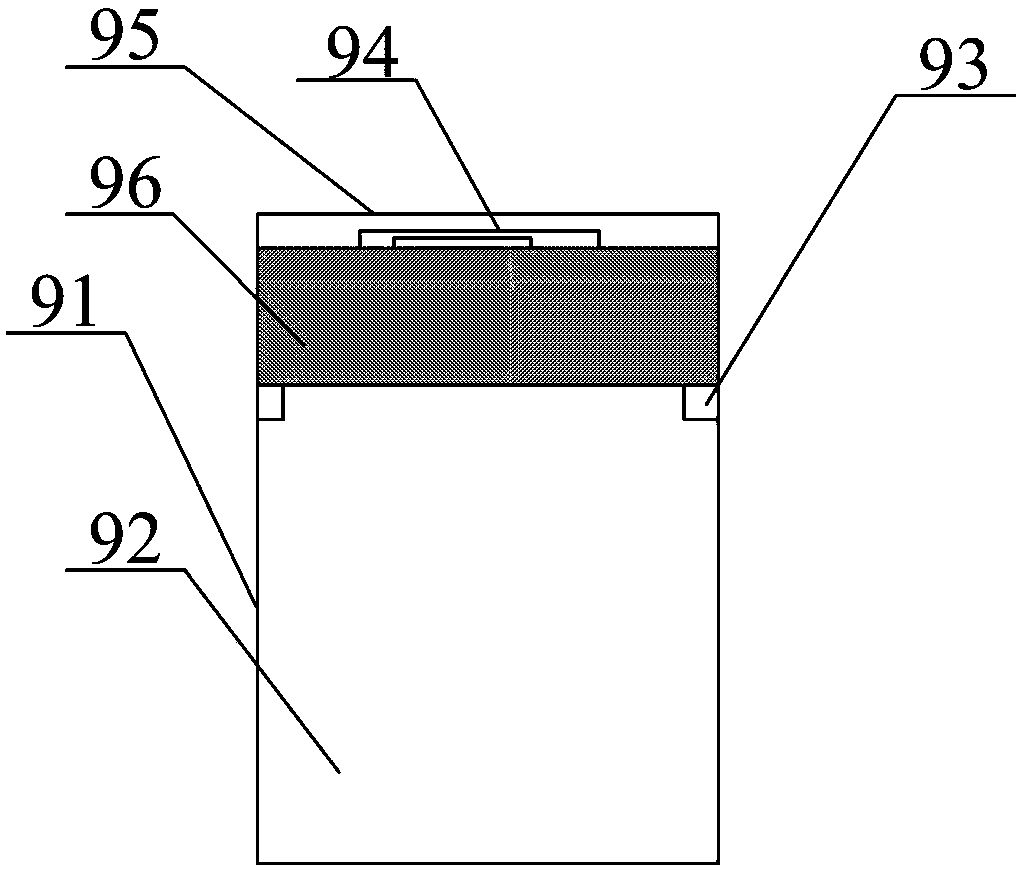

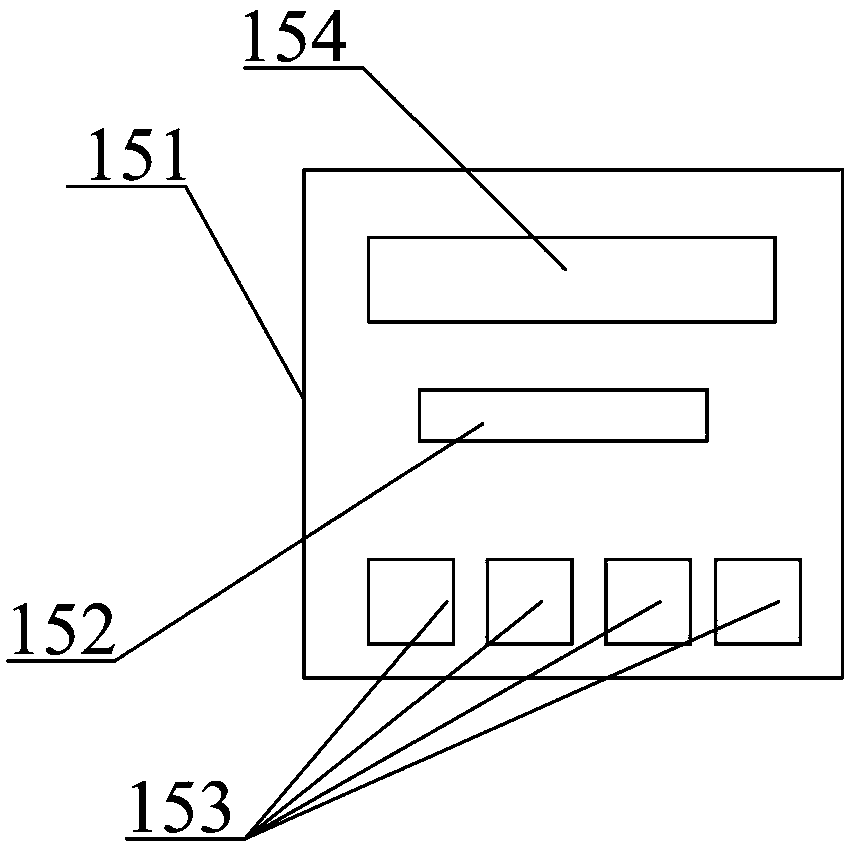

[0026] as attached figure 1 to attach image 3 shown

[0027] The invention provides an auto parts cleaning device and its production process, comprising a cleaning chamber 1, a primary connecting pipe 2, a connecting block 3, a connecting rod 4, a nozzle 5, a secondary connecting pipe 6, a pressure pump 7, a return pipe 8, and a filter box Structure 9, placing table 10, water flow tank 11, anti-slip mat 12, placing plate 13, placing frame 14, controller structure 15, water suction pump 16 and fixed rod 17, one end of the first-level connecting pipe 2 and the filter box structure 9 The lower part is connected, and the other end is connected with the secondary connecting pipe 6; the connecting block 3 is welded on the top of the fixed rod 17; the connecting rod 4 is welded on the right side of the connecting block 3; the nozzle 5 is threaded on the The lower part of the secondary connecting pipe 6; the secondary connecting pipe 6 is installed on the right side of the connecting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap