Compound semiconductor silicon-based mixer device and preparation method thereof

A semiconductor and compound technology, applied in the field of compound semiconductor silicon-based hybrid devices and its preparation, can solve the problems of difficult alignment and complicated preparation process, and achieve the effects of improving efficiency, improving coupling efficiency, and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

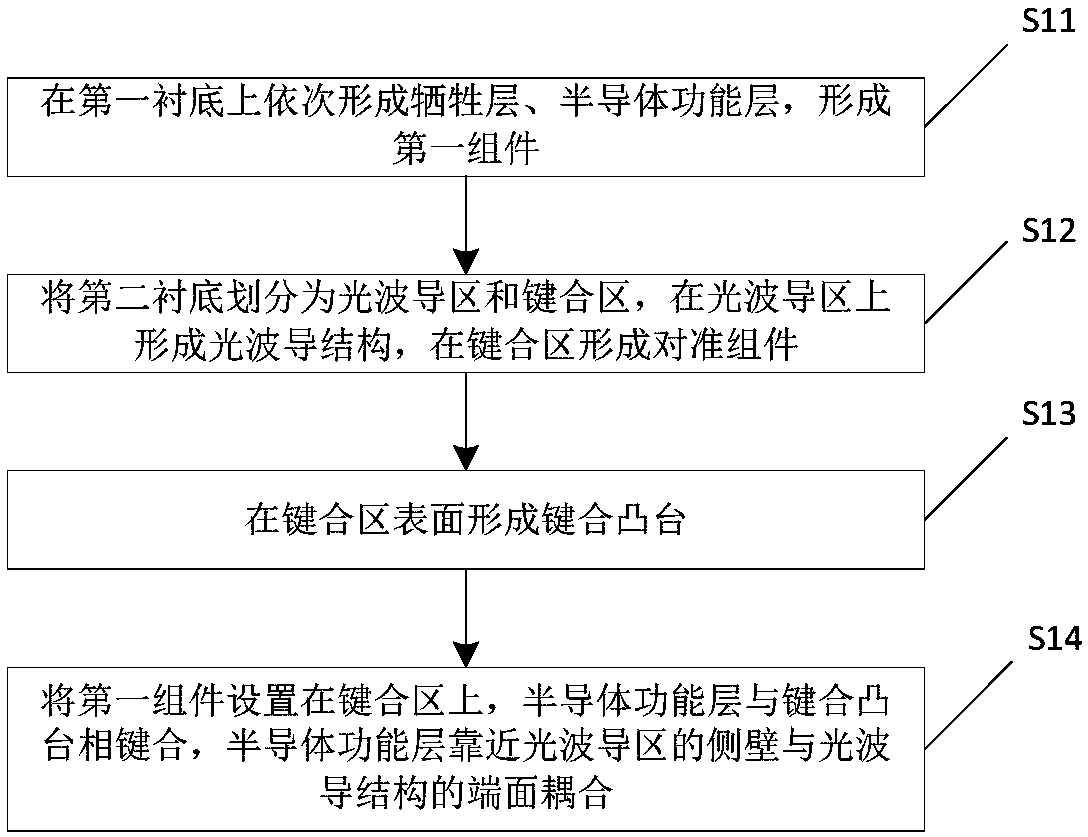

[0037] An embodiment of the present invention provides a method for preparing a compound semiconductor silicon-based hybrid device, which is used to prepare a silicon-based compound semiconductor hybrid integrated device, such as figure 1 Shown, this preparation method comprises the following steps:

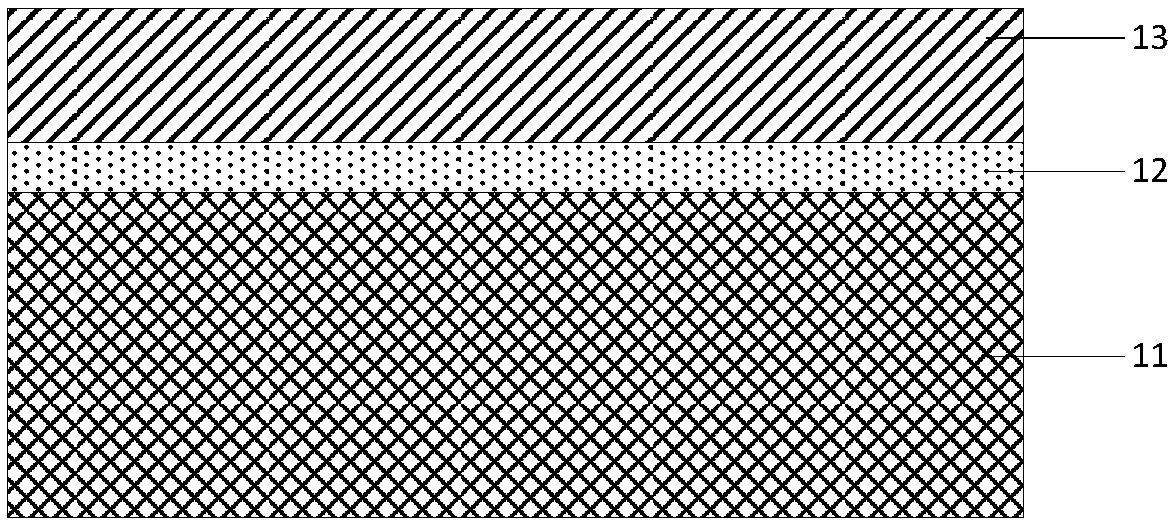

[0038] Step S11 , sequentially forming a sacrificial layer and a semiconductor functional layer on the first substrate to form a first component.

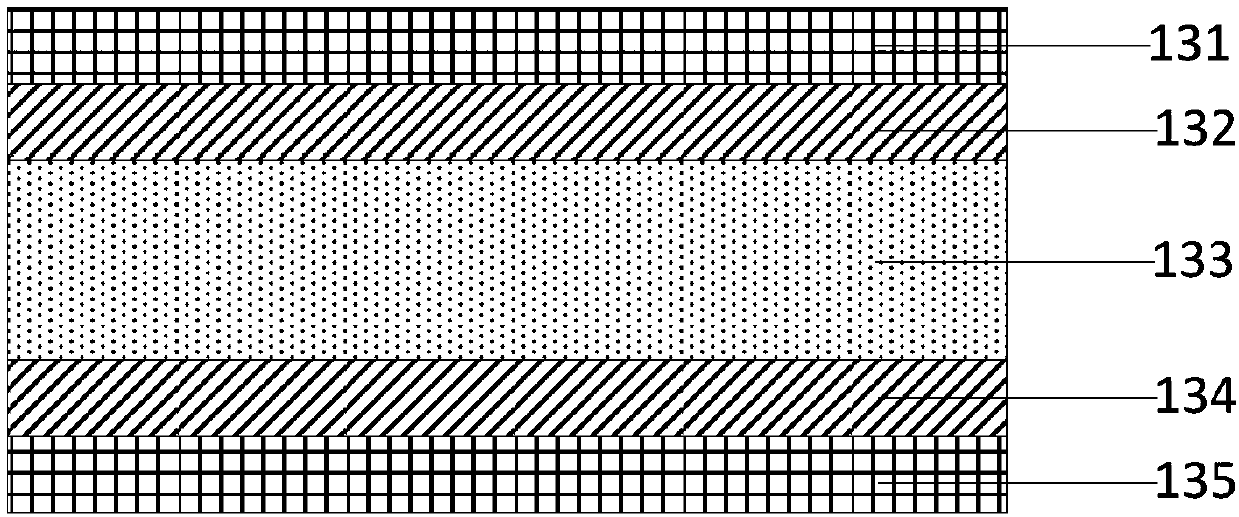

[0039] Such as figure 2 As shown, a sacrificial layer 12 is first grown on a first substrate 11 by molecular beam epitaxy (Molecular Beam Epitaxy, referred to as MBE) or metal-organic chemical vapor deposition (Metal-organic Chemical Vapor Deposition, referred to as MOCVD). A semiconductor functional layer (light gain and absorption structures such as semiconductor lasers, semiconductor optical amplifiers, and semiconductor photodetectors) 13 is grown on the layer 12 to form a first component. However, the protection scope of the pres

Embodiment 2

[0072] An embodiment of the present invention provides a silicon-based compound semiconductor hybrid integrated device, which is prepared by using the method for preparing a compound semiconductor silicon-based hybrid device in Embodiment 1 of the present invention.

[0073] For details of the structure of the compound semiconductor bulk silicon-based hybrid device not specifically described in this embodiment, please refer to Embodiment 1, and details will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap