Low viscosity eye make-up cosmetic composition comprising wax

A composition and makeup technology, applied in cosmetics, cosmetics, cosmetic preparations, etc., can solve technical limitations and other problems, and achieve the effect of low viscosity, good staying power and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

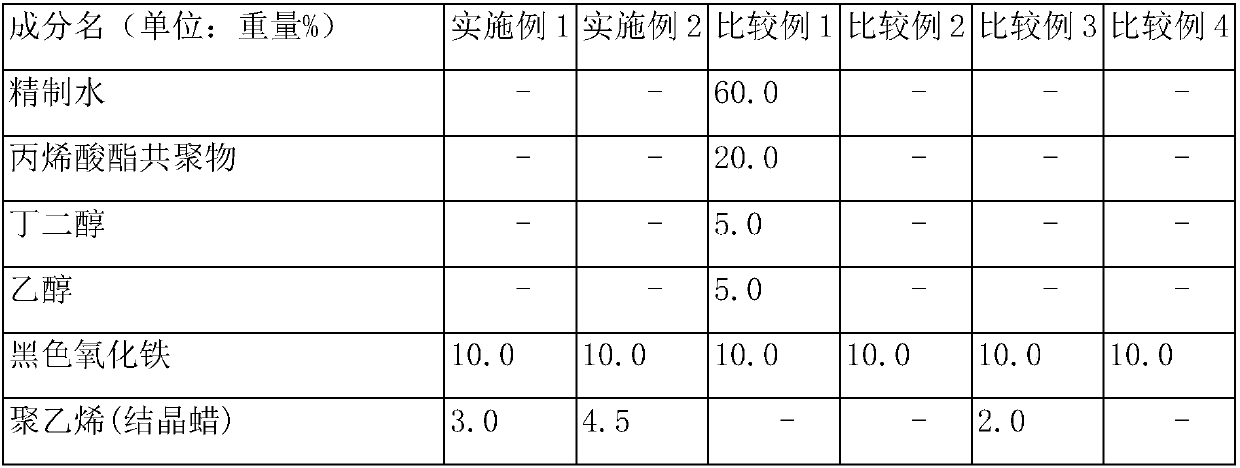

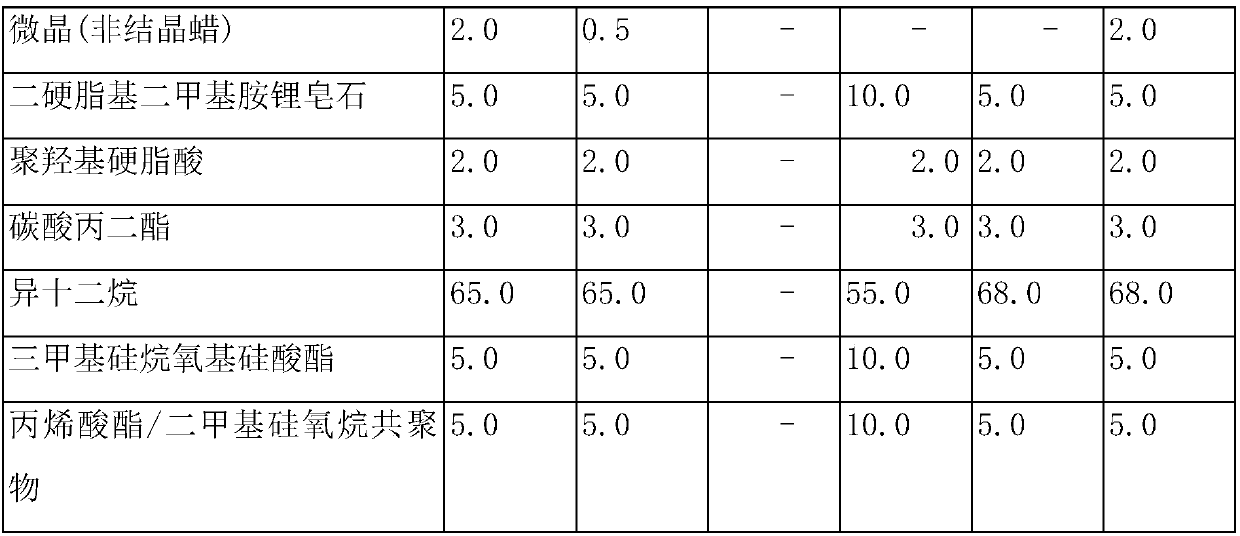

Embodiment 1~2 and comparative example 1~4

[0045] According to the compositions disclosed in Table 1 below, the eye makeup compositions of Examples 1-2 and Comparative Examples 1-4 were prepared. Specifically, the eye makeup composition is a soft pen type liquid eyeliner composition.

[0046] Examples 1-2 are eye makeup compositions of the present invention, which are dosage forms including both crystalline wax and non-crystalline wax. Specifically, in Example 1, the weight ratio of crystalline wax and non-crystalline wax is set to 3:2, and in Example 2, the weight ratio of crystalline wax to non-crystalline wax is set to 4.5:0.5, so that the wax in each example There are differences in content ratio.

[0047] Comparative Example 1 is a traditional eye makeup composition, which is a water-phase matrix formulation that does not contain wax and contains excess film-forming agent. Comparative Example 2 is an eye makeup composition of an oil-phase base dosage type that does not contain wax and contains an excessive amount o

experiment example 1

[0051] Experimental example 1: Jet force test

[0052] The viscosities of the compositions of Examples 1-2 and Comparative Examples 1-4 were measured, and when the above-mentioned compositions were applied to soft pen products, the ejection force of the compositions through the nozzle was evaluated.

[0053] The evaluation method used was to fill the soft pen eyeliner with the above-mentioned compositions of Examples 1-2 and Comparative Examples 1-4, respectively, and press the extraction part of the content until the brush head was wet, at which point the number of presses was measured.

[0054] The evaluation results are shown in Table 2 below.

[0055] Table 2

[0056] evaluation items

Example 1

Example 2

Comparative example 1

Comparative example 2

Comparative example 3

Comparative example 4

Viscosity(cps)

900

1,800

950

1,000

4,200

450

Number of injection presses

5

8

6

5

X

2

[0057] Refe

experiment example 2

[0059] Experimental example 2: Test of the degree of solidification on the surface of the brush head

[0060] After the compositions of Examples 1 to 2 and Comparative Examples 1 to 4 were sprayed onto the surface of the soft pen brush head, the degree of solidification on the surface of the brush head was confirmed. The evaluation method is as follows.

[0061] assessment method

[0062] - After leaving the soft pen eye makeup product used more than 10 times for 3 days (the surface of the brush head is in a dry state), perform the above-mentioned spray force test and measure the number of presses used for rewetting the surface of the brush head.

[0063] -◎: The number of re-presses is within 5 times, ○: The number of re-presses is 6 to 10 times, △: The number of re-presses is 11 to 15 times, X: The number of re-presses is more than 16 times. degree of coagulation.

[0064] - The less the number of re-presses, the less the degree of coagulation of the surface of the brush hea

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap