Turning and grinding tool for inner holes of bearing seat

A bearing seat and turning grinding technology, which is applied in the direction of grinding workpiece brackets, supports, positioning devices, etc., can solve the problems of insufficient machining accuracy of the inner hole, insufficient position, deformation of the workpiece, etc., and achieve simple structure, simple pressing method, The effect of increasing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

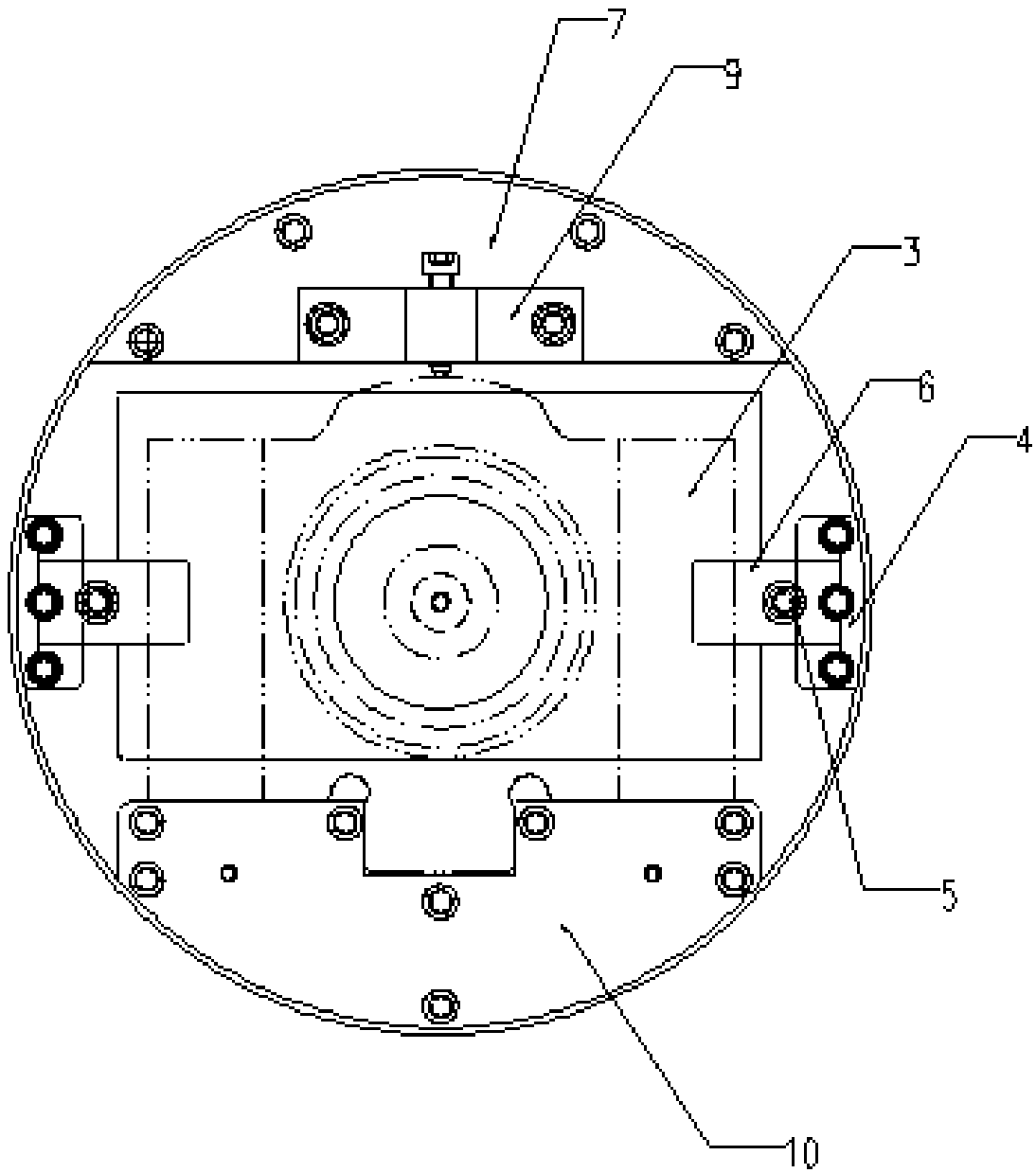

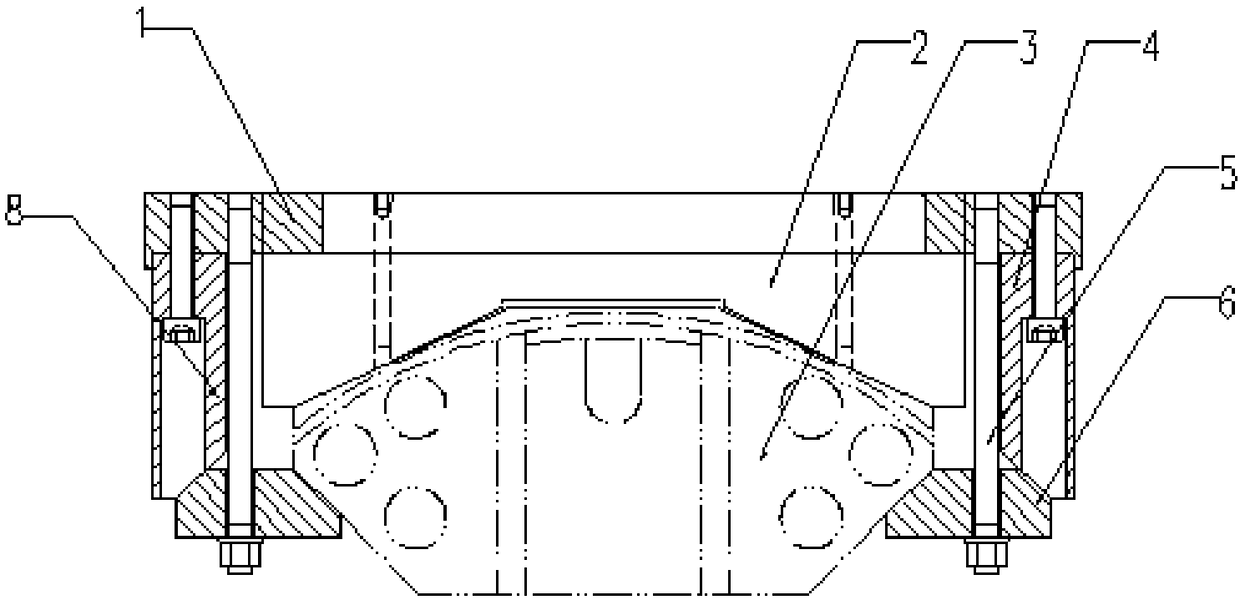

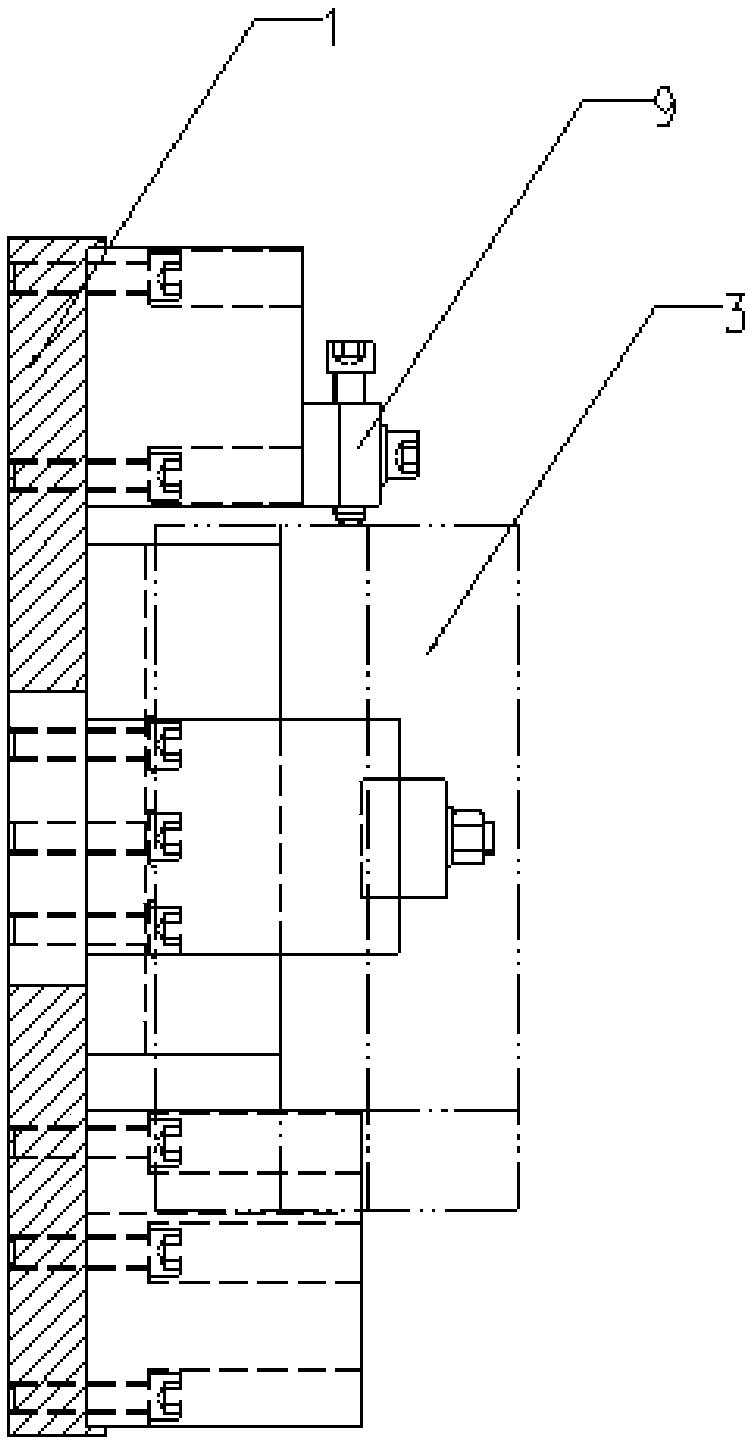

[0021] figure 1 It is a plan view of the present invention. figure 2 It is a front view of the present invention. image 3 It is the right side view of the present invention. set up figure 1 The two mutually perpendicular directions on the plane are the first direction and the second direction. set up figure 2 The two directions perpendicular to each other on the plane are the second direction and the third direction.

[0022] The bearing seat 3 is a workpiece installed in the tooling, one side of which is arc-shaped, and the other side has slope structures on both sides, which is the fourth slope.

[0023] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a coupling flange 1 . It also includes a V-shaped iron 2 fixed on the connecting flange 1. One side of the V-shaped iron 2 is close to the connecting flange 1, and the other side is a concave structure similar to a V shape, and its lowest point includes a plane, and the side of the pla

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap