Process for recovering and reusing waste motorcycle shells

A technology for motorcycles and shells, which is applied in the field of recycling and reuse of waste motorcycle shells. It can solve the problems of damaging the environment and endangering the health of the people, and achieves the effects of enhancing environmental performance, easy disposal, and good paint removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

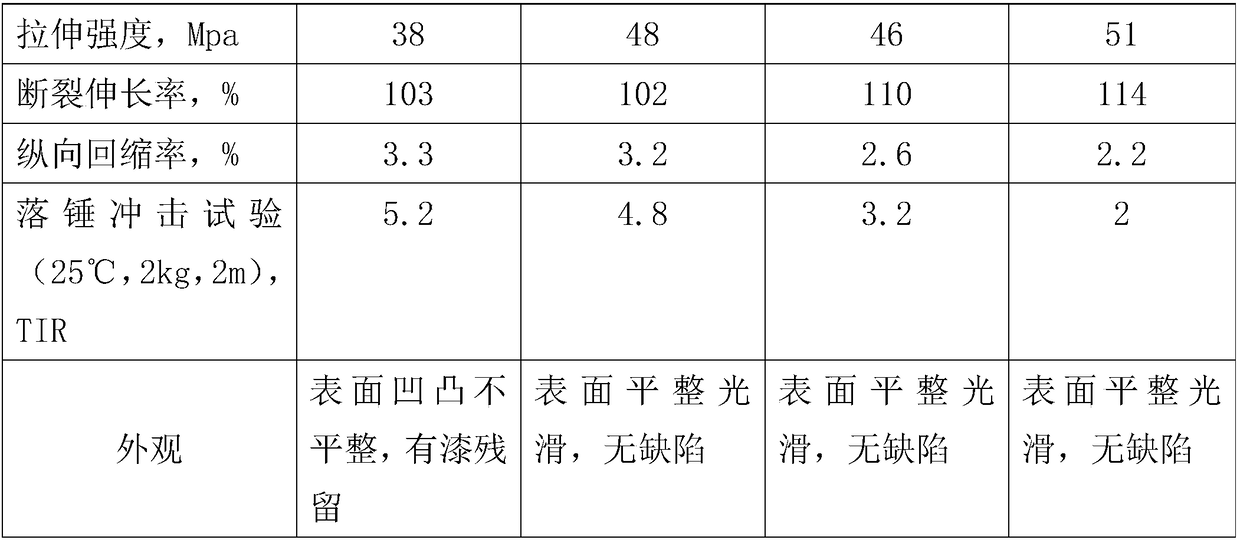

Embodiment 1

[0023] A recycling process for waste motorcycle shells, the specific process steps are as follows:

[0024] (1) Put the collected motorcycle casings into the crusher for crushing, then put the crushed materials into the paint remover, and the processing time is 1 hour;

[0025] The paint removal solution is made from the following raw materials in parts by weight: 10 parts of acetone, 5 parts of nitric acid, 4 parts of hydrofluoric acid, 3 parts of ammonium dichloride, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 2 parts of copolymer, 60 parts of absolute ethanol;

[0026] (2) Perform high-pressure spray cleaning on the soaked crushed material with a cleaning agent, and the spray time is 10 minutes;

[0027] The cleaning agent is made of the following raw materials in parts by weight: 100 parts of water, 10 parts of salt, 20 parts of 75% ethanol, 10 parts of hydrogen peroxide, and 5 parts of sodium hydroxide;

[0028] (3) Drain the cleaned crushed material, put it int

Embodiment 2

[0035] A recycling process for waste motorcycle shells, the specific process steps are as follows:

[0036] (1) Put the collected motorcycle shell into the crusher for crushing, then put the crushed material into the paint removal solution, raise the temperature to 70 degrees, and carry out the paint removal and softening treatment under the ultrasonic power of 800W. The processing time is 2 hours, then put it in a centrifuge, and process it for 15 minutes with a speed of 2000r / min;

[0037] The paint remover is made from the following raw materials in parts by weight: 20 parts of acetone, 15 parts of nitric acid, 8 parts of hydrofluoric acid, 8 parts of ammonium dichloride, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 5 parts of copolymer, 80 parts of absolute ethanol;

[0038] (2) Perform high-pressure spray cleaning on the soaked crushed material with a cleaning agent, and the spray time is 20 minutes;

[0039] The cleaning agent is made of the following raw mate

Embodiment 3

[0045] A recycling process for waste motorcycle shells, the specific process steps are as follows:

[0046](1) Put the collected motorcycle shell into the crusher for crushing, then put the crushed material into the paint removal solution, raise the temperature to 70 degrees, and carry out the paint removal and softening treatment under the ultrasonic power of 700W. The processing time is 2 hours, then put it in a centrifuge, and process it for 15 minutes with a speed of 2000r / min;

[0047] The paint remover is made from the following raw materials in parts by weight: 15 parts of acetone, 10 parts of nitric acid, 6 parts of hydrofluoric acid, 5 parts of ammonium dichloride, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 4 parts of copolymer, 70 parts of absolute ethanol;

[0048] (2) Perform high-pressure spray cleaning on the soaked crushed material with a cleaning agent, and the spray time is 15 minutes;

[0049] The cleaning agent is made of the following raw mater

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap