Efficient preparing method of nickel plate

A nickel plate, high-efficiency technology, applied in the field of high-efficiency preparation of nickel plate, can solve the problems of improving the quality of nickel plate, and achieve the effects of improving quality, improving production efficiency, and increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

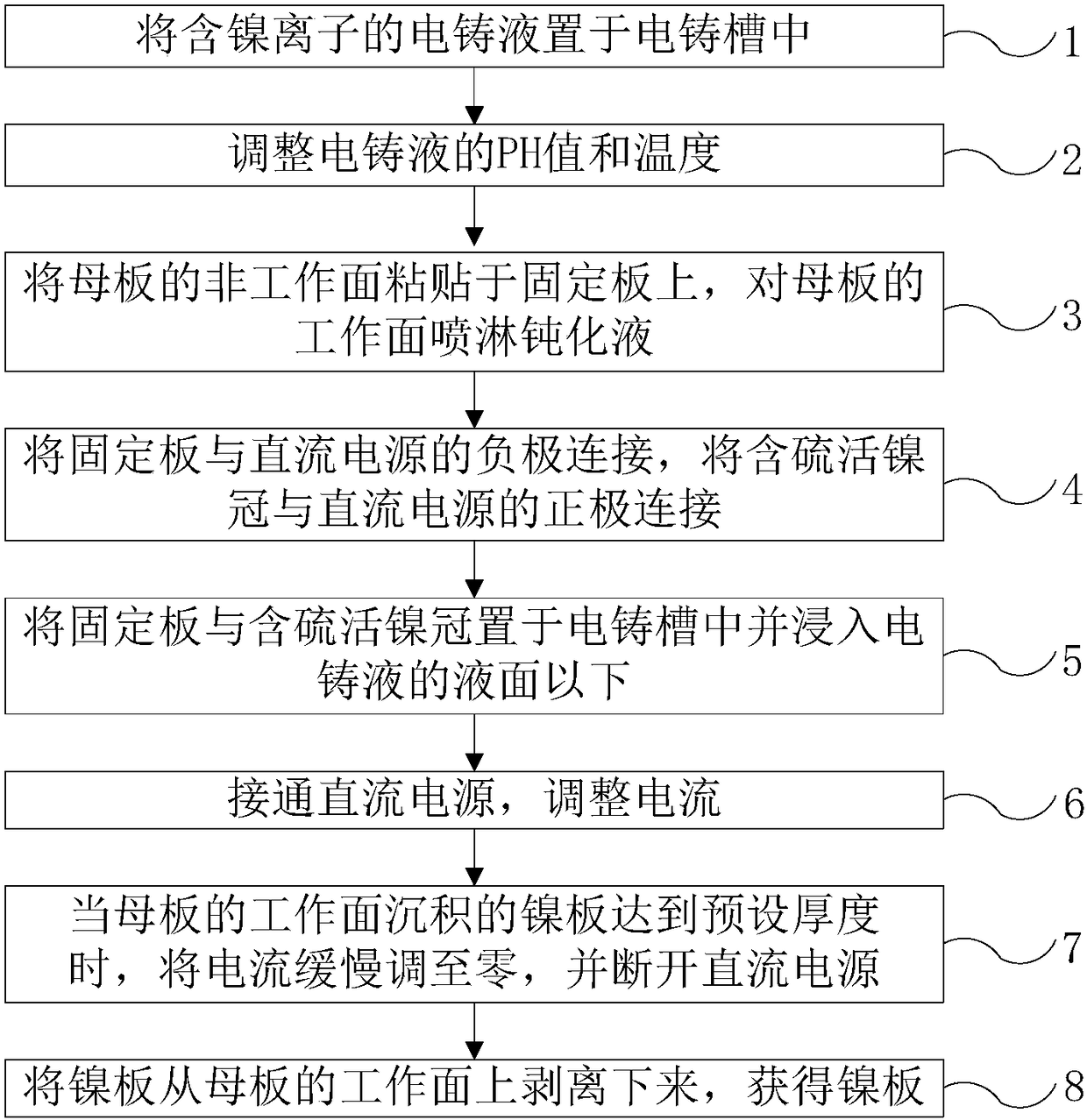

[0043] Please refer to the attached figure 1 , which is a flow chart of a method for efficiently preparing a nickel plate provided in this embodiment. The method comprises the steps of:

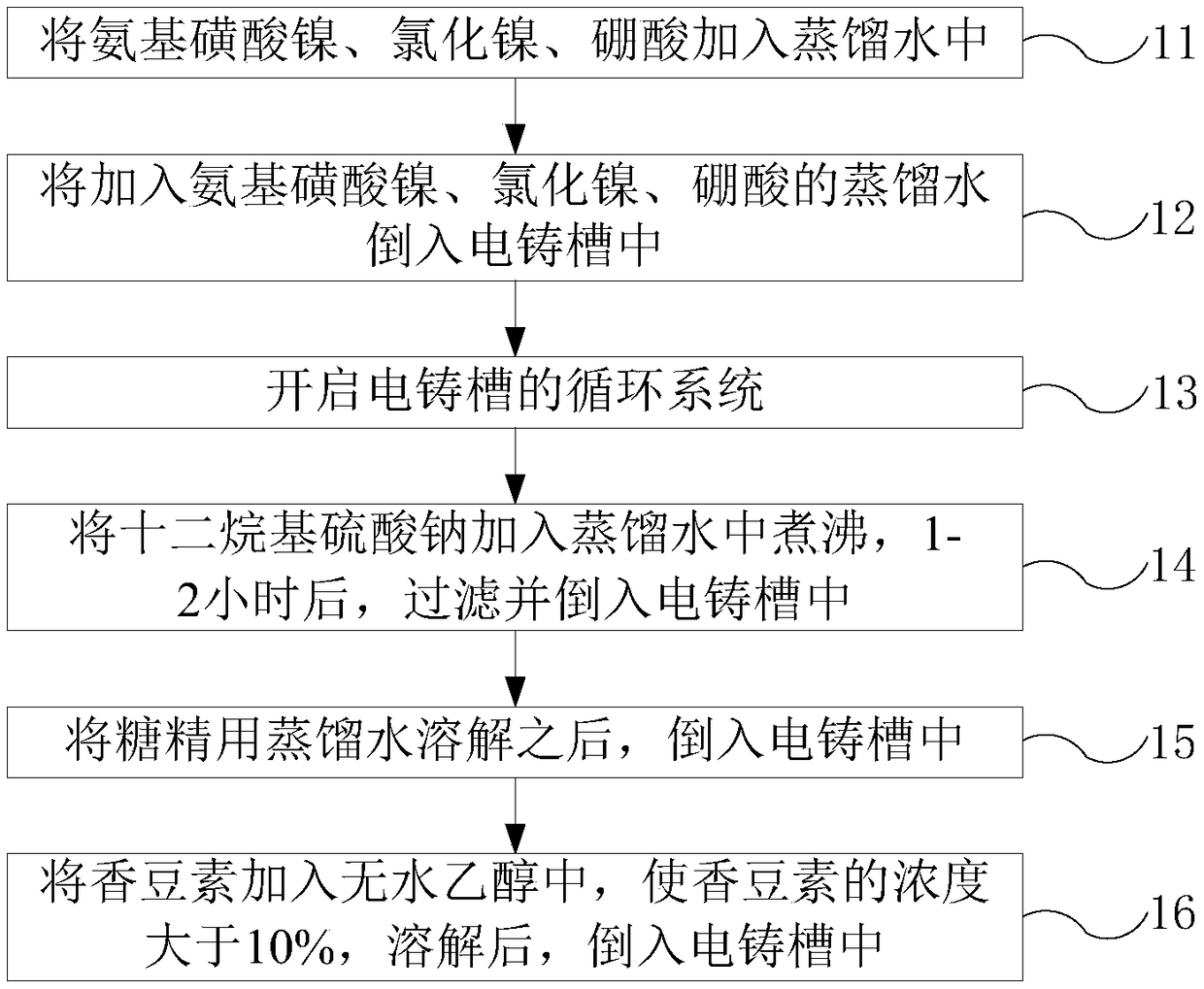

[0044] Step 1, place the electroforming solution in the electroforming tank, wherein each liter of electroforming solution includes 300-400g nickel sulfamate, 4-15g nickel chloride, 30-35g boric acid, 0.08-0.12g dodecyl Sodium sulfate, 0.009-0.011g saccharin and 0.009-0.011g coumarin.

[0045] Nickel sulfamate mainly provides nickel ion in electroforming process, and the concentration of nickel sulfamate in electroforming solution is 300-400g per liter in the present embodiment, and concentration is relatively high, can allow to adopt higher current density, deposition The speed is fast, and the color of the coating is uniform, thereby increasing the preparation efficiency and improving the quality of the casting.

[0046] In the electroforming solution, nickel chloride as an anode activator

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap