SLM powder recycling device

A recovery device and powder technology, which is applied in the field of additive manufacturing, can solve the problems of time-consuming and cumbersome steps, and achieve the effects of reducing environmental pollution, reducing powder waste, and improving powder screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

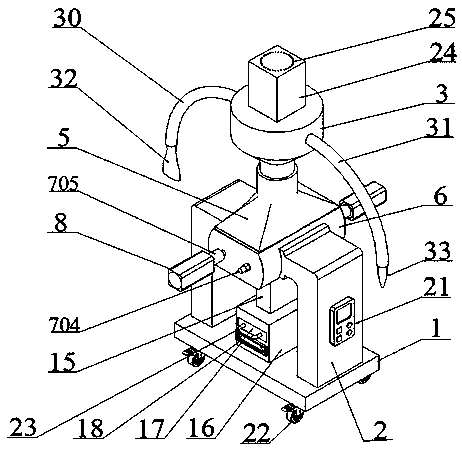

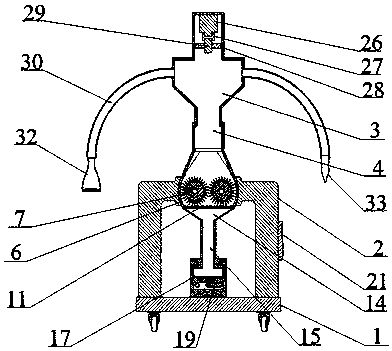

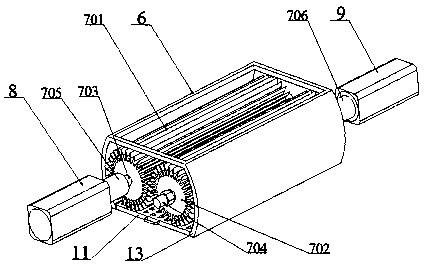

[0037] Embodiment 1: as Figure 1~9 As shown, a recovery device for SLM powder, including a base 1, two supporting columns 2, a powder falling chamber 3, a powder falling channel 4, a diffusion channel 5, a powder sieving chamber 6, and a rotating powder sieving scraper member 7 , screen 11, powder beam channel 14, powder collection channel 15, powder collection box 16, powder collection drawer 17, heating chamber 18, controller 21, 4 universal wheels 22, vacuum studio 24, powder suction pipe I30, Powder suction pipe Ⅱ31;

[0038] Four universal wheels 22 are respectively arranged on the four corners of the lower surface of the base 1, two support columns 2 are respectively arranged on both sides of the top of the base 1, and the powder sieving chamber 6 is fixedly arranged on the top of the support column 2 and outside the powder sieving chamber 6 The wall is connected with the ends of the two support columns 2, and the inner walls of the left and right sides of the bottom of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap